Gas pipeline drag reducer and preparation thereof

A gas pipeline and drag reducing agent technology, applied in the field of polymer compound compositions and pipeline systems, can solve the problems of limited drag reduction effect, etc., and achieve the effects of low equipment requirements, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. This example is a test method in a laboratory. Specifically, 20 parts of hexadecanoic acid are added into a four-necked flask, and 10 parts of diethylenetriamine are injected after heating and melting. Under nitrogen protection, the temperature was slowly raised to 140°C. Then the temperature was programmed slowly, from 140°C to 220°C within 4 hours. Then connect the vacuum pump, evacuate for 3 hours, and the vacuum degree is 20mmHg. The resulting crude product is recrystallized from ethanol to obtain the product.

Embodiment 2

[0025] Embodiment 2. 36 parts of long-chain acids are added into a four-necked flask, and 20 parts of enamines are injected after heating and melting. Under nitrogen protection, the temperature was slowly raised to 140°C. Subsequently, the temperature was programmed slowly according to the above-mentioned heating method, and the temperature was programmed from 140°C to 210°C within 5 hours. Then connect the vacuum pump and vacuumize for 2 hours. The vacuum degree is 25mmHg. The resulting crude product is recrystallized from ethanol to obtain the product.

Embodiment 3

[0026] Embodiment 3. 54 parts of long-chain acids are added into a four-necked flask, and 30 parts of diethylenetriamine are injected after heating and melting. Under nitrogen protection, the temperature was slowly raised to 140°C. Subsequently, the temperature was programmed slowly according to the above-mentioned heating method, from 140° C. to 215° C. within 5 hours. Then connect the vacuum pump and vacuumize for 3 hours. The vacuum degree is 20mmHg. The resulting crude product is recrystallized from ethanol to obtain the product.

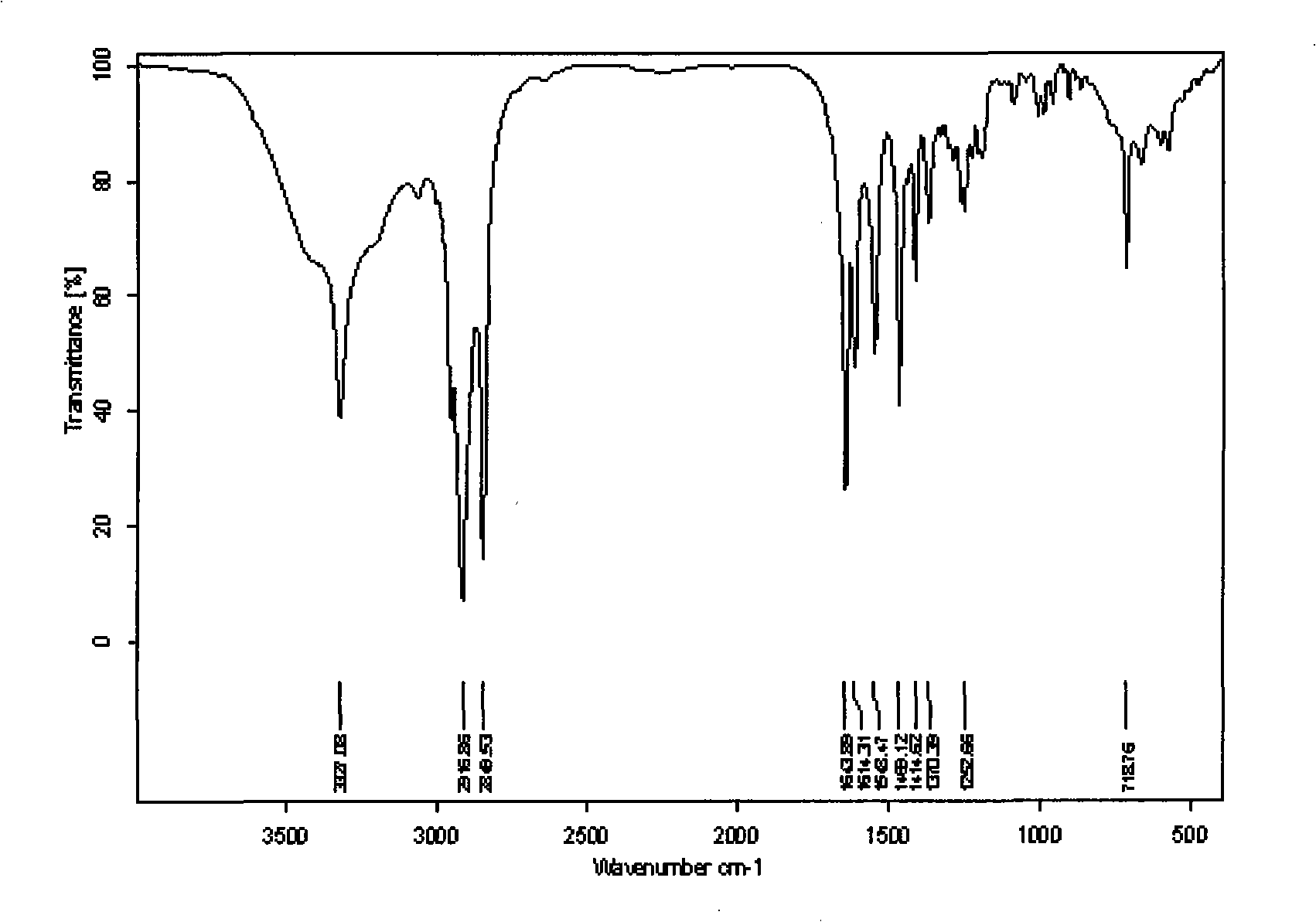

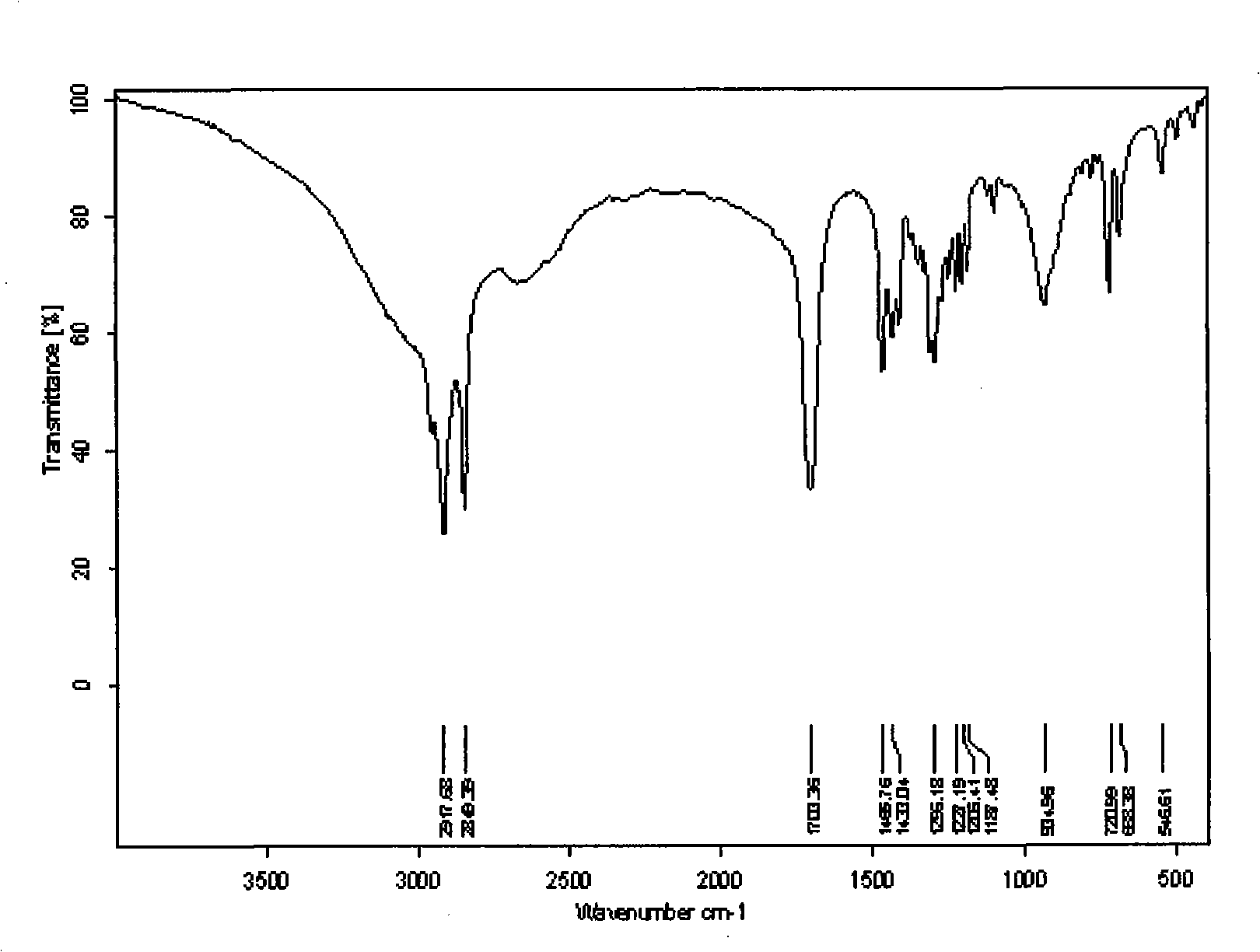

[0027] Above-mentioned three example gained drag reducers are done infrared spectrum analysis through laboratory, figure 1 In the infrared spectrum of the synthesized product, 2916.86cm -1 It is the C-H asymmetric stretching vibration in methylene, 2849.53cm -1 It is C-H symmetrical stretching vibration, and the in-plane rocking vibration of -CH2- in multi-carbon linear alkanes is at 718.16cm -1 There is absorption nearby, 1469.12cm -1 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com