Speedboat and manufacturing method thereof

A manufacturing method and speedboat technology, applied in the direction of warships, ship construction, ship parts, etc., can solve the problems of increased production cost, complicated manufacturing process, easy deformation of the hull, etc., and achieve the goal of not easily deformed, less splashing, and less labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

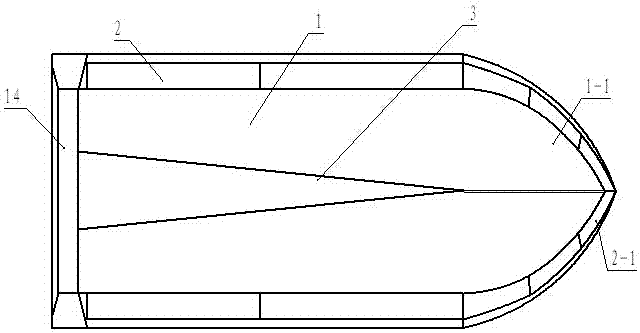

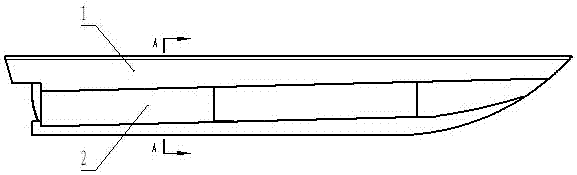

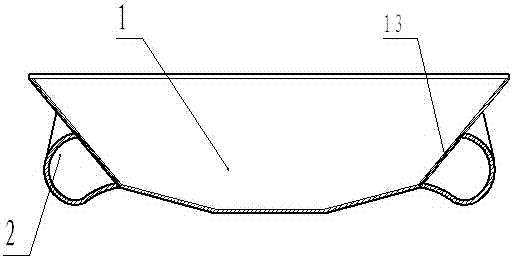

[0025] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

[0026] Such as Figure 1-Figure 3 As shown, the present embodiment includes a hull 1, and the two sides of the hull are symmetrically provided with buoys 2 along the knuckle lines of the hull. The buoys are closed long tanks with cavities inside. Bending downwards, the middle and rear part of the buoy 2 is attached to both sides of the hull 1 and slopes downward along the tail of the hull. The tail section of the buoy is lower than the waterline of the hull 1. When floating statically, the buoy is partially immersed in water and increases Lateral stability; because the bottom of the outer surface of the pontoon is bent downward, the bottom of the pontoon and the bottom of the hull form a wave dissipation channel. When the speed increases, the pontoon gradually jumps out of the water surface, reducing resistance and achieving the goal of fast driving; the ponto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com