Method for improving radial structure and performance uniformity of G115 steel large-caliber thick-wall pipe

A thick-walled pipe and large-diameter technology, which is applied to improve the radial structure and performance uniformity of G115 steel large-diameter thick-walled pipes, and in the field of pipe manufacturing related to supercritical thermal power units with steam parameters of 630-650°C, can solve the problem of radial structure and performance. Uneven performance and other problems, to achieve good radial organization and performance uniformity, improve the radial temperature field, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

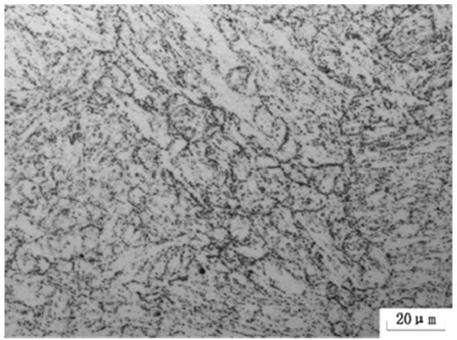

[0034] The main components of the novel martensitic heat-resistant steel (G115) in the embodiment of the present invention are (wt.%): C: 0.080%; Cr: 8.99%; Si: 0.30%; Mn: 0.50%; Co: 3.01%; W: 2.81%; V: 0.21%; Nb: 0.53%; N: 0.008%; B: 0.014%; Cu: 0.8%; Ti: 0.01%; Zr: 0.01%; the balance is Fe.

[0035] The present invention smelts 40 tons of molten steel according to the above-mentioned composition EAF+LF+VD process, casts 3 steel ingots, and selects two of them for vertical hot extrusion. Large-diameter thick-walled heat-resistant steel pipe. One is implemented by the prior art; the other is implemented by the process of the present invention.

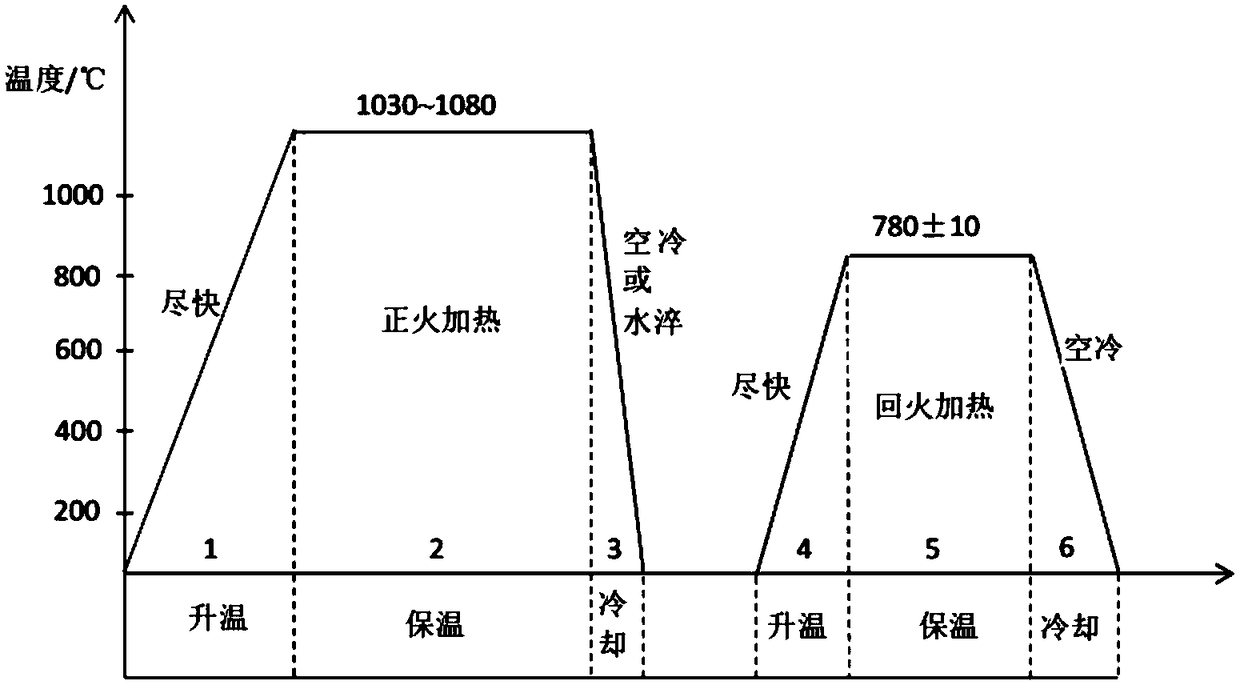

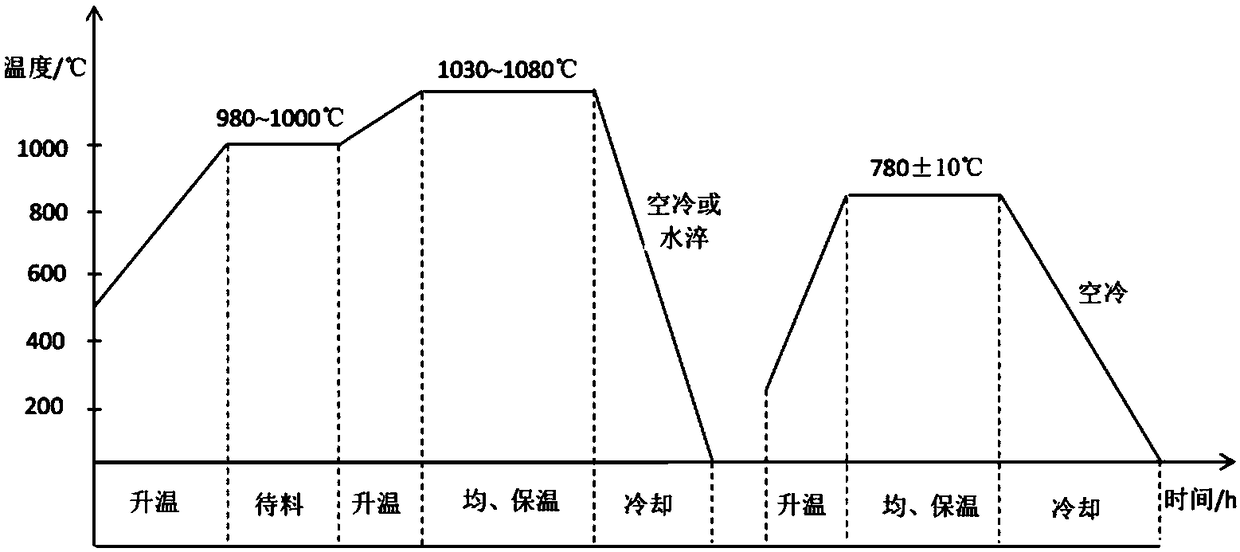

[0036] The implementation of the existing technology is as follows: the temperature of the furnace is 550 ° C, and after the penetration is heated to 1080 ° C at 130 ° C / h, the penetration time is 2 hours, and then the temperature is kept for 1 hour, and the water is quickly quenched to room temperature after the furnace; Fire tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com