Construction method of double-shaft horizontal docking salt cavern storage

A construction method and shaft technology, which are used in earth-moving drilling, mining equipment, mining devices, etc., can solve the problems of slow cavity-making rate, complicated cavity-making process, and large waste of resources in a single well, so as to solve the problem of water-soluble cavity making. The effect of shape control is difficult, the layout process is simplified, and the construction speed is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

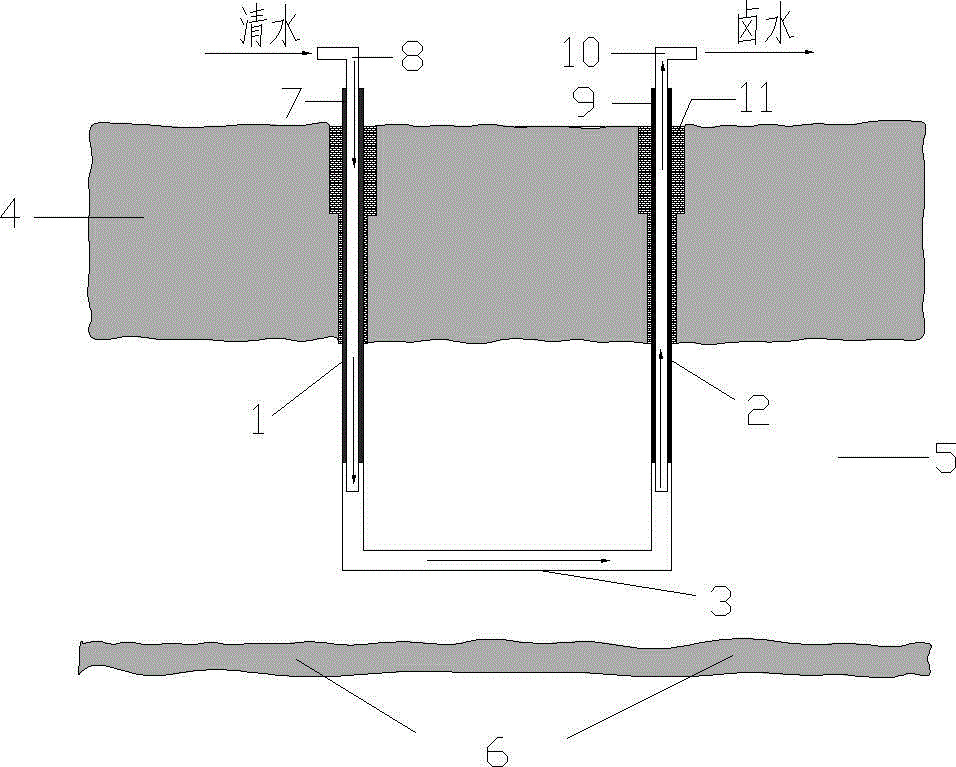

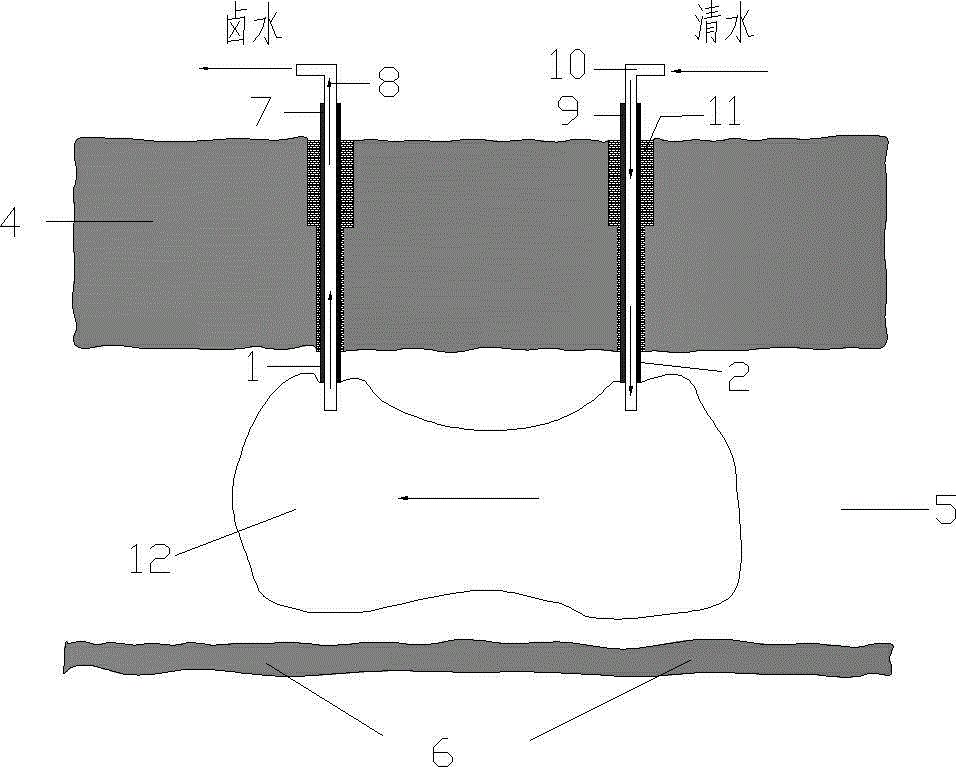

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] A method for constructing a double-shaft horizontally connected salt cavern storage, the method includes the following steps:

[0022] 1), see figure 1 : Select the excavation point a and the excavation point b of two shafts respectively on the mine roof 4 of the salt rock mine layer 5 to be excavated, to ensure that the thickness of the salt rock mine layer 5 between the two shafts is not much different, in order to build a stable In general, the distance between the wellheads of the two shafts is 10-30m, so that the two shafts can be connected in the early stage of cavity construction, and it is convenient to control the shape of the cavity in the later stage; after selecting excavation point a and excavation point b, At the excavation point a and the excavation point b, excavate to the target salt rock layer 5 by means of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com