Perforated plate connector with shoe-shaped slotted holes, steel beam and method

A technology of perforated plate connectors and connectors, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of inconvenient interspersed arrangement of steel bars and increased manpower input, so as to save production and installation costs, improve construction efficiency, The effect of accurate placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

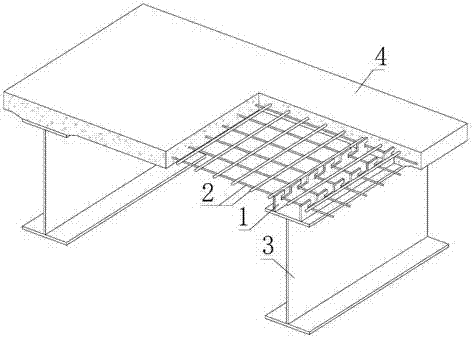

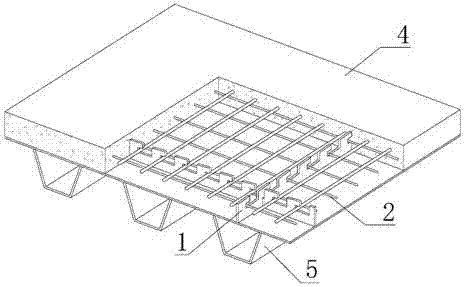

[0034] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

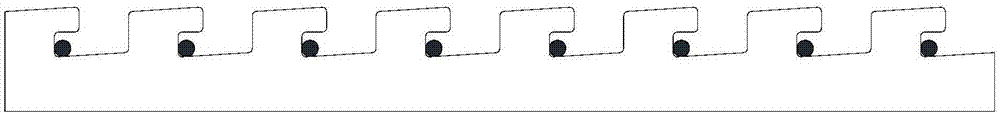

[0035] Such as figure 1 As shown in the figure, a perforated plate shear connector with a shoe-shaped groove, one side of the shear connector 1 has a straight profile, and the other side of the shear connector 1 is repeatedly arranged with convex connectors and recessed joints. Slot hole, the concave slot hole presents a shoe shape; the shape of the protruding connector is consistent with the shape of the concave slot hole after being rotated 180°, and the size is the same, that is, two connectors of the same size, one of which can be connected After rotating 180°, it is docked with another tooth groove, and is completely snapped together, so a steel plate of an appropriate size can cut two shear connectors of this type without redundant materials.

[0036] The bottom of the shoe-shaped slot of the shear connector 1 has a slope, and the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com