A drag reduction device and drag reduction method based on periodic stepped cylinder

A drag reduction device and periodic technology, applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of high cost, reduce the resistance of the rotating shaft, can not be obtained, etc., achieve significant drag reduction effect, reduce resistance, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

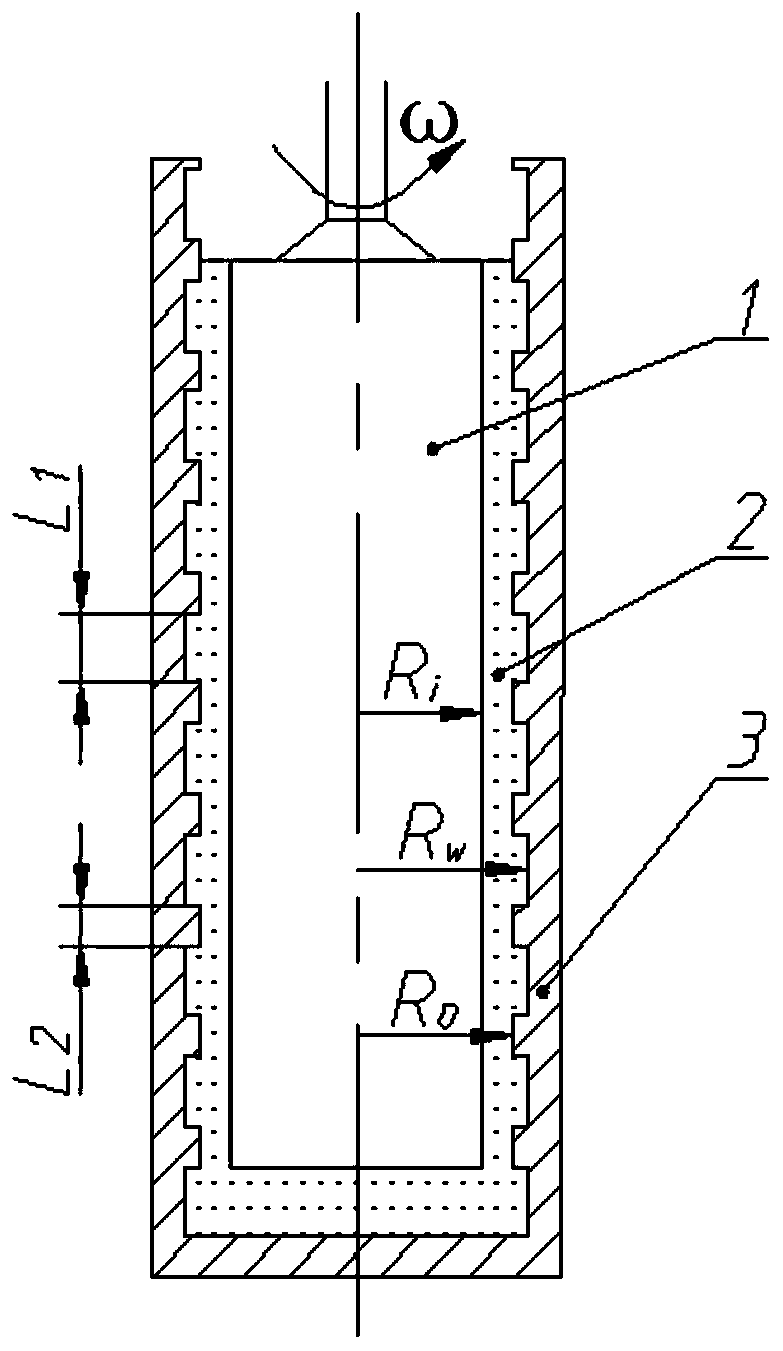

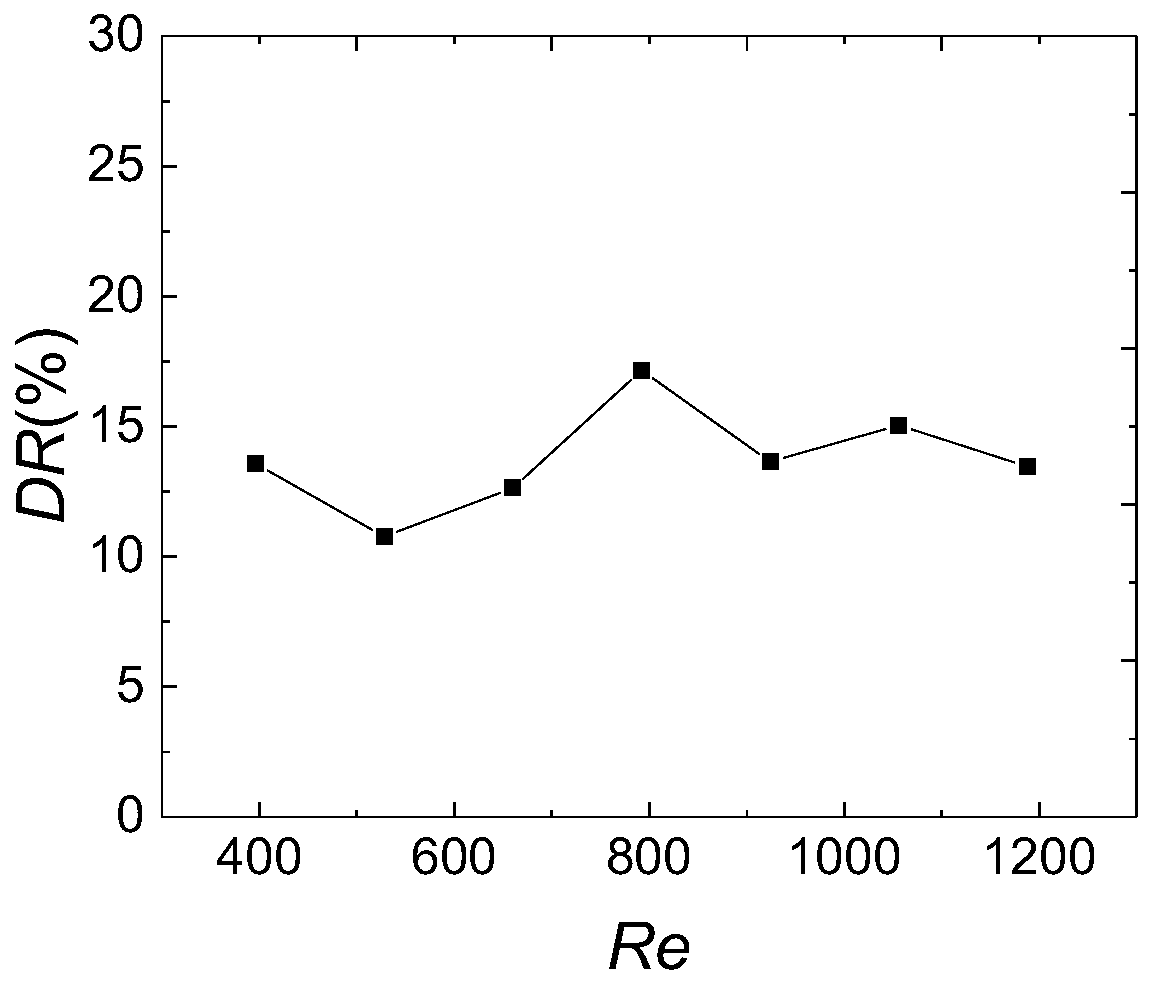

[0026] This embodiment is a drag reducing device and a drag reducing method based on a periodic stepped cylinder; the drag reducing device and the drag reducing method are based on the periodicity of the Taylor vortex rotating in reverse under the Taylor-Couette flow condition, changing the size of the Taylor vortex , to reduce the number of large-sized Taylor vortices, by arranging periodic cylindrical surfaces with different radii in the axial direction on the inner surface of the sleeve, the size and number of Taylor vortices are modulated, so that the size of Taylor vortices changes, and the number of large-sized Taylor vortices decreases, so that Reduce the resistance of the shaft. When the shaft is rotating, the circumferential flow of lubricating liquid between the shaft and the bushing belongs to Taylor-Couette flow, because the size of a pair of counter-rotating Taylor vortices is equal to twice the gap between the shaft and the bushing. When the size of a pair of cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com