Flow sharing device and method of battery energy storage liquid cooling system

A battery energy storage and liquid cooling technology, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of different flow rates of coolant, unsatisfactory temperature uniformity effect of parallel systems, and unequal inlet head pressure, etc., to achieve Improved standardization, simple and easy implementation process, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

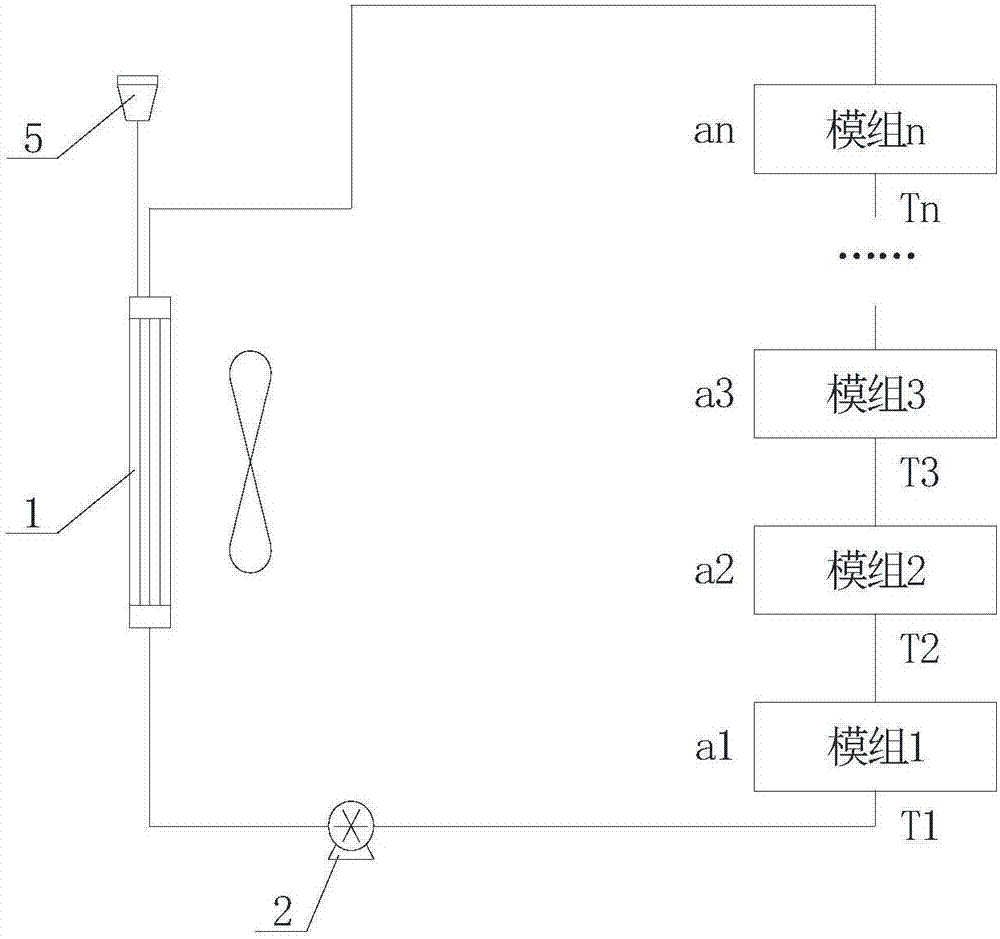

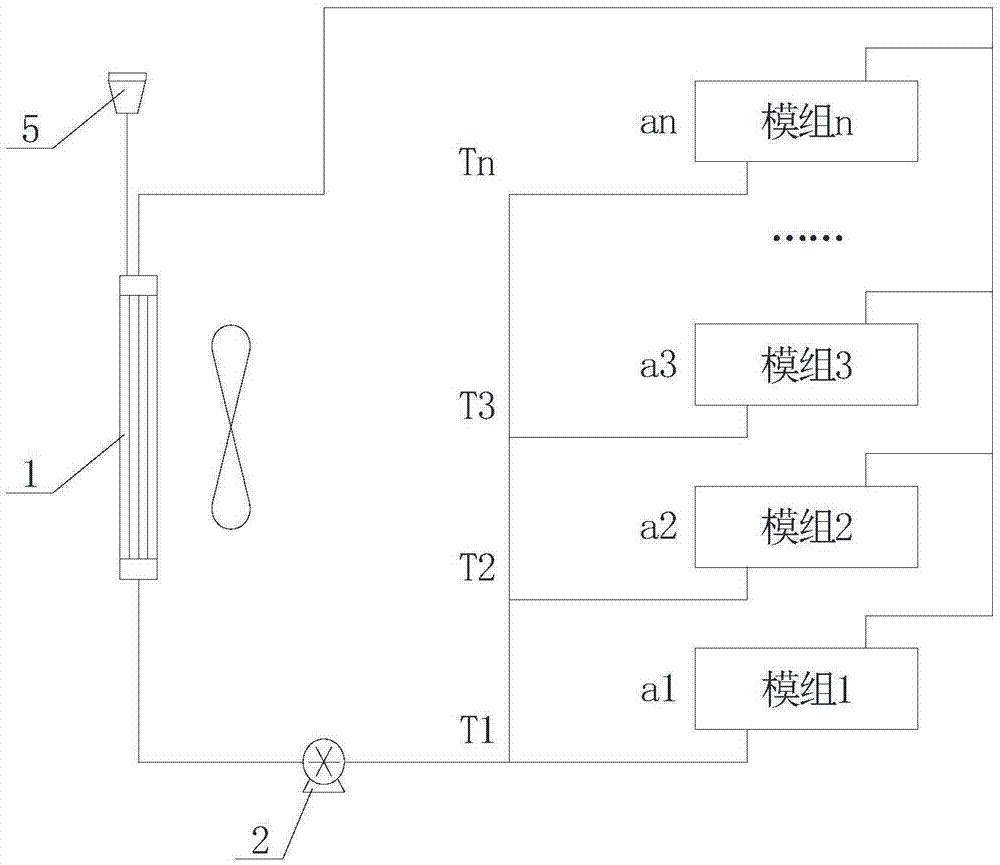

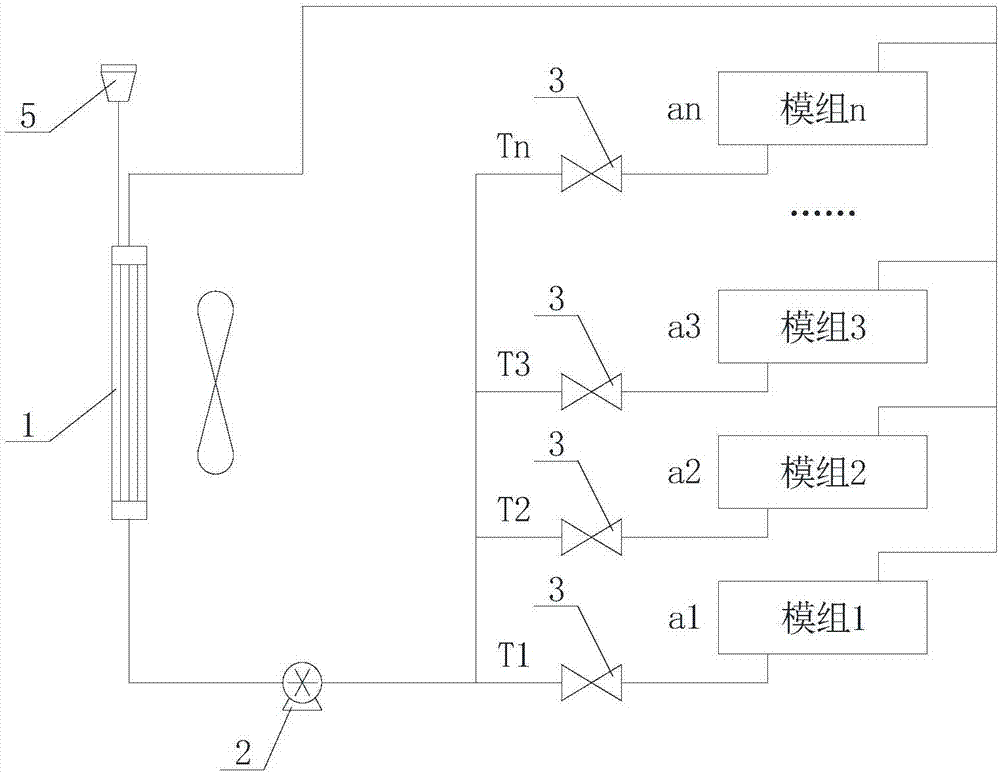

[0047] Such as image 3 , Figure 4 , Figure 5 Shown is Embodiment 1 of the present invention. In this embodiment, a battery energy storage liquid cooling system current sharing device includes several sets of battery modules arranged side by side, namely module 1, module 2, module 3, ..., module n, each group of battery modules is connected to a liquid cooling system, and is provided with a cooling liquid input port 4, a throttle tube 3 is provided in the input port 4, and a throttle hole 3 is provided on the throttle tube 3- 1. Adjust the coolant entering the input port 4 to equal pressure through the throttling tube 3.

[0048] When the coolant pressure is equal, the coolant flow rate and flow rate will tend to be equal, the convective heat transfer coefficient α will tend to be equal, and the convective heat transfer rate Φ will tend to be equal.

[0049] In this embodiment, the inlet 4 and the cooling liquid pipeline are made separately; the throttle tube 3 and the in...

Embodiment 2

[0062] Embodiment 2 of the present invention is an improvement made on the basis of Embodiment 1. The difference between Embodiment 2 of the present invention and Embodiment 1 is that the throttling tube 3 is provided with a latch or a slot, and on the inner wall of the input port 4 A card slot or a card shoot is provided, and the throttle tube 3 and the input port 4 are assembled together by card connection.

[0063] After the throttling tube 3 is inserted into the input port 4, the two can be assembled together by welding or bonding.

[0064] Welding or bonding can be used as an auxiliary means of strengthening the connection technology, or welding or bonding can be used alone.

[0065] Other contents of Embodiment 2 of the present invention are the same as Embodiment 1, and will not be described again here.

Embodiment 3

[0067] Embodiment 3 of the present invention is an improvement made on the basis of Embodiment 1. The difference between Embodiment 3 of the present invention and Embodiment 1 is that the inlet 4 and the cooling liquid pipeline are integrally made, and the throttle tube 3 and the inlet 4 made in one piece.

[0068] If the inlet port 4 and the coolant pipeline are integrally formed, it is better to make the throttle tube 3 and the inlet port 4 integrally at the same time, so as to save the trouble of installing the throttle tube 3 later.

[0069] If the throttling tube 3 and the input port 4 are made integrally, then the input port 4 and the cooling liquid pipeline can also be made separately, because it is still very convenient to install the input port 4 in the later stage.

[0070] In Embodiment 1, different types of throttling tubes 3 need to be selected, and in this embodiment, different types of input ports 4 or different types of liquid cooling system pipes need to be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com