Reinforced concrete prefabricated road slab and installation and construction method thereof

A technology of reinforced concrete and construction method, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of large dust on dry roads, noise, dust and construction waste, watering and dust reduction, labor and water, etc. Good integrity, reduce engineering costs, and reduce the effect of wet work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

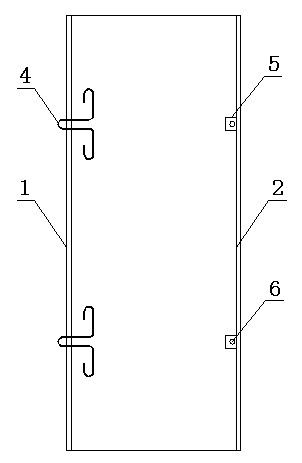

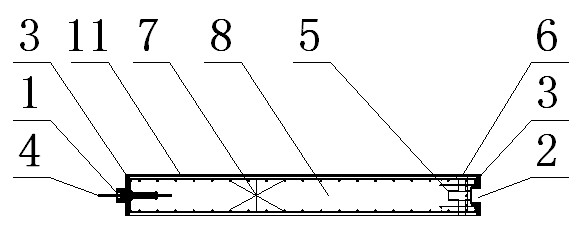

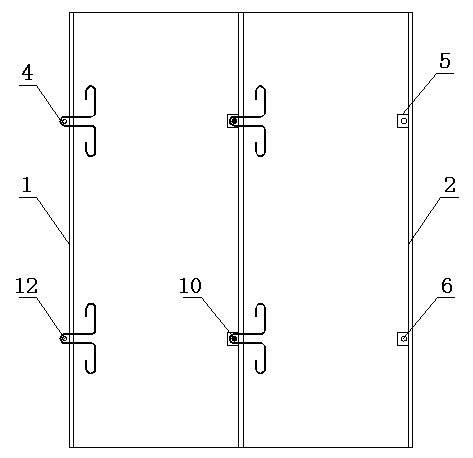

[0013] From Figure 1 ~ Figure 4 It can be seen from the figure that: a reinforced concrete prefabricated road slab and its installation and construction method are characterized in that the reinforced concrete prefabricated road slab is made into a tongue-and-groove slab ( figure 1 ), with a plate thickness of 220mm, a male groove 1 is set in the middle part of the left plate thickness, and a female groove 2 is set in the middle part of the right plate thickness. The width of the male groove is smaller than the width of the female groove. Two full-length angle steels 3 are provided for protection at the joints of the groove and the groove and groove, and a steel pull ring 4 is respectively installed in the middle part of the plate thickness at the upper and lower 1 / 4 spans of the length of the groove on the left side. Grooves 5 are provided in the middle of the plate thickness corresponding to the two steel bar pull rings 4, and a steel sleeve 6 perpendicular to the plate sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com