A non-volute centrifugal fan with drag-reducing groove

A technology of centrifugal fan and drag reducing groove, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of low frictional resistance on the blade surface, affecting fan performance, flow loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

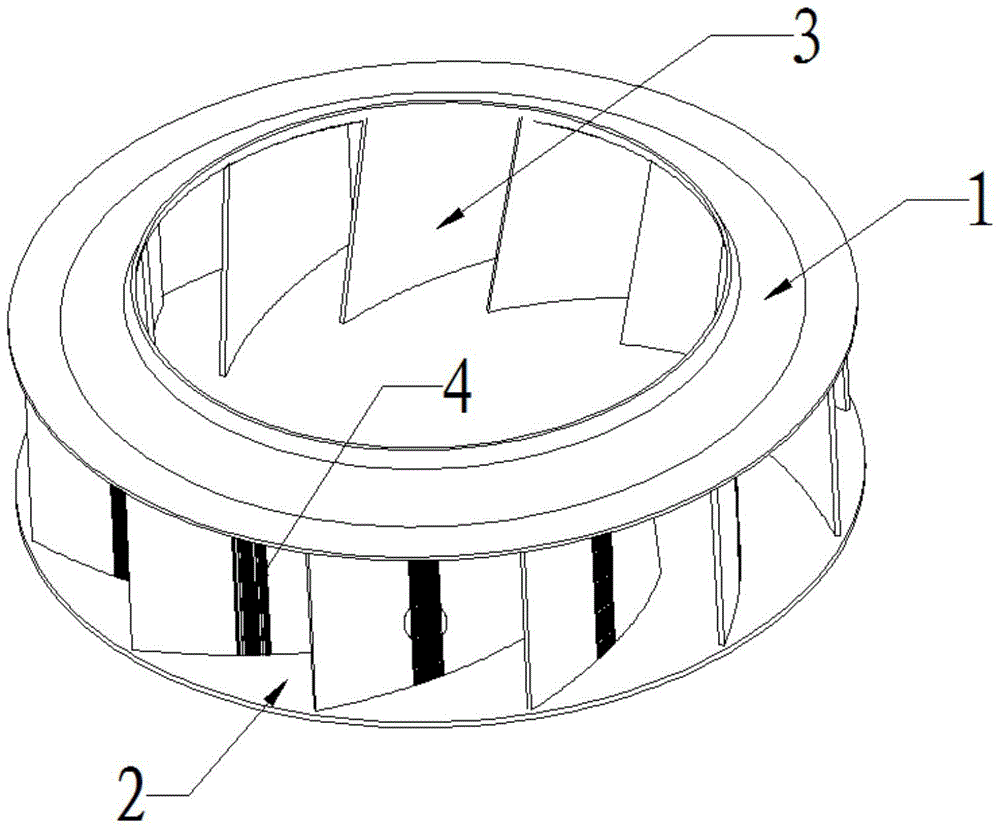

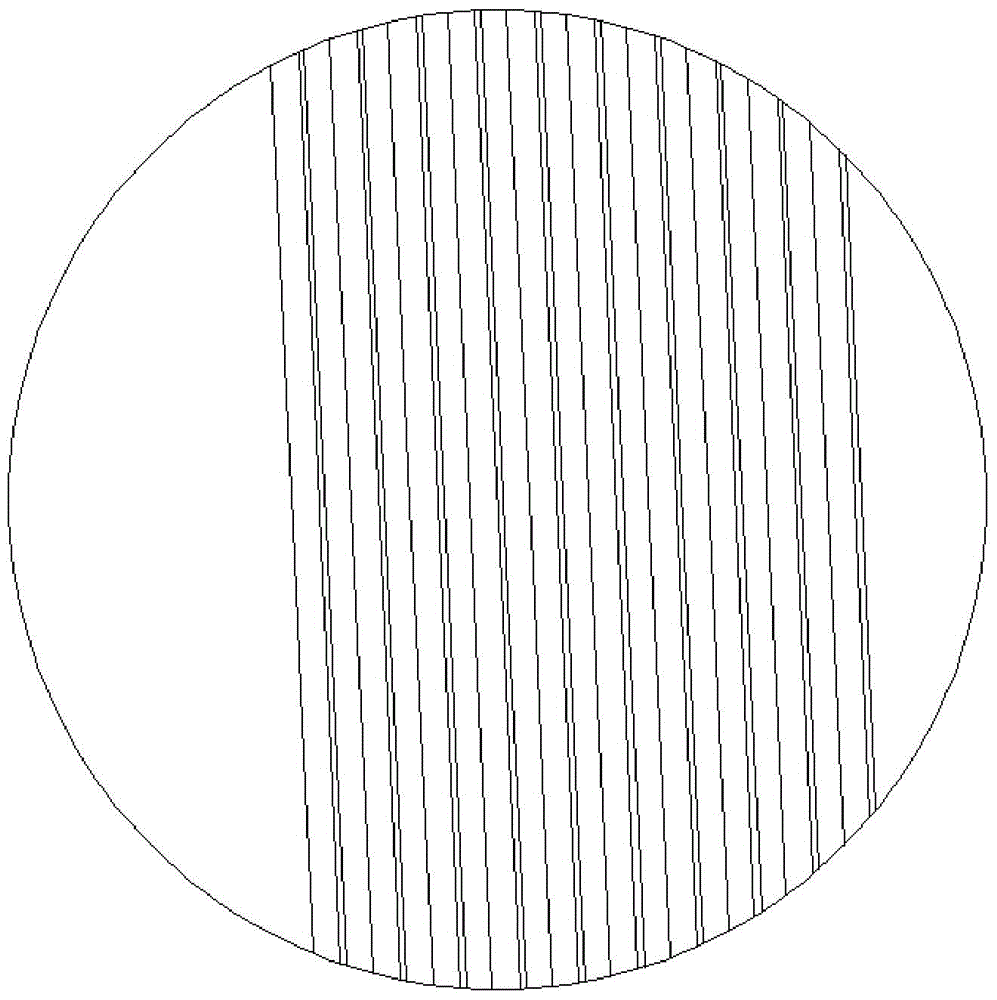

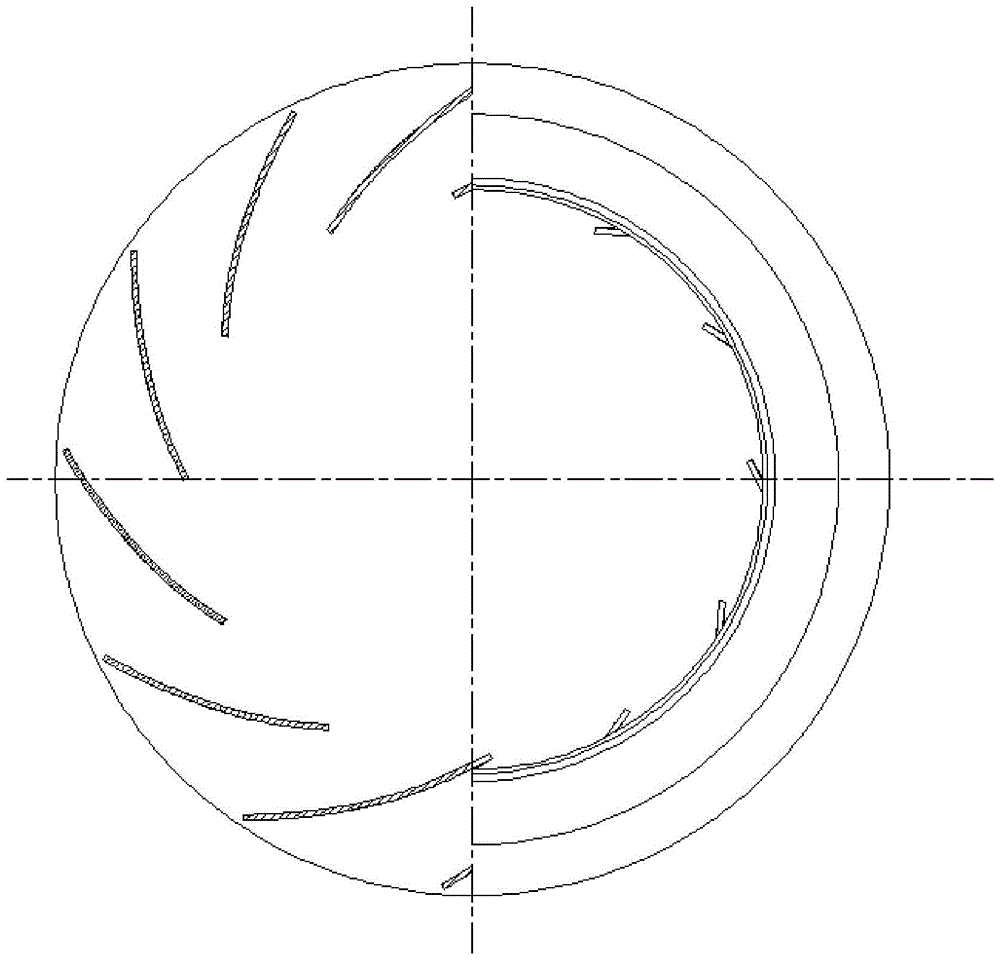

[0019] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, a novel volute-less centrifugal fan with a drag reducing groove includes a wheel cover 1, a disk 2, blades 3, and a drag reducing groove 4, and the axial section of the disk 1 is arc-shaped and conical The combination of cold press forming, the place where the arc and the cone meet is tangent; the disc 2 is in the shape of a disc, and a flange structure is arranged in the middle for installing the motor shaft; the section of the blade 3 is a straight curve , the place in contact with the wheel cover conforms to the profile of the wheel cover, wherein the chord length of the cross-section blade in contact with the wheel cover is shorter than the chord length of the cross-section blade in contact with the wheel disc; the drag reducing groove 4 is a rectangular structure, along the blade inlet to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com