Micro-internal mixed catalytic burner

A catalytic burner and internal mixing technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of unsafe pre-mixed combustion gas, large structure of micro burners, etc., and achieve the advantages of preheating and The effect of safety, compact structure and uniform temperature distribution of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

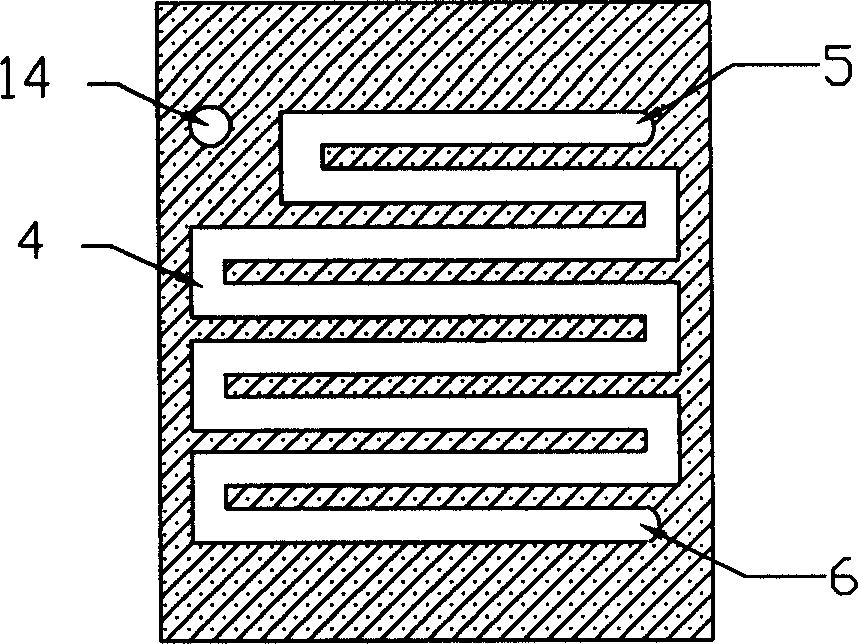

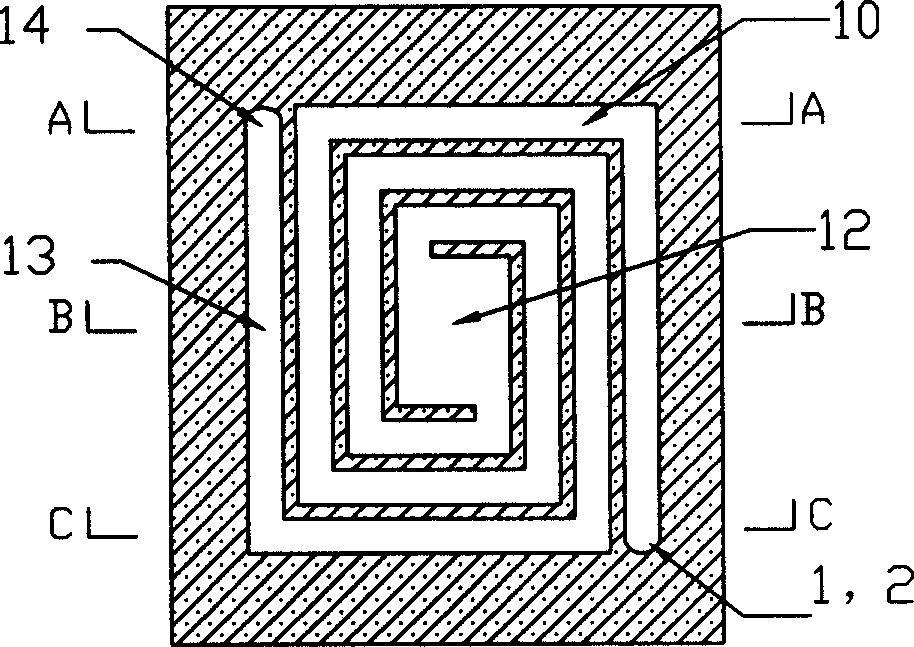

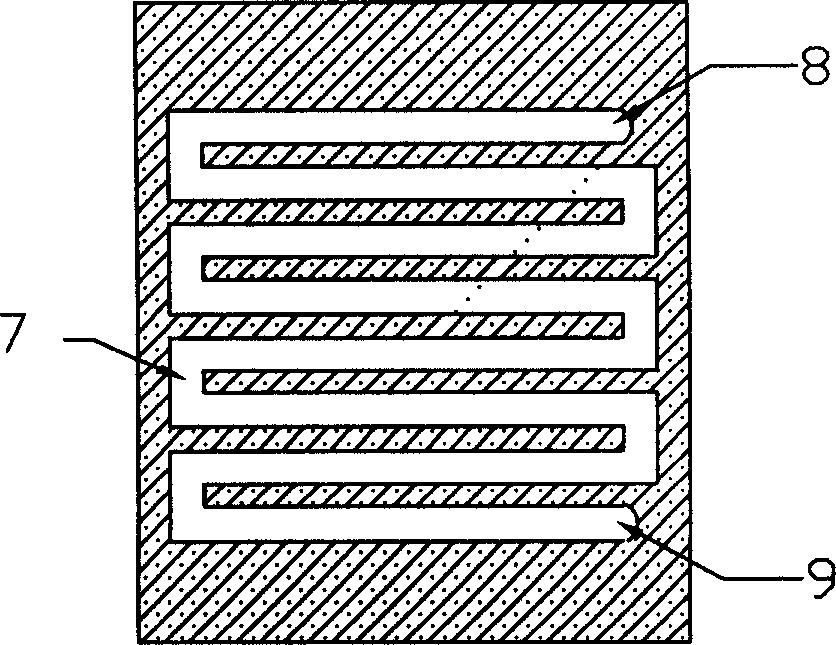

[0027] The structure of the miniature internal mixing type catalytic burner in the specific embodiment 1 is as Figure 1 to Figure 6 shown.

[0028] The micro internal mixing catalytic burner is made of single crystal silicon material, including the upper preheating chamber 1, the combustion chamber 2 and the lower preheating chamber 3, the upper and lower preheating chamber 1, the lower preheating chamber 3 and the upper and lower surfaces of the combustion chamber 2 Bonding forms a three-layer structure.

[0029] The inside of the upper preheating chamber 1 and the lower preheating chamber 3 are respectively etched by MEMS processing, and the upper preheating chamber preheating channel 4 and the lower preheating chamber 7 are respectively etched outside the upper preheating chamber and the lower preheating chamber. The upper preheating chamber preheating channel inlet 5 and the lower preheating chamber preheating channel inlet 8 are formed on the surface. The preheating pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com