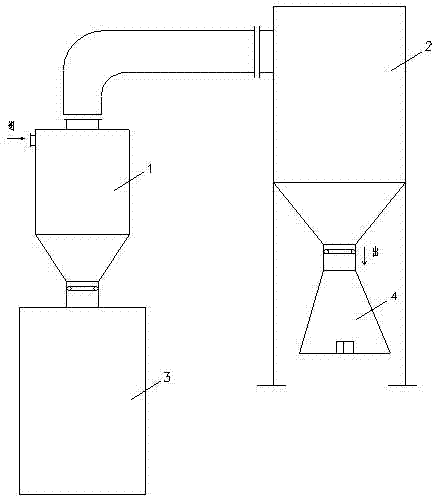

Integral dust removing and separating device

A separation device, an integrated technology, applied in solid separation, separation of solids from solids by air flow, sieves, etc., can solve the problems of large floor space, complex layout, long process, etc., and achieve a small floor space. , The effect of low operating cost and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

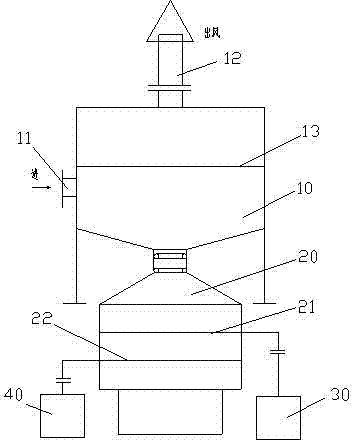

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 2 As shown, it is an integrated dust removal and separation device provided by the present invention, which includes:

[0019] Material receiving sharer 10, the side of the material receiving sharer 10 is provided with a feed inlet 11, the airflow containing material dust is fed from the feed inlet 11 of the material receiving sharer 10, and the top of the material receiving sharer 10 is set There is an air outlet duct 12 through which the wind from the separated dust is discharged;

[0020] The powder sieving machine 20 arranged at the bottom of the material receiving sharer 10 is a rotary vibration sieve, and the first filter screen 21 and the second filter screen 22 are arranged in parallel in the powder sieving machine 20 at intervals from top to bottom, The aperture of the first filter screen 21 is larger than that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com