Composite gas drag reducer and preparation method thereof

A natural gas and composite technology, which is applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve the problems of corrosion and aging of natural gas pipelines, reduced service life of natural gas pipelines, and increased safety hazards, and achieves obvious energy-saving effects. The effect of low equipment requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, preparation composite type natural gas drag reducer

[0029] Add 16.6g (0.1mol) of phthalic acid and 20.6g (0.2mol) of diethylenetriamine into a 250ml three-necked flask, under the protection of inert gas, stir and control the reaction temperature to 190°C, and react for 4h. When almost no water is produced (about 3.6g of water is produced at this time), the reaction is stopped, and when the temperature drops below 100°C, add 58.4g (0.2mol) of oleic acid that has been weighed into a 250ml reactor. Under the protection of an inert gas, the stirring temperature was controlled at 190° C., and the reaction was continued for 4 h. When almost no water is produced (about 3.6g of water is produced at this time), the reaction is stopped, and the crude product is poured out when the cooling temperature is lower than 100°C. Dissolving the crude product in alcohol can be used as a composite natural gas pipeline drag reducer.

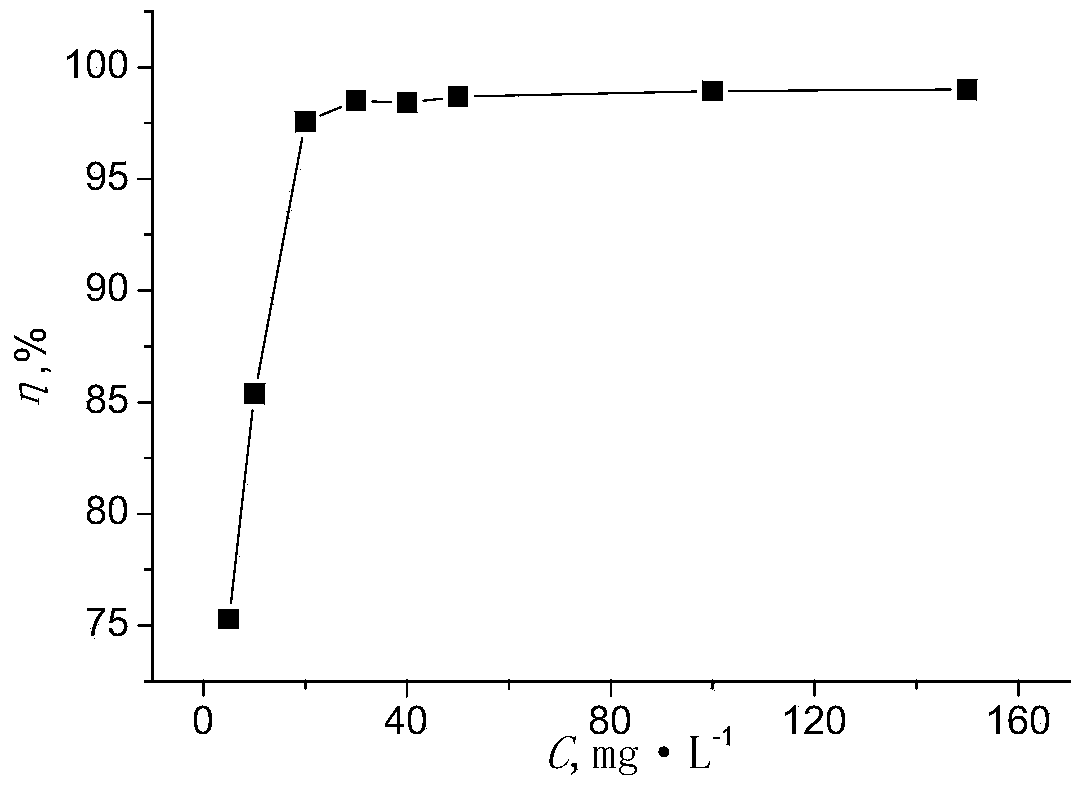

[0030] A small amount of the composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com