Wind tunnel test section bottom plate surface temperature uniformity testing device and testing method thereof

A technology of wind tunnel test and surface temperature, which is applied to measuring devices, thermometers, thermometer components, etc., can solve the problems of inability to the temperature of the bottom plate of the wind tunnel and being easily affected by the use environment, so as to achieve outstanding substantive characteristics and increase the temperature. The effect of testing accuracy and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

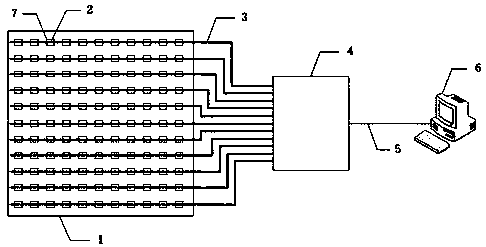

[0032] In this embodiment, the surface temperature uniformity of the bottom plate of a wind tunnel test section is tested. The bottom plate of the test section is made of 304 stainless steel, and its surface temperature ranges from -10°C to +112°C, and the temperature uniformity is required to be better than ±0.5°C.

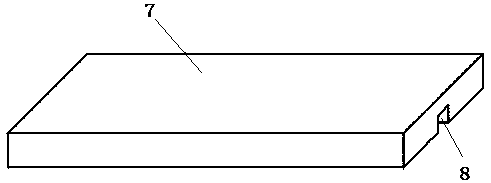

[0033] First, the bottom plate of the wind tunnel test section is evenly divided into 8 bottom plate blocks, each of which has a size of 3000mm×3000mm, and 121 temperature measurement points are preset on the surface of each bottom plate block to form an 11×11 array. The distance between temperature measuring points is 250mm. Then, 11 fibers are prepared, and 11 fiber gratings reflecting different central wavelengths are etched on each fiber, and each fiber grating occupies a different wavelength band with a bandwidth of 2 nm. After all the fiber gratings 2 are etched, 11 fiber grating strings are correspondingly arranged on the temperature measuring points on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com