Bionic sub-soiling shovel with drag-reduction bionic surface

A technology of deep loosening shovel and bionic bulge, which is applied in the field of bionic deep loosening shovel, can solve the problems of high operating cost, reducing the effect of deep loosening operation, and increasing the cost of agricultural operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

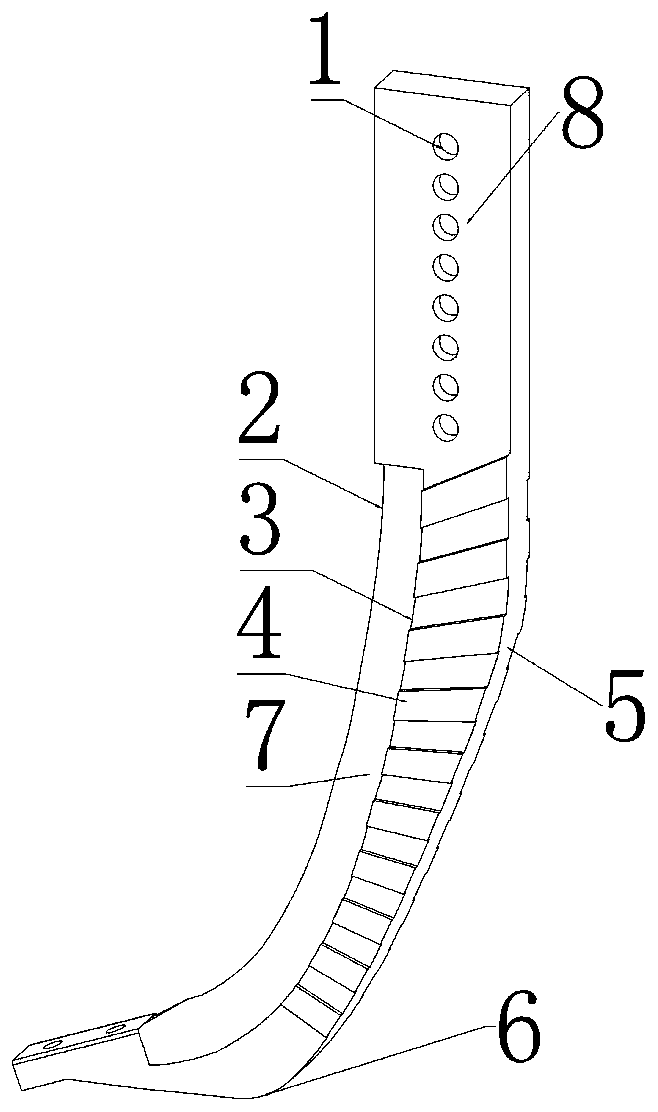

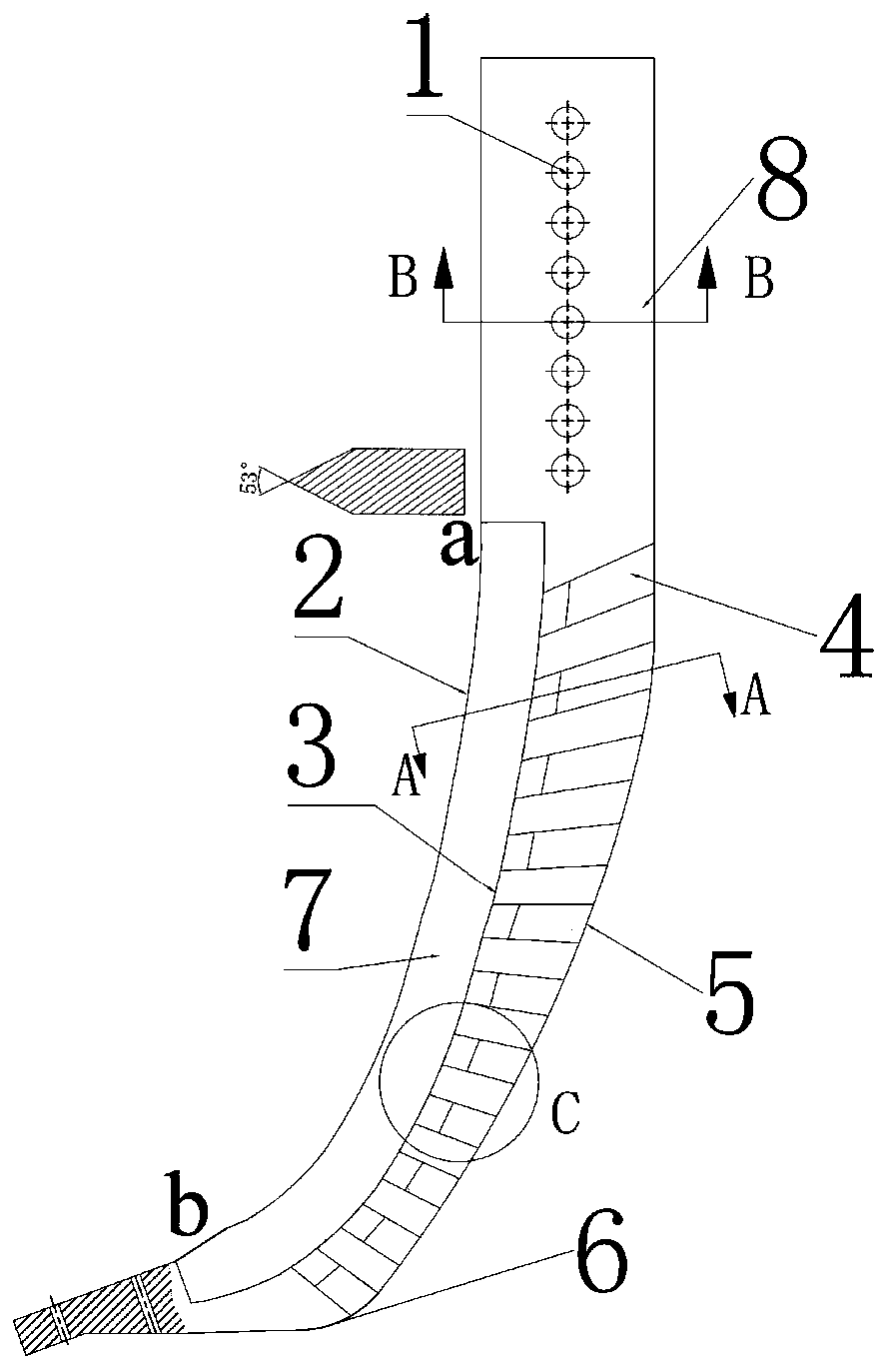

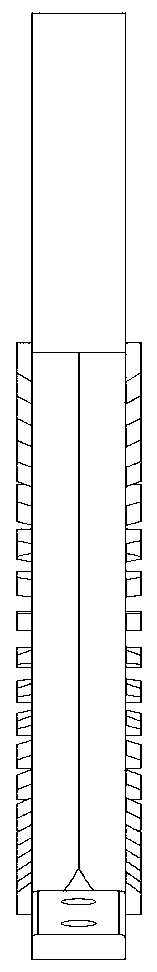

[0022] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a blind hole 1, an edge front contour line 2, an inner alignment line 3, a bionic raised rib structure 4, a first arc 5, a second arc 6, an edge curved surface 7 and a shovel body 8 ;

[0023] Such as figure 1 and Figure 5 As shown, eight blind holes 1 are arranged at a certain distance on the midline above the shovel body 8, and the aperture is The distance between the center of the blind hole and the left side of the shovel body is 40mm, and the distance from the top surface is 30mm. The distance between the two blind holes is 23mm. The blind hole 1 is fixed on the frame by two bolts for the shovel body. 8 is fixed, the depth of the shovel body is achieved by adjusting and fixing different blind holes 1, the depth of plowing adjustment is 20-45mm, and different depths are selected according to the different soil conditions of the operation.

[0024] Such as figure 2 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com