Semiautomatic brick unloading, grouping and stacking device and method for sintered bricks

A kind of sintered brick, semi-automatic technology, applied in the direction of object stacking, object destacking, transportation and packaging, etc., can solve the problems of no improvement in manual labor intensity, complex process layout, poor stability of the whole machine, etc., and achieve high application promotion Value, simple process layout, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in combination with specific embodiments.

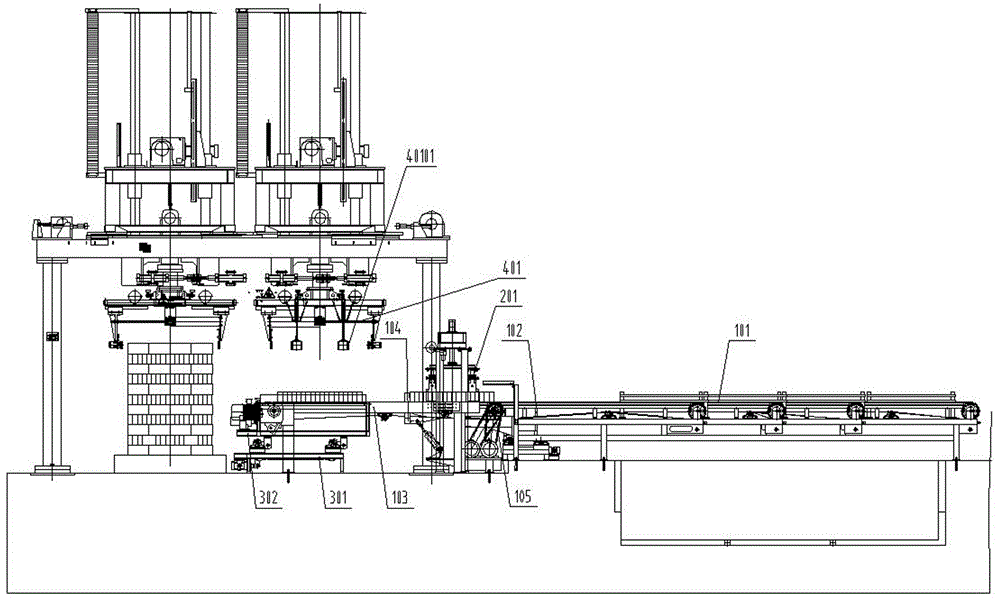

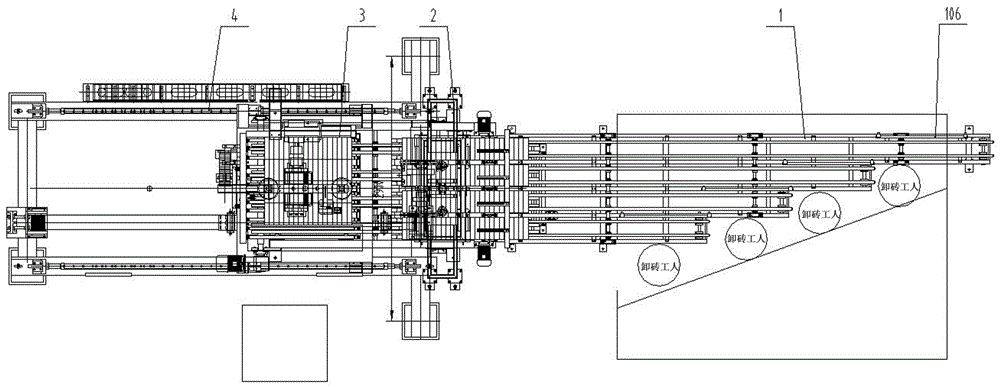

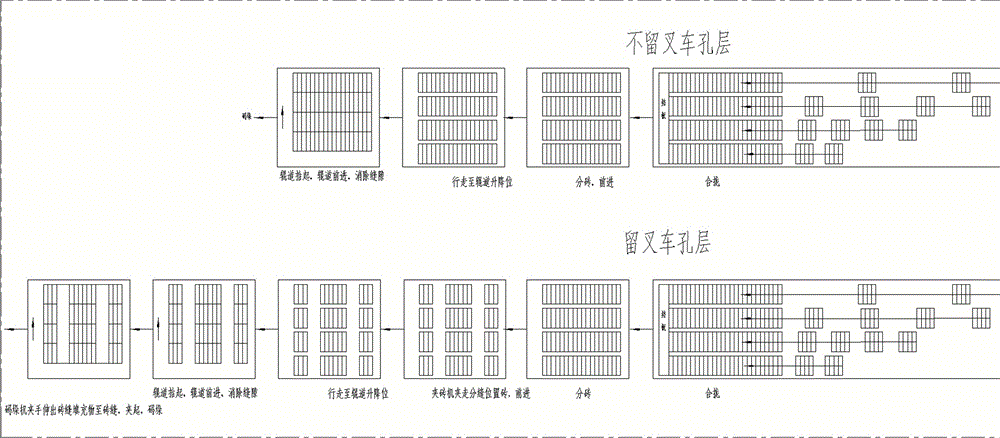

[0020] As shown in the figure: a semi-automatic brick unloading, grouping and stacking device for sintered bricks. Including conveyor chain mechanism I101, brick lifting mechanism 102, conveyor chain mechanism II103 and brick aligning mechanism 104, conveyor chain mechanism I101 and conveyor chain mechanism II103 share the intermediate shaft 105, brick aligning mechanism 104 is located below conveyor chain mechanism II103; brick lifting mechanism 102 It is located under the conveyor chain mechanism I101; the conveyor chain mechanism I101 includes multiple sets of conveyor chains arranged in order of length, and the side of the longest conveyor chain is provided with a stop bar 106, and each set of conveyor chains is controlled by a different motor to achieve different speeds , one or several brick unloading workers at each station in front of the four groups of conveyor ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com