Heavy oil separation method

A separation method, heavy oil technology, applied in the direction of only multi-stage series refining process, etc., can solve the problems of reduced solubility, long extraction time, poor extraction and separation effect, etc., and achieve the effect of preventing entrainment and increasing separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

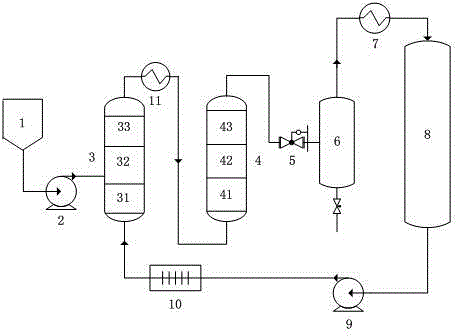

Embodiment 1

[0024] Send 1000g of Iranian residue-reducing feedstock oil into the primary extraction tower, use n-pentane and n-butane as the solvent in a 1:1 mixture, and the extraction temperature ranges of the primary extraction tower are 31, 32, and 33. 210°C, 220°C, the extraction temperature range of the secondary extraction tower 41, 42, and 43 temperatures are divided into: 160°C, 170°C, 180°C, and the volume space velocity of the mixed solvent is 6h -1 , the initial stable pressure of extraction is 3.9MPa, and the pressure is increased linearly to 12 MPa, and the pressure increase rate is 1.0 MPa / h r , taking 10% as the narrow fraction cut point, Iran can be cut into 7 narrow fractions and one residue.

Embodiment 2

[0031] Send 1000g of Luolian residue reduction raw material oil into the extraction kettle, use n-pentane and n-butane as the solvent in a 1:1 mixture, and the extraction temperature range of the first-stage extraction tower is 31, 32, and 33. The temperature is divided into: 200°C, 210°C ℃, 220℃, and the extraction temperature range of the secondary extraction tower 41, 42, 43. The temperature is divided into: 160℃, 170℃, 180℃, and the solvent space velocity is 6h -1 , the extraction initial stable pressure is 3.9MPa, linearly increase the pressure to 12MPa, and the pressure increase rate is 1.0 MPa / h r , with 5% as the narrow fraction cut point, Iran can be cut into 12 narrow fractions and one residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com