Regenerated concrete block material and production method thereof

A technology of recycled concrete and production methods, applied in cement production, sustainable waste treatment, solid waste management, etc., can solve the problems of low efficiency of resource utilization of construction waste, achieve high environmental and economic benefits, and improve the utilization rate of resources , highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

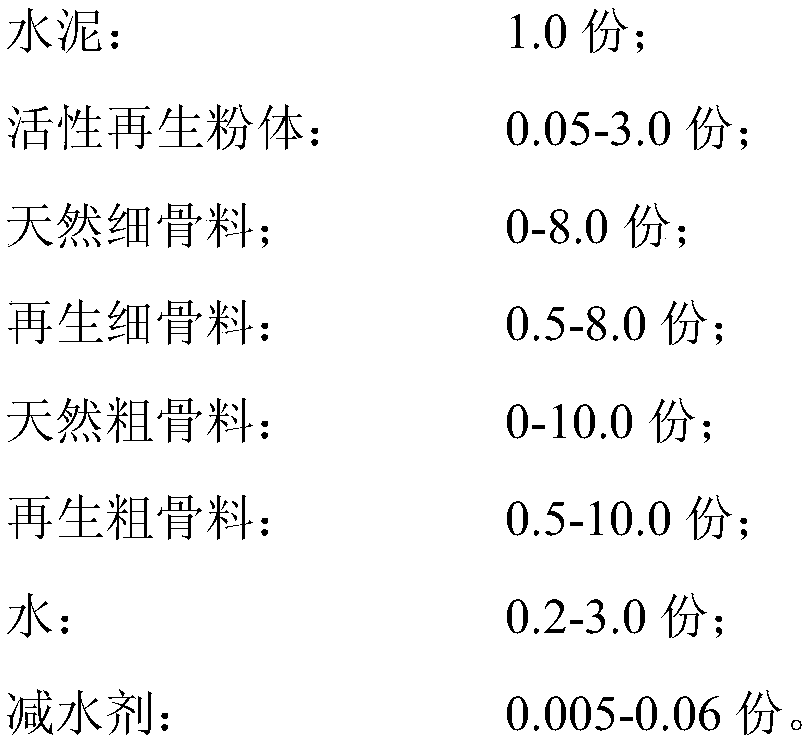

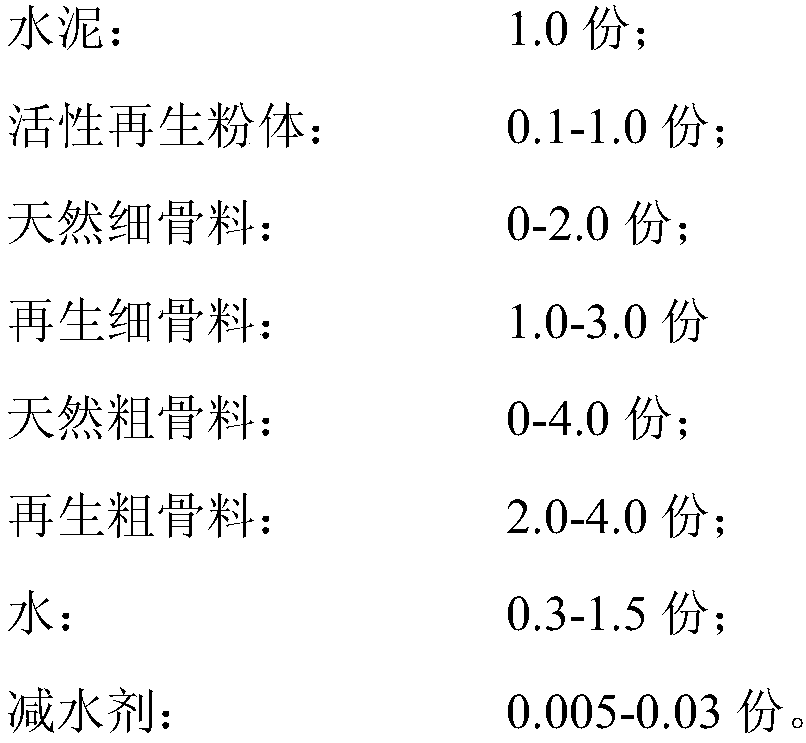

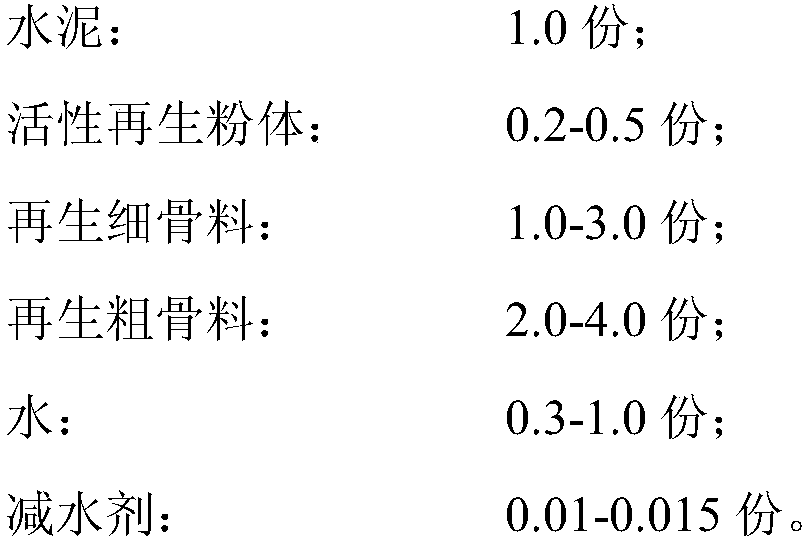

[0096] Embodiment 1-3 and comparative example 1

[0097] According to the formula ratio, accurately weigh cement, active recycled powder, recycled fine aggregate, and recycled coarse aggregate and put them into a horizontal forced mixer for uniform mixing. Dry mix the above dry materials for 2 minutes, then add water and reduce water. Stirring was continued for 2 min after the preparation to obtain a mixture. Among them, according to the particle size of the active recycled powder, the amount of water reducer is additionally increased; the recycled fine aggregate and recycled coarse aggregate are subjected to surface saturation and surface drying treatment before mixing.

[0098] Then, the mixture is poured, molded by mechanical pressure, demolded, and cured to obtain the required recycled concrete blocks. Wherein, the conservation is selected from one or a combination of natural conservation or water spray conservation. Finally, recycled concrete blocks are obtained, with t...

Embodiment 4-6

[0102] According to the formula ratio, accurately weigh cement, active recycled powder, natural fine aggregate, recycled fine aggregate, recycled coarse aggregate, and natural coarse aggregate and put them into a horizontal forced mixer for uniform mixing. Stir for 2 minutes, then add water and water reducing agent and continue to mix for 2 minutes to obtain a mixture. Among them, according to the particle size of the active recycled powder, the amount of water reducer is additionally increased; the recycled fine aggregate and recycled coarse aggregate are subjected to surface saturation and surface drying treatment before mixing.

[0103] Then, the mixture is poured, molded by mechanical pressure, demolded, and cured to obtain the required recycled concrete blocks. Wherein, the conservation is selected from one or a combination of natural conservation or water spray conservation. Finally, recycled concrete blocks are obtained, with three types of specimens of 100mm*100mm*100...

Embodiment 7

[0106] Example 7 - Compressive Strength Properties of Recycled Concrete

[0107] The compressive strength of the samples obtained in the above-mentioned Examples 1-3 and Comparative Example 1 was measured, and the specific results are shown in Table 4. Table 4 shows the measured values of compressive strength of concrete under different active regeneration powder mixing rates and different curing ages. It can be seen from the data in Table 4 that when the water-binder ratio is 0.40, the compressive strength of concrete decreases with the increase of the replacement rate of active recycled powder, but when the replacement rate of active recycled powder is 15%-30%, the strength decreases Not obvious; when the water-binder ratio is 0.50 and the curing age is 56d, the strength of Example 1 with an active regeneration powder replacement rate of 15% is slightly higher than that of Comparative Example 1, and the active regeneration powder replacement rate The intensity of Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com