Forced oxidizing method and its device for smoke desulfurizing intermediate product-calcium sulfite

A technology of calcium sulfite and forced oxidation, applied in chemical instruments and methods, calcium/strontium/barium sulfite, separation methods, etc., can solve problems such as easy to be blocked by scaling, complex structure, high cost, etc. Reasonable position layout, sufficient forced oxidation, guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

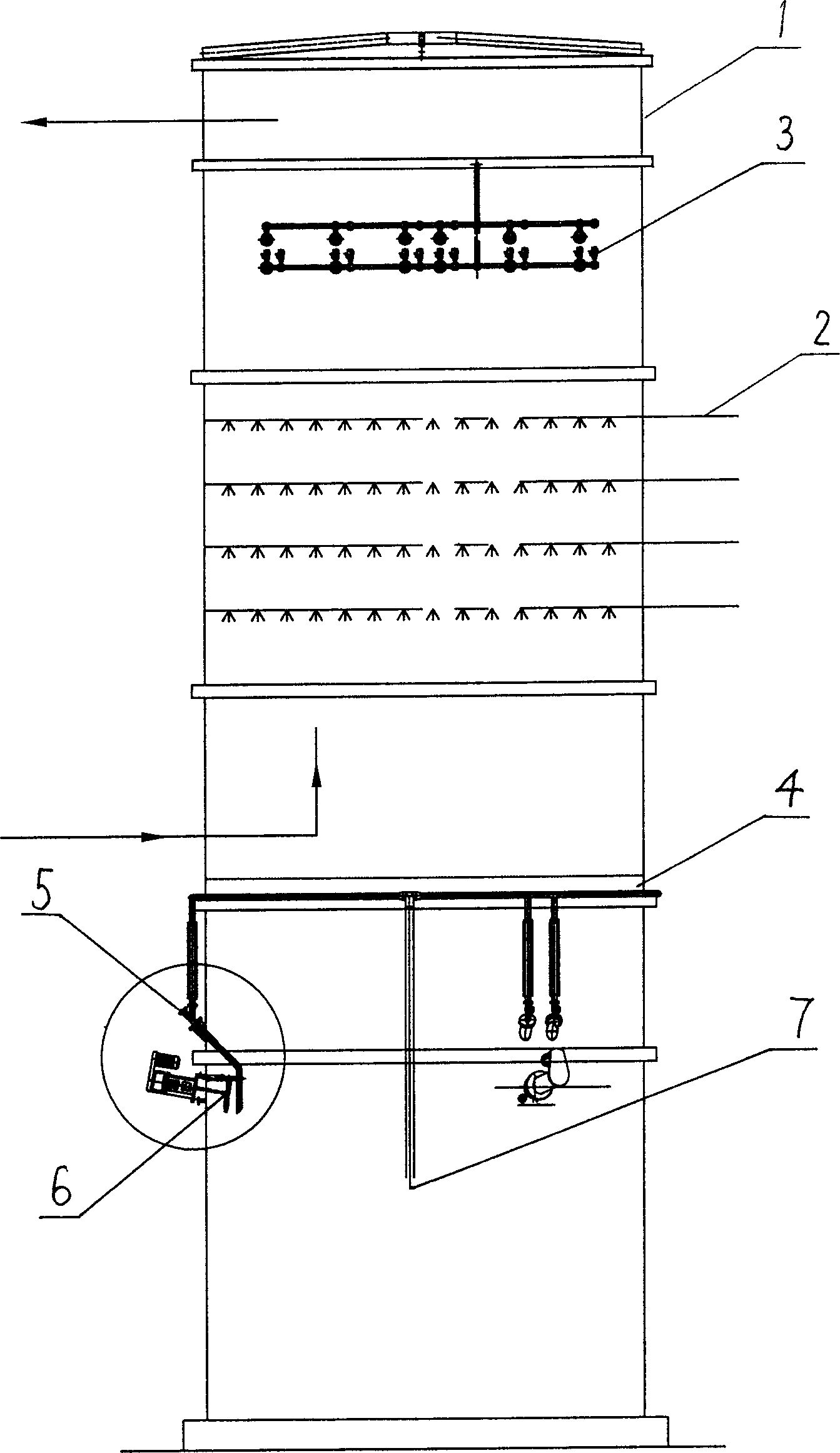

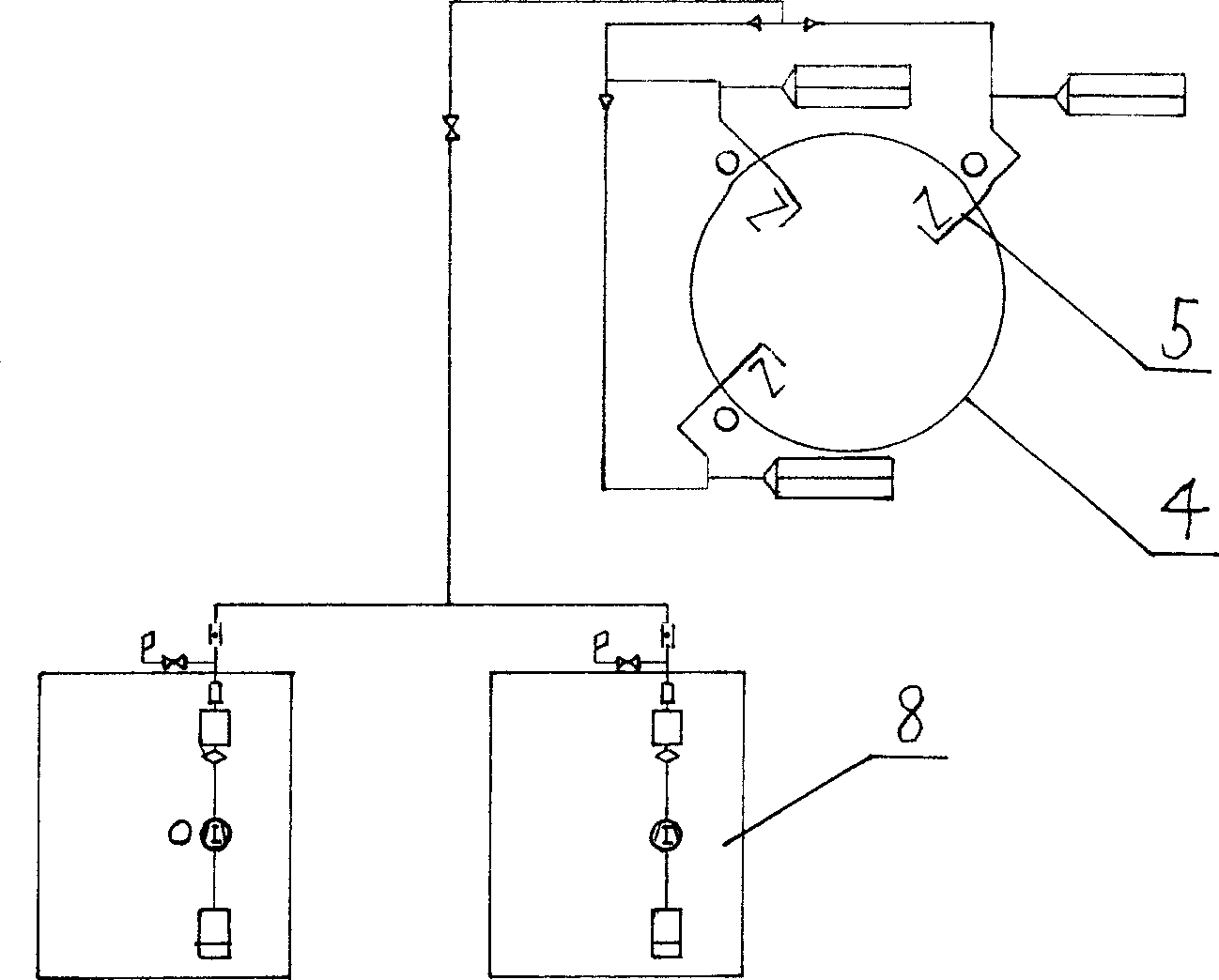

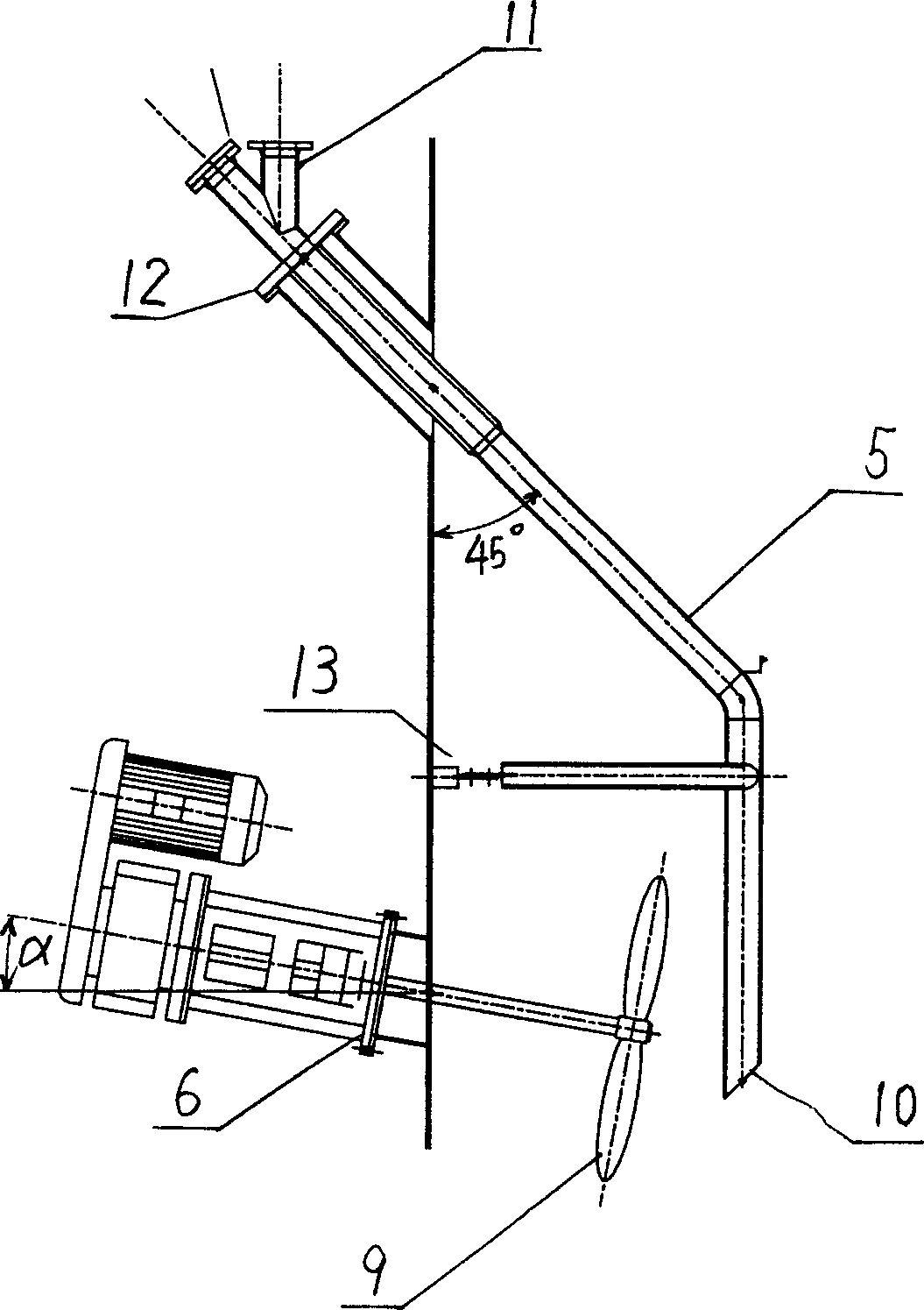

[0026] For an implementation example, see the attached figure 1 , the bottom of the absorption tower 1 is a gypsum slurry pool 4, and the upper part is a reaction section. In the reaction section, the slurry is fully contacted with the flue gas through the spray system 2, and then demisted by the demister 3 to absorb sulfur dioxide in the flue gas. And react to generate calcium sulfite. The absorption tower is equipped with 2-3 sets of air spray guns 5, the air spray guns are inserted under the liquid surface of the slurry pool, and the hot air is blown into the slurry pool below the liquid surface through the oxidation air inlet 7, and the calcium sulfite in the slurry is fully oxidized by the oxygen in the air to form Dihydrate gypsum that can be dehydrated and comprehensively utilized. The side entry agitator 6 is fixed between the inner wall of the absorption tower 1 and the air spray gun 5 at an angle of 3°-30° to the horizontal direction. The output of the whole system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com