Doping method

A light doping and heavy doping technology, applied in the field of doping, can solve the problems of large performance differences of semiconductor devices and relatively large performance differences of semiconductor devices, and achieve the effect of reducing performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

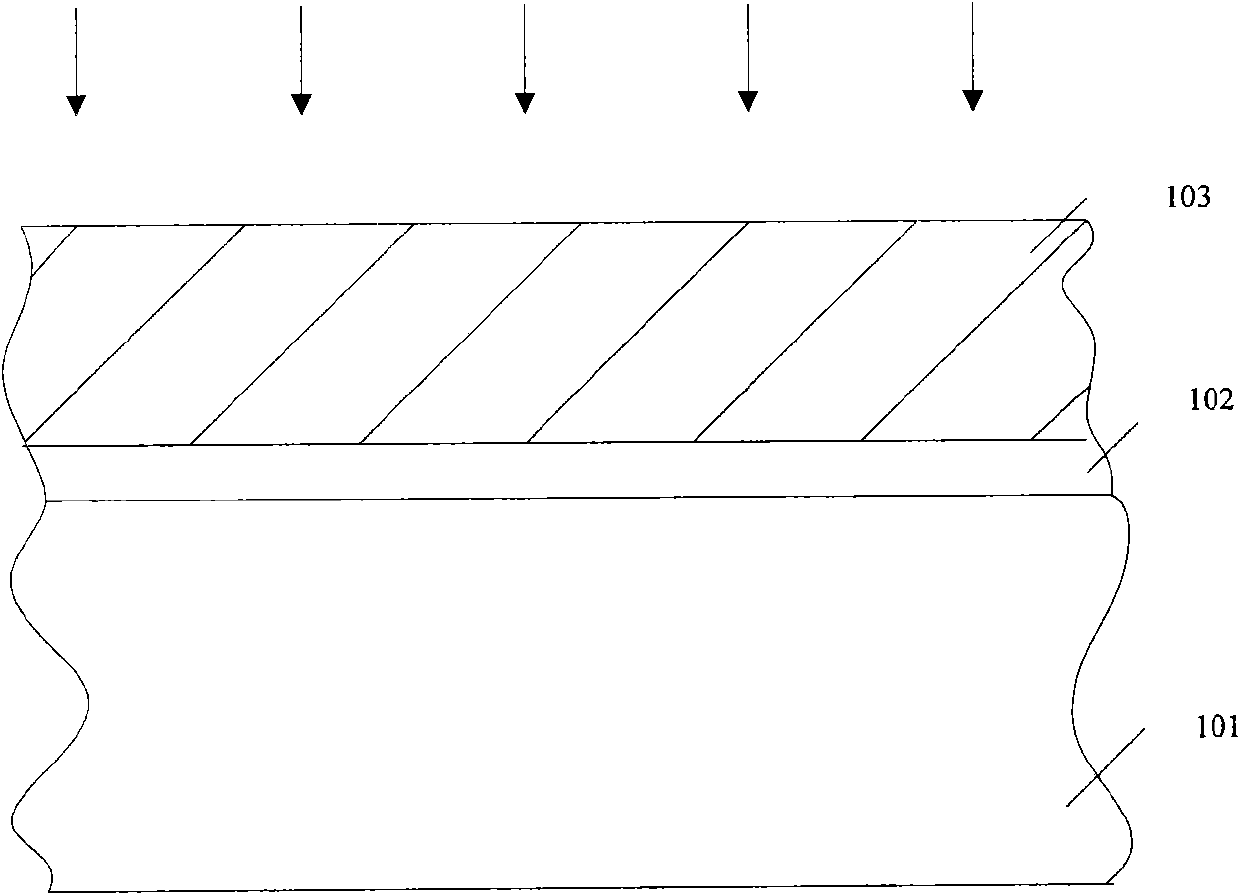

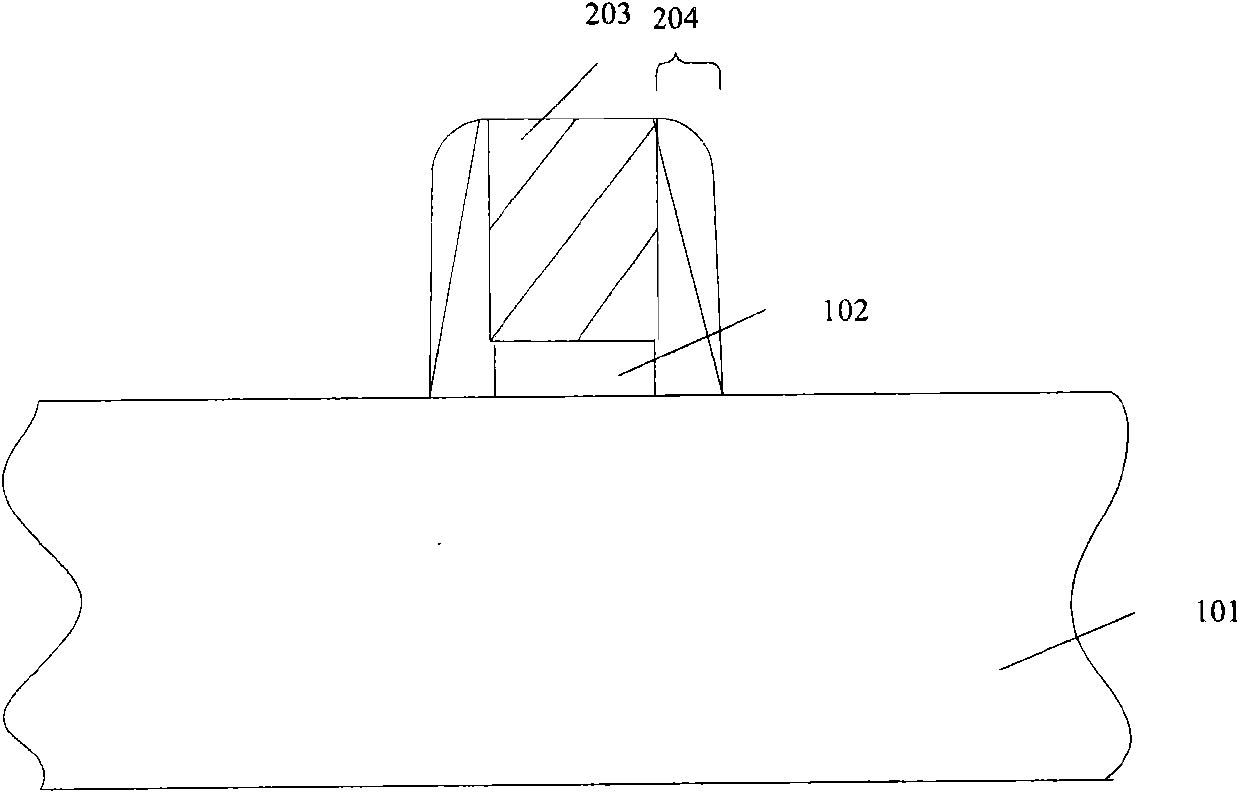

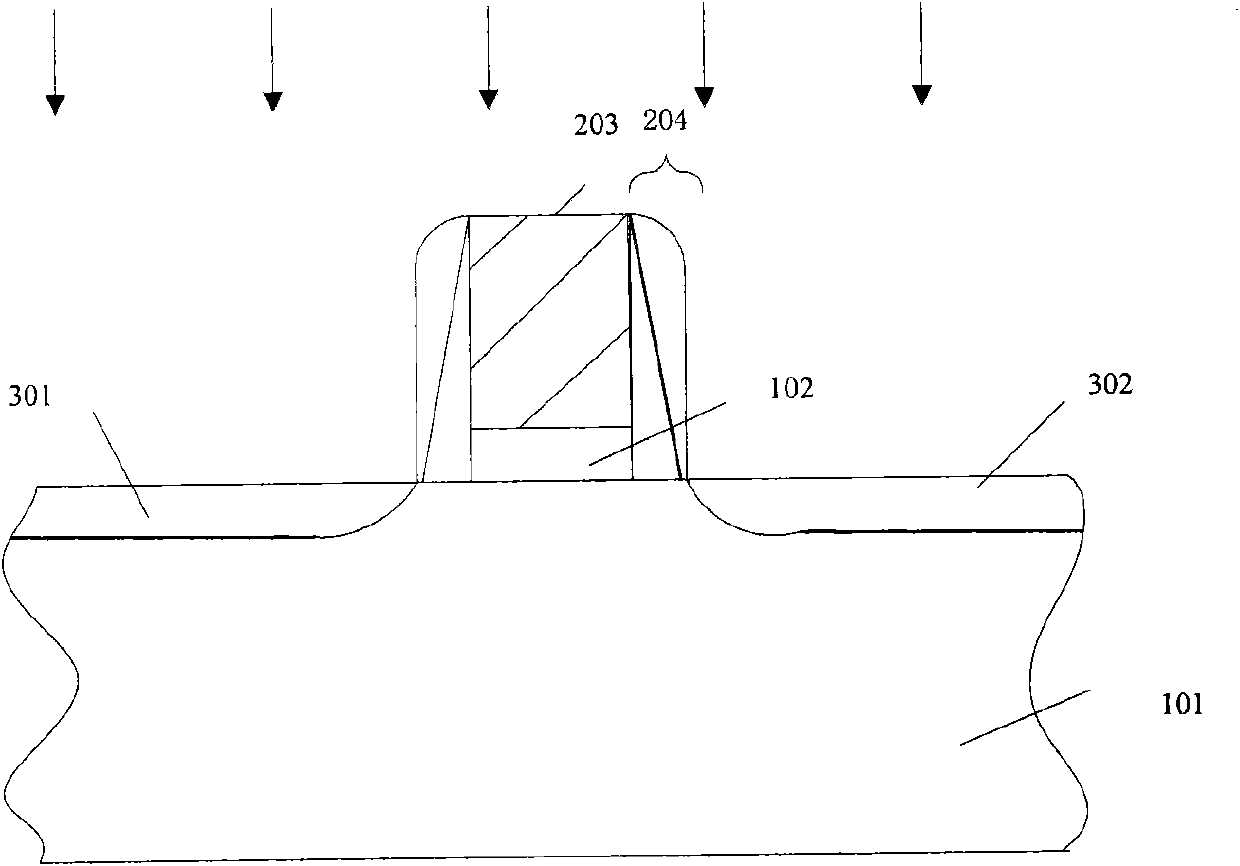

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0039] The core idea of the present invention is: when lightly doping or heavily doping the substrates on both sides of the grid, firstly adjust the angle of the ion beam, and keep a fixed angle between the ion beam and the vertical direction of the substrate surface, Use half of the preset ion implantation dose to lightly or heavily dope the substrates on both sides of the gate, then rotate the wafer 180 degrees in the horizontal direction, and use half of the preset ion implantation dose to do the gate again. Lightly or heavily doped the substrates on both sides of the electrode, and finally form a lightly doped drain and a lightly doped source, or a drain and a source, or first adjust the angle of the ion beam and make the ion beam and The vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com