Method and device for efficiently bleaching medium-concentration paper pulp through cooperation of ozone and chlorine dioxide

A chlorine dioxide and ozone technology, applied in pulp bleaching, textile and papermaking, cellulose pulp post-treatment, etc., can solve the problems of high cost, dependence, and low pulp strength, reduce pollution load, and upgrade easily Efficient and synergistic bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

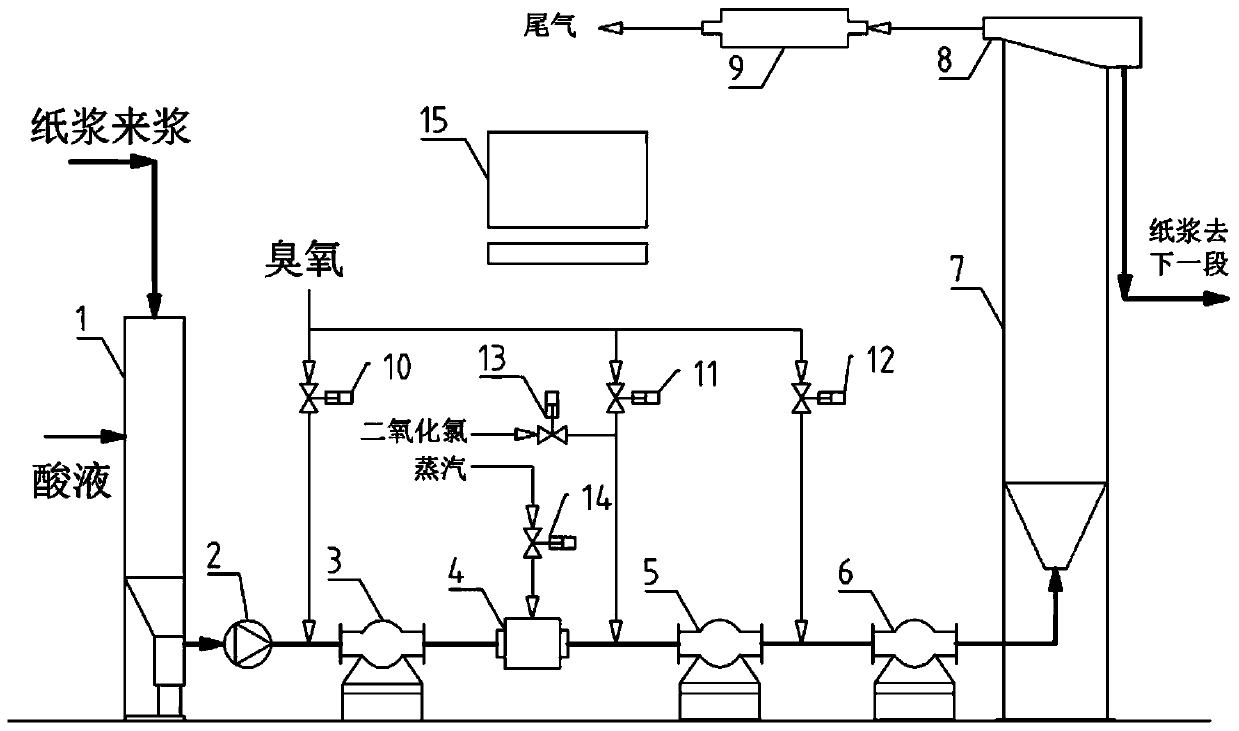

[0080] Ozone and chlorine dioxide bleaching process:

[0081] (1) The slurry in the previous section enters the medium consistency standpipe 1, adding dilution water to adjust the quality pulp concentration to 12%, adding a certain amount of acid solution to adjust the pH to 3, and turning on the medium consistency pump 2 to transport the pulp.

[0082] (2) Ozone addition: open the first air inlet valve 10 to press in the ozone with an amount of 0.6%, and open the pre-mixer 3 to make the ozone and the slurry mix and react.

[0083] (3) Open the steam inlet valve 14 to add steam, and the steam and the slurry are mixed in the steam mixer 4 and heated to 60°C.

[0084] (4) Chlorine dioxide addition: open the chlorine dioxide inlet valve 13 to pump chlorine dioxide in an amount of 0.3%, and open the middle mixer 5 to make the chlorine dioxide and the slurry mix and react.

[0085] (5) Supplementary reaction: the slurry mixed with ozone and chlorine dioxide directly enters the ble...

Embodiment 2

[0102] Ozone and chlorine dioxide bleaching process:

[0103] (1) The slurry from the previous section enters the medium-consistency riser 1, adding dilution water to adjust the mass pulp concentration to 12%, adding a certain amount of acid solution to adjust the pH to 2, and turning on the medium-consistency pump 2 to transport the pulp.

[0104] (2) Ozone addition: open the first air inlet valve 10 to press in the ozone with an amount of 0.4%, and open the pre-mixer 3 to make the ozone and the slurry mix and react.

[0105] (3) Open the steam inlet valve 14 to add steam, and the steam and the slurry are mixed in the steam mixer 4 and heated to 60°C.

[0106] (4) Chlorine dioxide addition: open the chlorine dioxide inlet valve 13 to pump chlorine dioxide in an amount of 0.5%, and open the middle mixer 5 to make the chlorine dioxide and the slurry mix and react.

[0107] (5) Supplementary reaction: the slurry mixed with ozone and chlorine dioxide directly enters the bleachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com