Array substrate, manufacturing method of array substrate and display device

An array substrate and substrate technology, applied in the field of display devices, can solve problems such as the decrease of electron mobility of thin film transistors and affect the performance of thin film transistors, and achieve the effect of reducing performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

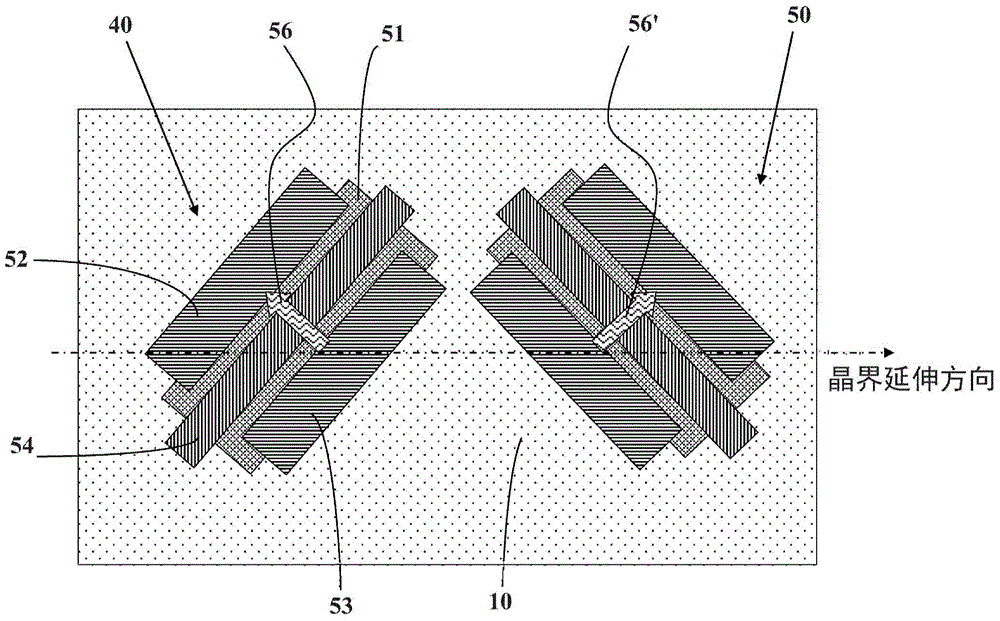

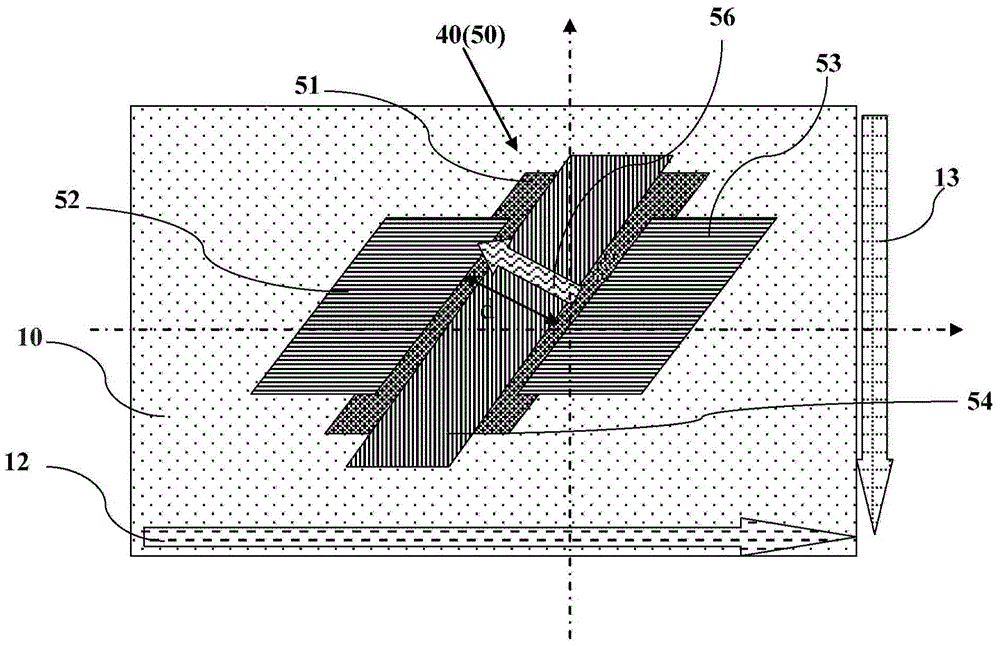

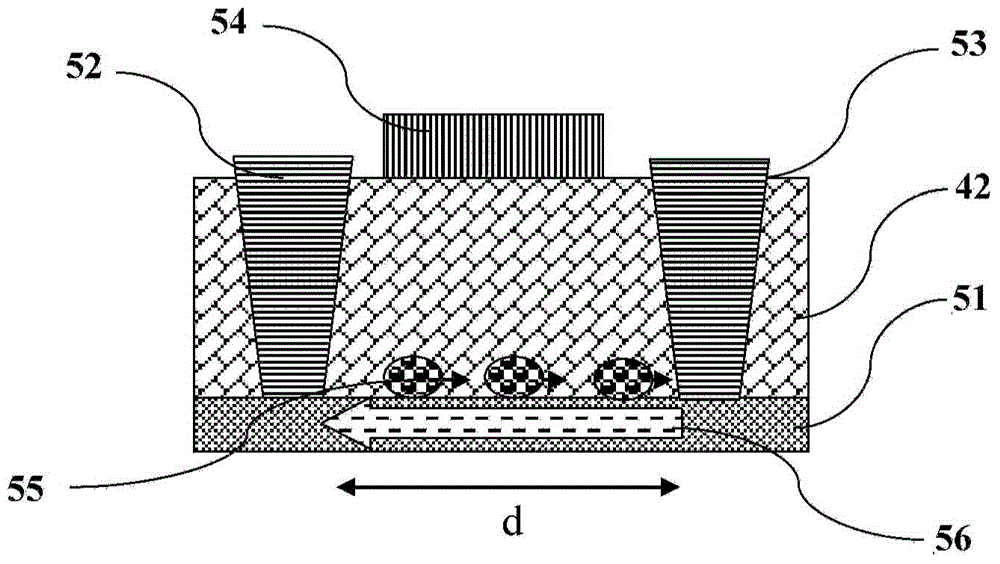

[0035] According to the general inventive concept of various exemplary embodiments of the present invention, there is provided an array substrate including: a substrate; a polysilicon thin film including a plurality of grain boundaries extending in the same direction; and at least one channel A thin film transistor whose current direction is the first direction, and at least one thin film transistor whose channel current direction is the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com