A heat treatment method for preventing abnormal grain growth of heat-resistant alloy thick-walled tubes

A technology of abnormal grain growth and heat treatment method, which is applied in the field of heat treatment to prevent abnormal grain growth of heat-resistant alloy thick-walled tube, can solve the problem of few reports on heat treatment, and achieve the improvement of radial temperature field, radial structure and heat treatment. Good uniformity of properties and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

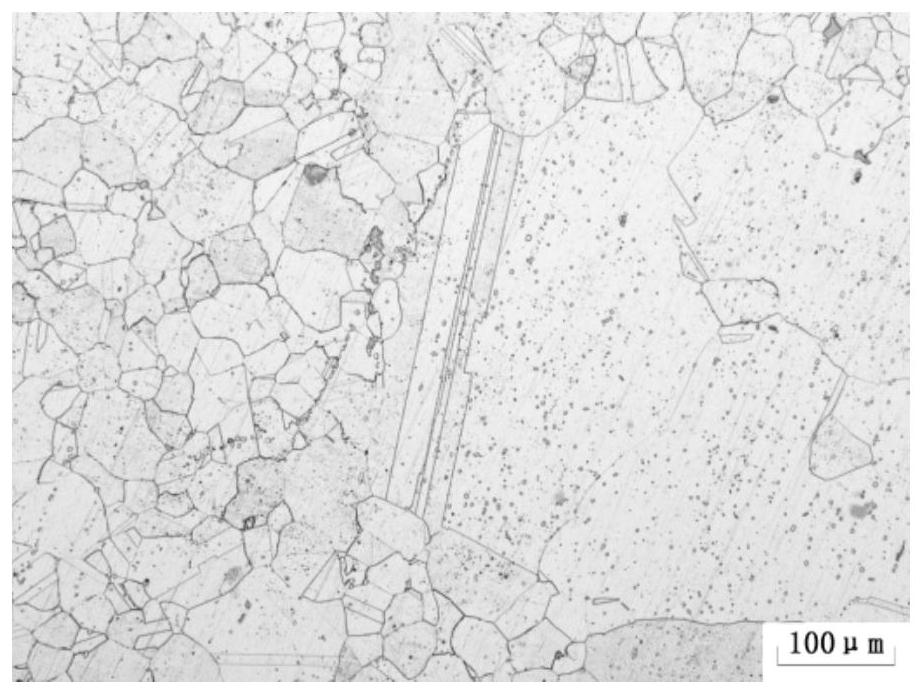

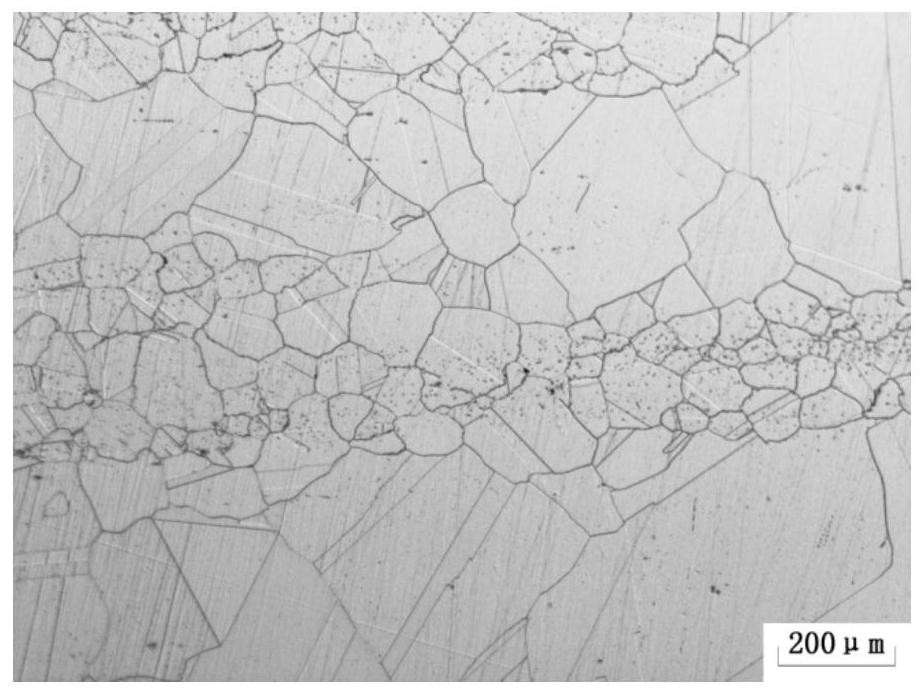

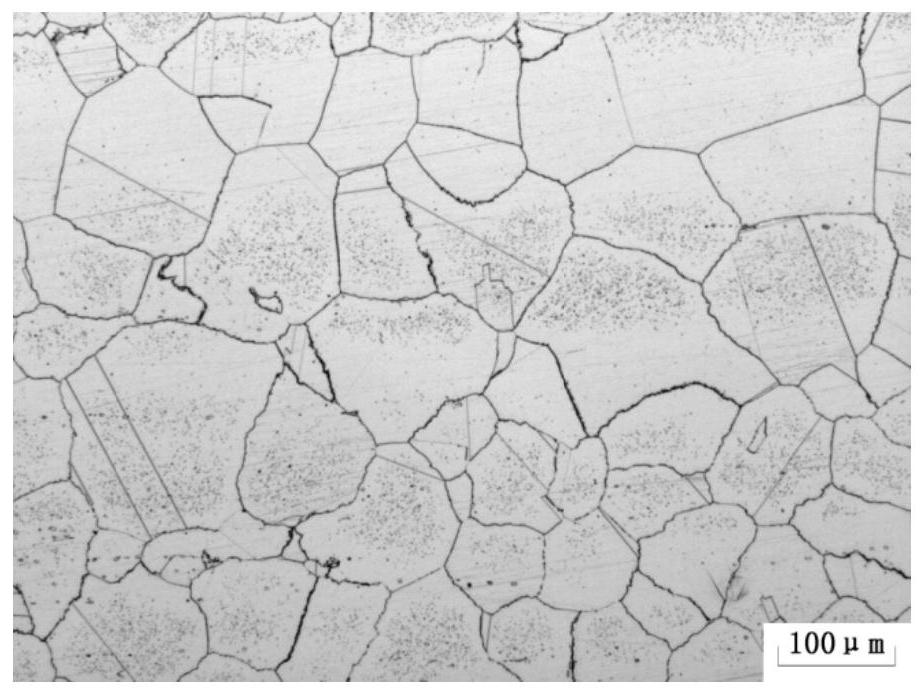

Image

Examples

Embodiment 1

[0022] Example of the present invention C-HRA- The main components of the heat-resistant alloy are (wt.%): Cr 22.0%; C0.06%; Mn 0.3%; Co 12.0%; Mo 8.8%; Ti 0.5%; Al 1.0%; W 0.1%; B 0.0035% ; Zr0.03%; Nb 0.1%; P 0.006%; S 0.001%; Mg 0.005; Nickel is the balance and an inevitable impurity element.

[0023] The invention smelts 2 6-ton alloy ingots according to the above-mentioned composition VIM+ESR process, and uses a vertical hot extruder to extrude the pipes. The product specifications are large-diameter thick-walled heat-resistant steel pipes with an outer diameter of Φ559mm × a wall thickness of 120mm. One is implemented according to the existing technology; the other is implemented according to the process of the present invention.

[0024] The existing technology is implemented as follows: the furnace is installed at a temperature of 300°C, heated to 1170°C at a rate of 70-100°C / h after the pass-through insulation, and kept for 1 hour after the pass-through insulation, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com