Beam type heat storage lime kiln

A lime kiln and heat storage technology, applied in the fields of chemical production equipment and building materials, can solve problems such as fuel gas preheating, and achieve the effects of increasing the combustion temperature, being beneficial to environmental protection and optimizing the calcination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

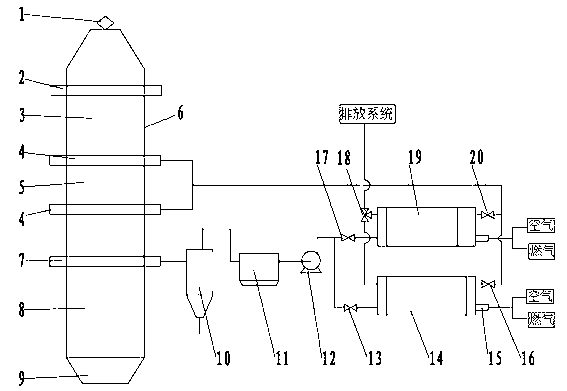

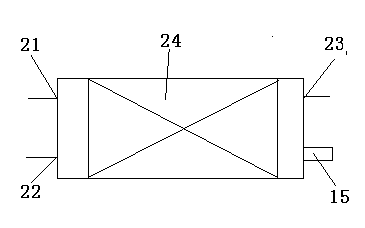

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] The beam type regenerative lime kiln of the present invention such as figure 1 As shown, it includes kiln body 6, feed system 1, air supply system, discharge system, cyclone dust collector 10, bag filter 11, induced draft fan 12, No. 1 regenerator 19, No. 2 regenerator 14, waste gas Emission systems and control systems. The kiln body is provided with a feed inlet, a preheating zone 3 , a calcining zone 5 , a cooling zone 8 and a discharge port 9 . The upper part of the preheating zone is provided with two upper suction beams 2, and the middle part of the cooling zone is provided with three lower suction beams 7. The calcining zone is provided with two layers of combustion beams 4, the upper layer is provided with 4 combustion beams, the lower layer is provided with 3 combustion beams, and the upper and lower layers of combustion beams are arranged alternatel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com