Die conveying system for aerated concrete block delaying curing stage and operating method

A technology for aerated concrete and conveying systems, applied in conveyors, mechanical conveyors, manufacturing tools, etc., can solve problems such as easy collision between molds, difficult control of acceleration and deceleration, and complicated layout, and achieve simple structure and smooth operation Reliable, simple process layout results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

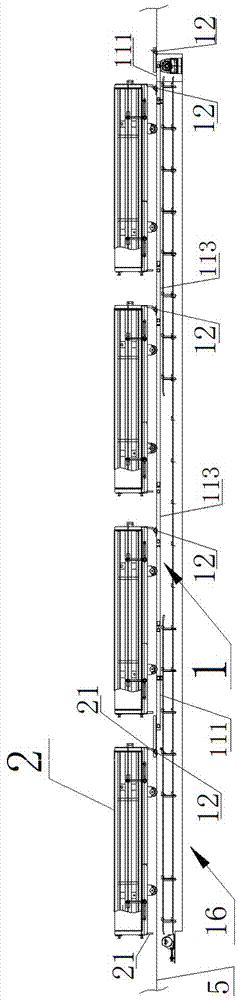

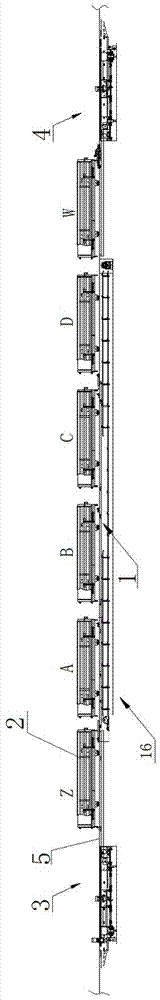

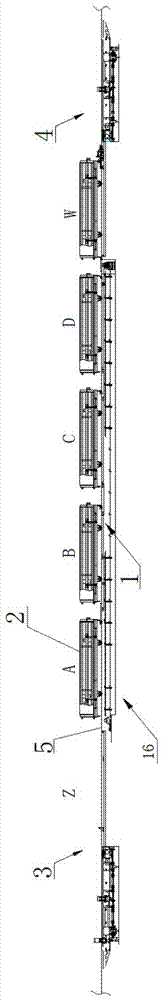

[0073] Such as figure 1 , 4 As shown in , 5, the mold conveying system in the static stop maintenance stage of the aerated concrete block includes a multi-push traction mechanism 1; the multi-push traction mechanism 1 includes a plurality of traction devices that can reciprocate and are rigidly connected to each other in a straight line; each traction device The one-way turning mechanism 12 is respectively arranged on it; the one-way turning mechanism 12 cooperates with the contact baffle plate 21 provided on the mold 2 to be maintained; the one-way turning mechanism 12 contacts the contact baffle plate 21 provides one-way thrust; the transport of the mold 2 to be maintained can be realized through the reciprocating motion of the traction device, the structure is simple, and the operation is stable.

[0074] Such as Figures 15 to 18 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com