Novel multi-fuel sleeve type lime kiln

A multi-fuel, sleeve-type technology, applied in the field of lime kiln, can solve the problems of low daily output and low calcination efficiency, and achieve the effects of increasing capacity, increasing calcining efficiency, and improving calcining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

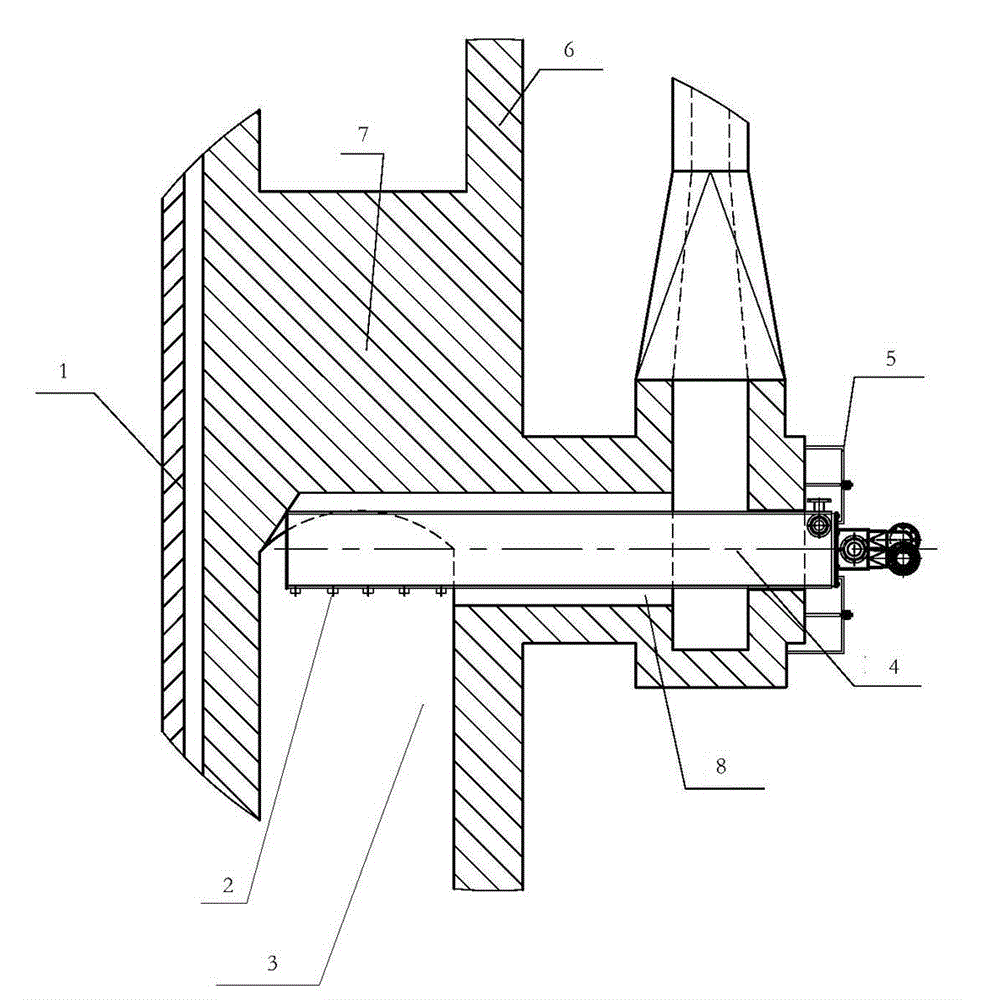

[0010] figure 1 As shown, the main structure of the multi-fuel sleeve type lime kiln is the same as that of the prior art. It consists of a kiln shell 6 , an upper inner sleeve (not shown) located in the kiln shell, and a lower inner sleeve 1 , and a calcining annular passage 3 is formed between the kiln shell 6 and the lower inner sleeve 1 . The annular passage 3 is provided with an arch bridge 7 and two rows of combustion chambers 8 distributed at intervals above and below. The multi-fuel sleeve type lime kiln of the present invention is provided with a combustion beam 4 in the combustion chamber, and the combustion beam 4 extends from the kiln shell wall body to the annular passage 3; A burner 2 is provided. The combustion beam can use existing structures in the prior art, and the fuel used can be pulverized coal, gas, heavy oil and the like. The end of the combustion beam in the present invention protrudes from the kiln body and is provided with a fixed platform 5 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com