Drag-reduction film composition

A technology of composition and initiator, applied in drilling composition, production fluid, wellbore/well components, etc., can solve the problem of high friction resistance of water-carrying sand pumping, and achieve good fluidity and strong affinity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

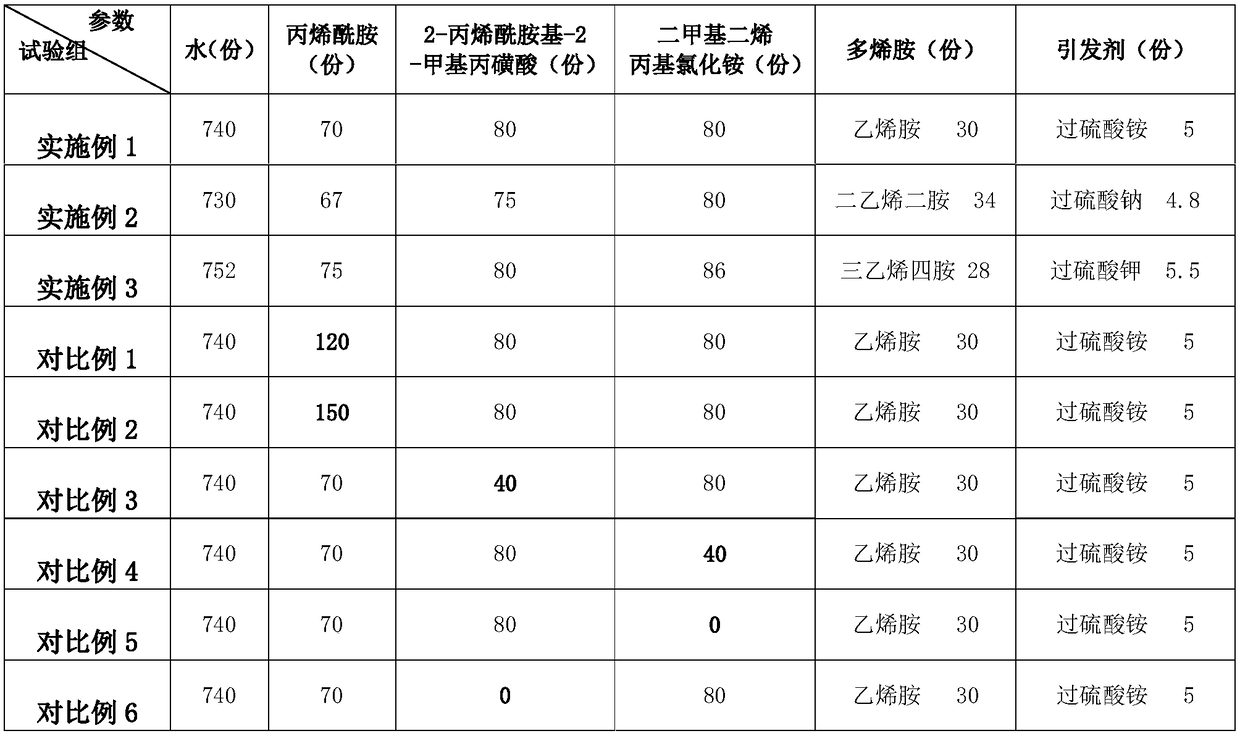

Embodiment 1

[0018] This example discloses a drag reducing film composition, which is prepared by using the following raw materials in parts by mass: 740 parts of water, 70 parts of acrylamide, 80 parts of 2-acrylamido-2-methylpropanesulfonic acid, polyene 30 parts of amine, 80 parts of dimethyl diallyl ammonium chloride and 5 parts of initiator; wherein the initiator is selected from ammonium persulfate, and the polyenylamine is selected from vinylamine. The drag reducing film composition may also include the following raw materials, 1% sodium hydroxide solution.

[0019] The above-mentioned drag reducing film composition is prepared by the following method:

[0020] (1) Add water in the reactor and heat up to 70°C;

[0021] (2) Stir the materials in the reactor, add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, vinylamine, dimethyl diallyl ammonium chloride to the reactor in turn, after the raw materials are added , continue stirring for 20 minutes and then stop;

[0022] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com