Built-in chimney flue type energy-saving environment protective smelting lime calcining kiln

An energy-saving, environment-friendly, flue-type technology, applied in the field of calcining kilns, can solve the problems of low utilization rate of heat energy, incomplete combustion of gas, and high energy consumption, and achieve the effects of high quality of finished products, good calcination effect, and appropriate amount of flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection content of the present invention is not limited to this embodiment.

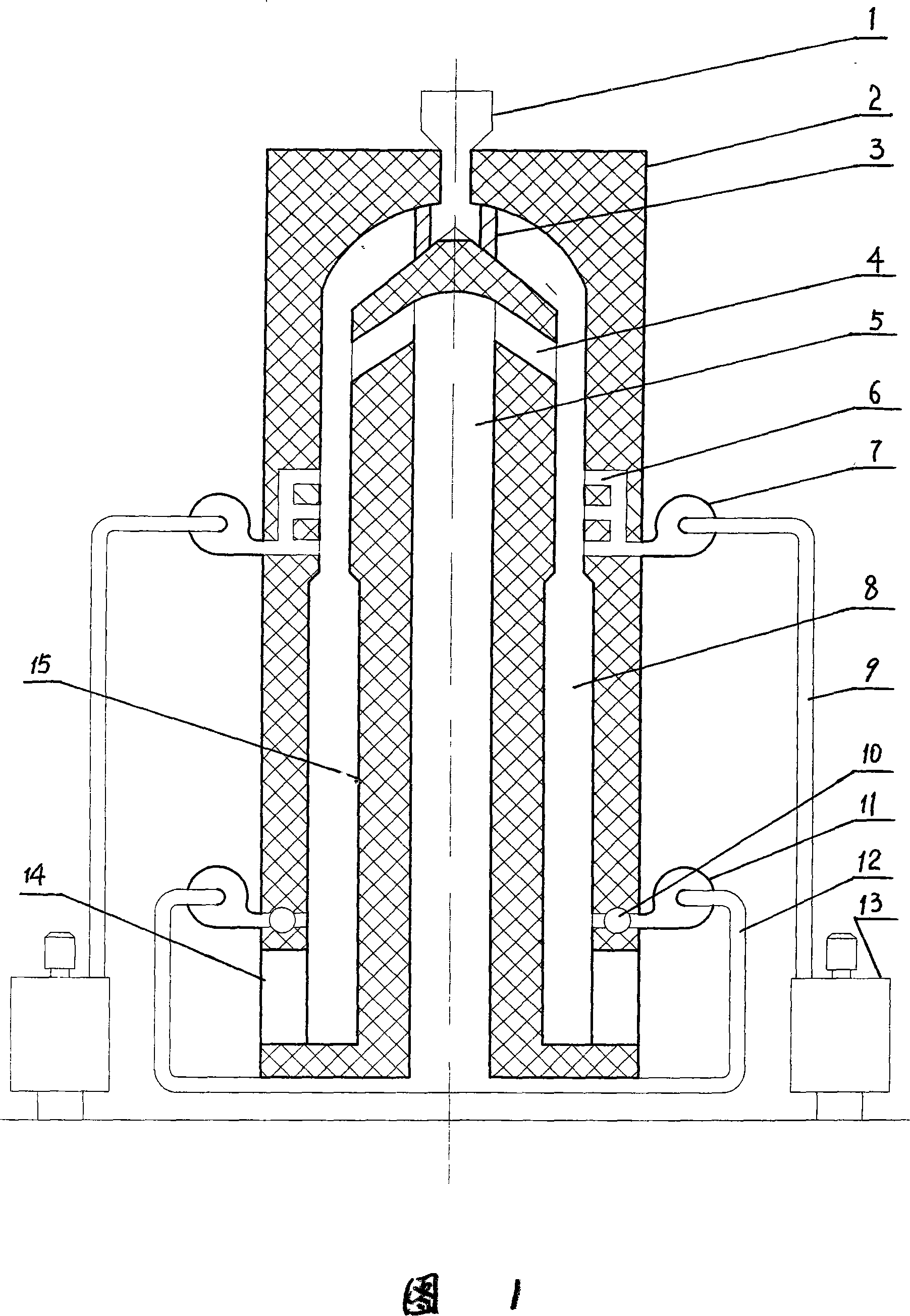

[0014] As shown in Figure 1, this embodiment includes a kiln body 2 with a hopper 1 at the upper end and a discharge port 14 at the lower end. The discharge ports 14 are four evenly distributed front, rear, left and right. The upper end of the inner cavity of the kiln body 2 is hemispherical.

[0015] Offer three layers of fire inlets 6 on the side of the kiln body 2, each layer of twelve. The fire inlet hole 6 is respectively connected with two gas furnaces 13 through the gas pipe 9, and two upper induced draft fans 7 are respectively installed on the side of the kiln body 2 through brackets, and the upper induced draft fan 7 provides a mechanism for blowing gas into the inner cavity of the kiln body 2. power.

[0016] A built-in chimney 15 is arranged in the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com