Type A flame path beam for multi-fuel lime shaft kiln

A multi-fuel and lime technology, which is applied in the field of lime shaft kilns and fire beams for multi-fuel lime shaft kilns, can solve problems such as poor calcination effect, low fuel efficiency, and low daily output, and achieve improved calcination uniformity and combustion efficiency High and prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

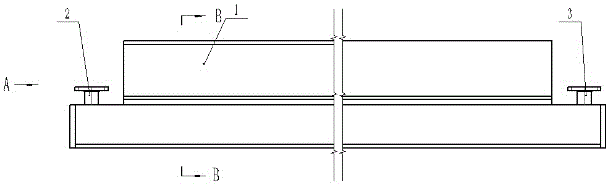

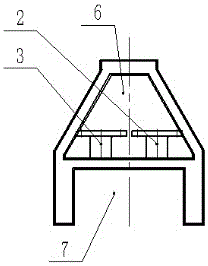

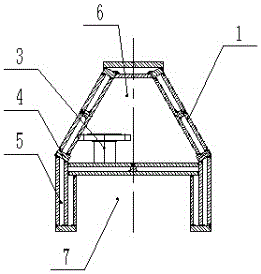

[0018] Please refer to the attached figure 1 As shown, the present invention is an A-type flue beam for a multi-fuel lime shaft kiln, which mainly consists of a beam body 1, a heat transfer oil inlet 2, a heat transfer oil outlet 3 (at the other end of the beam), a blocking plate 4, and a heat transfer oil The primary cooling channel 5, the beam secondary cooling channel 6, and the flame channel 7 are composed of several parts.

[0019] Among them, the beam body 1 and the blocking plate 4 are welded to form three kinds of channels: the beam secondary cooling channel 6, the flame channel 7 and the heat transfer oil primary cooling channel 5 are formed by welding the beam body 1 and the blocking plate 4, The heat transfer oil flows from the heat transfer oil inlet 2 into the heat transfer oil primary cooling channel 5 and flows out through the heat transfer oil outlet 3 for cooling the fire path beam. The beam secondary cooling channel 6 is formed by the special structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com