High-speed sailing vehicle combing micro-bubble drag reduction technology and groove surface turbulence drag reduction technology

A technology of aircraft and micro-bubbles, applied in the direction of hydrodynamic characteristics/hydrostatic characteristics, ships, hulls, etc., to reduce resistance, improve drag reduction efficiency, and improve rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

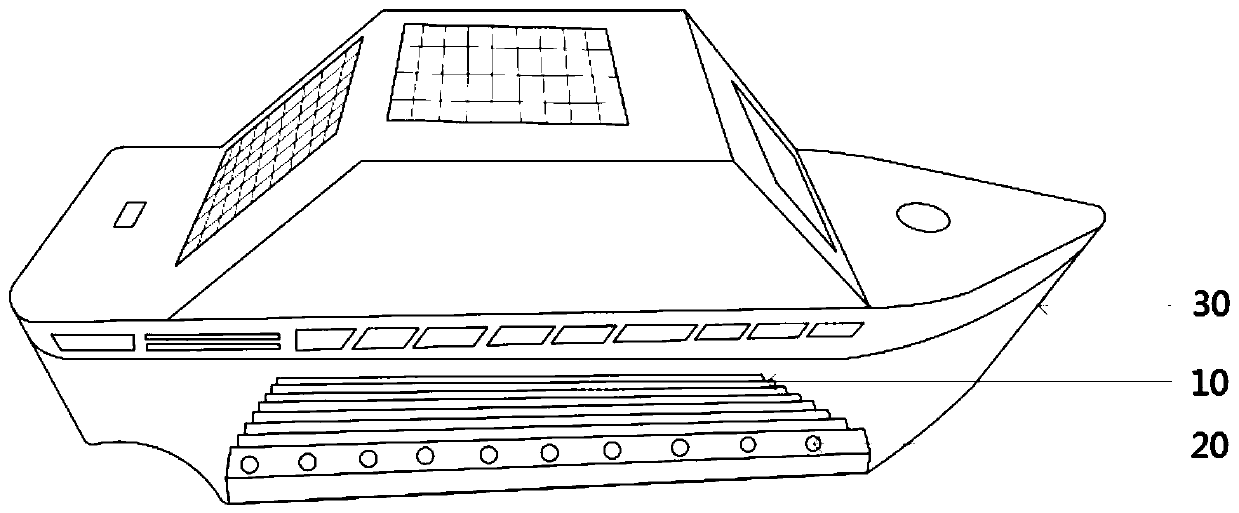

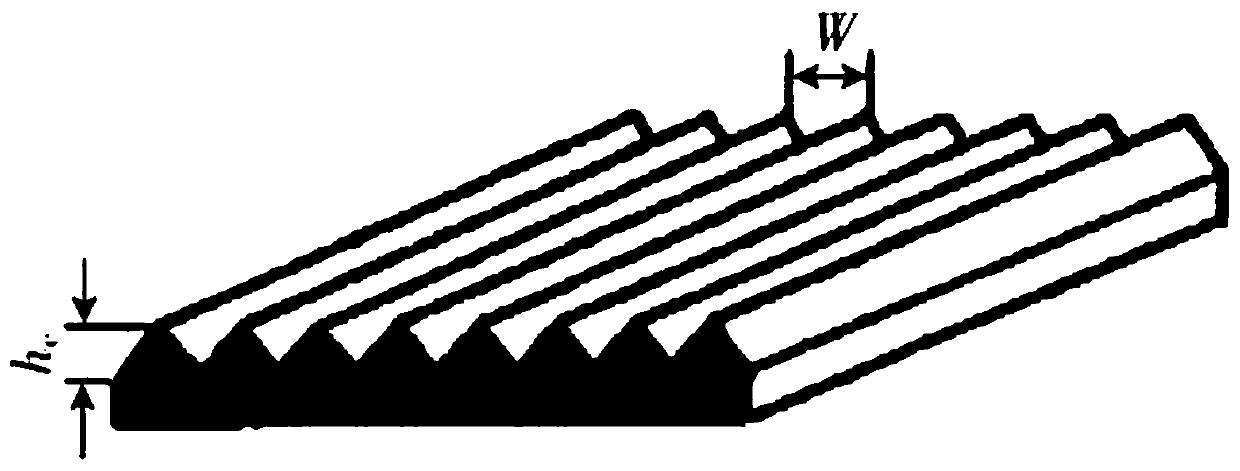

[0018] Such as figure 1 As shown, it is a high-speed aircraft combined with microbubble drag reduction technology and groove surface turbulent drag reduction technology in a preferred embodiment of the present invention. The bottom surface of the hull 30 of the high-speed aircraft is provided with several parallel grooves along the length of the ship. 10. The cross section of the groove 10 is square, U-shaped or V-shaped, and the groove height hc of the groove 10 is equal to the groove width W, and the range of the groove width W is: 25 μm≤W≤300 μm. The high-speed aircraft also includes a micro-bubble generating device arranged in the engine room. The micro-bubble generating device generates bubbles and transports them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com