Structure of alternative folding flange type steel plate shear key and construction method thereof

A steel plate shear force and flange plate technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve problems such as difficulty in penetrating round holes, and achieve the effect of reducing perforation operations, avoiding cumbersome procedures and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

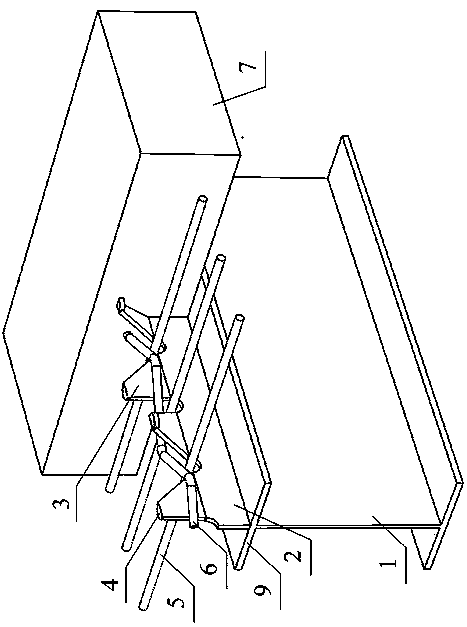

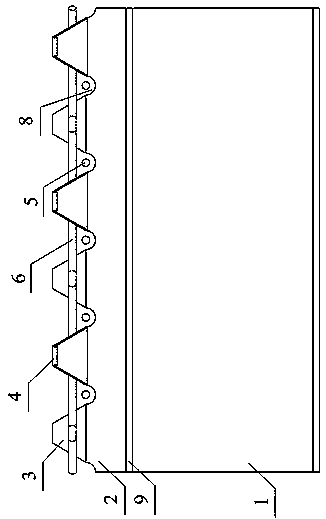

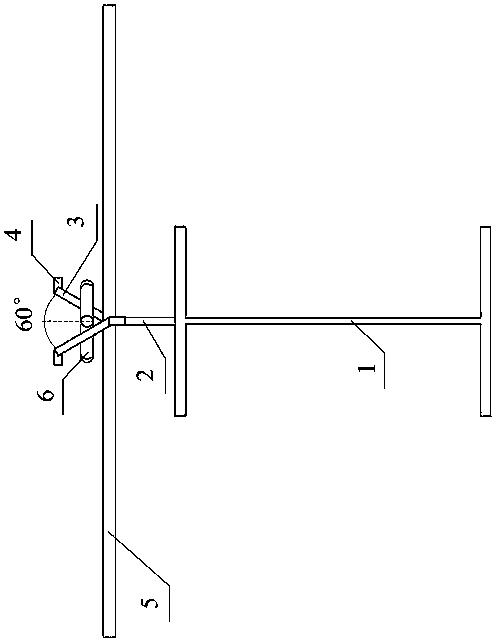

[0043] A structure of alternately folded flange-type steel plate shear keys, such as Figure 1~4 As shown, the lower steel girder 1 adopts section steel, and the upper flange of the lower steel girder 1, that is, the top plate 9 of the steel girder, is welded with alternately folded flange-shaped steel plate shear keys, and the shear key ribs 2 are provided with semicircular holes 8 , the upper part is the trapezoidal flange plate 3 and the semicircular end plate 4 which are alternately folded, the transverse through steel bar 5 is placed in the semicircular hole 8, and the longitudinally bent steel bar 6 is placed between the flange plates.

[0044] The ribs 2 are vertically arranged with the steel beam roof 9, the ribs 2 are arranged along the length direction of the steel beam roof 9, the ribs 2, the trapezoidal flange plate 3, the semicircular end plate 4, the transverse through reinforcement 5 and the longitudinal bending reinforcement 6 is completely poured into the conc...

Embodiment 2

[0061] A structure of alternately folded flange-type steel plate shear keys, such as Figure 11 As shown, a steel box girder 10 is used including the lower steel girder, and 2 sets of alternately folded flange-shaped steel plate shear keys are welded on the upper flange of the steel box girder, that is, the top plate 7 of the steel girder.

[0062] In the present embodiment, the thickness of the rib plate 2 and the trapezoidal flange plate 3 is 16mm, the height of the rib plate 2 is 100mm, the height of the trapezoidal flange plate 3 is 80mm, and the included angle of the trapezoidal flange plate 3 is 90 °, and the semicircle hole 8 and The diameter of the semicircular end plate 4 is 60mm, the spacing is 200mm, the diameter of the transverse through reinforcement 5 and the longitudinal bending reinforcement 6 is 28mm, and the bending radius of the longitudinal bending reinforcement 6 is 40mm.

[0063] Other structures and construction methods of this embodiment are the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com