Photovoltaic cell with self-radiating composite cathode buffer layer and preparation method thereof

A cathode buffer layer, composite cathode technology, applied in photovoltaic power generation, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing the weight and thickness of the battery, damaging the structure of each layer of the battery, etc., to improve the photoelectric conversion efficiency, increase Effect of electron mobility and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

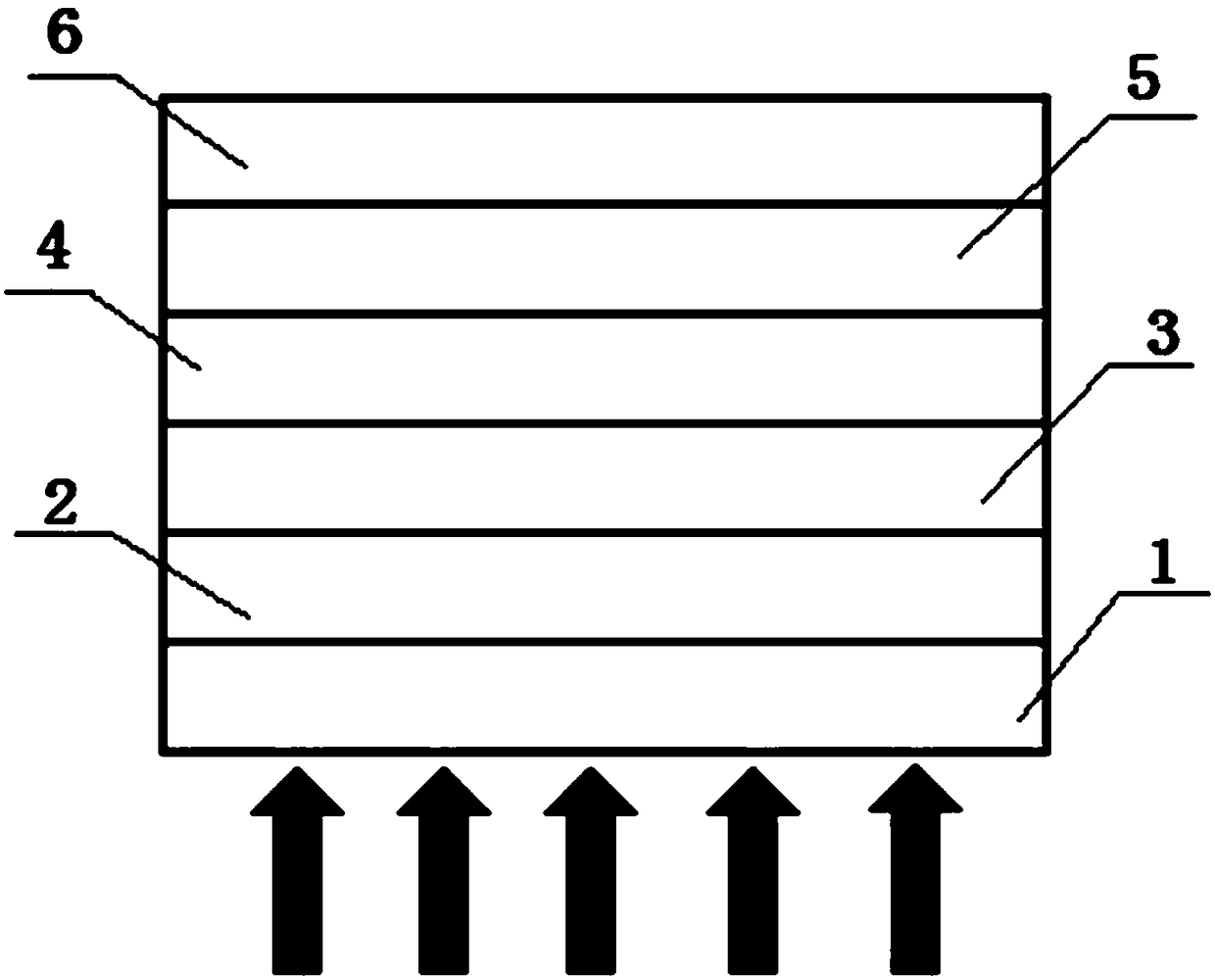

[0035] Such as figure 1 As shown, a photovoltaic cell with a self-heating composite cathode buffer layer adopts an inverted structure, and is arranged in sequence from bottom to top: substrate 1, transparent conductive cathode ITO 2, composite cathode buffer layer 3, photoactive layer 4, anode Buffer layer 5, metal anode 6, the composite cathode buffer layer 3 is composed of cathode buffer layer 31 and heat dissipation grid 32.

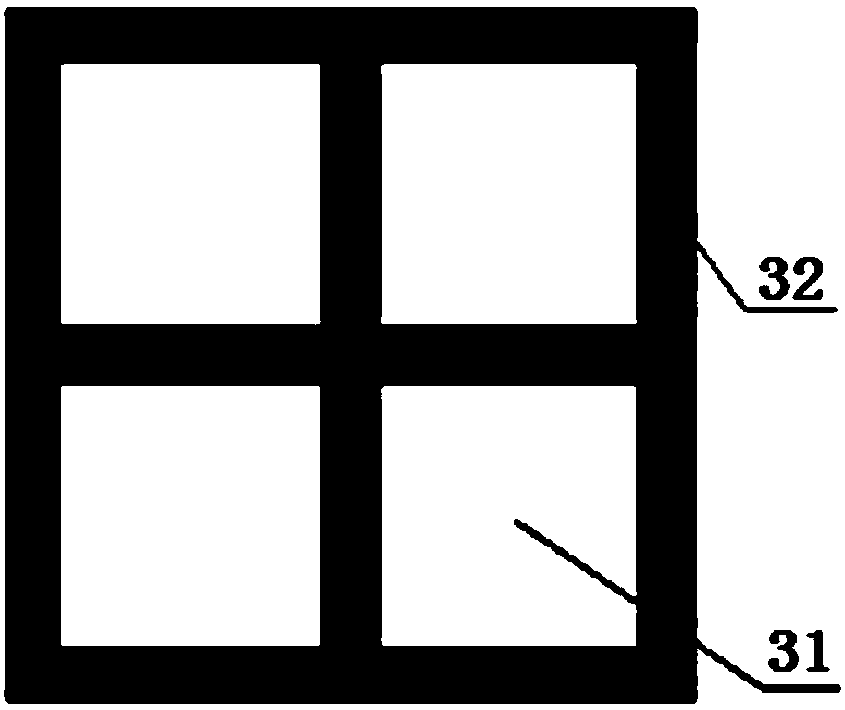

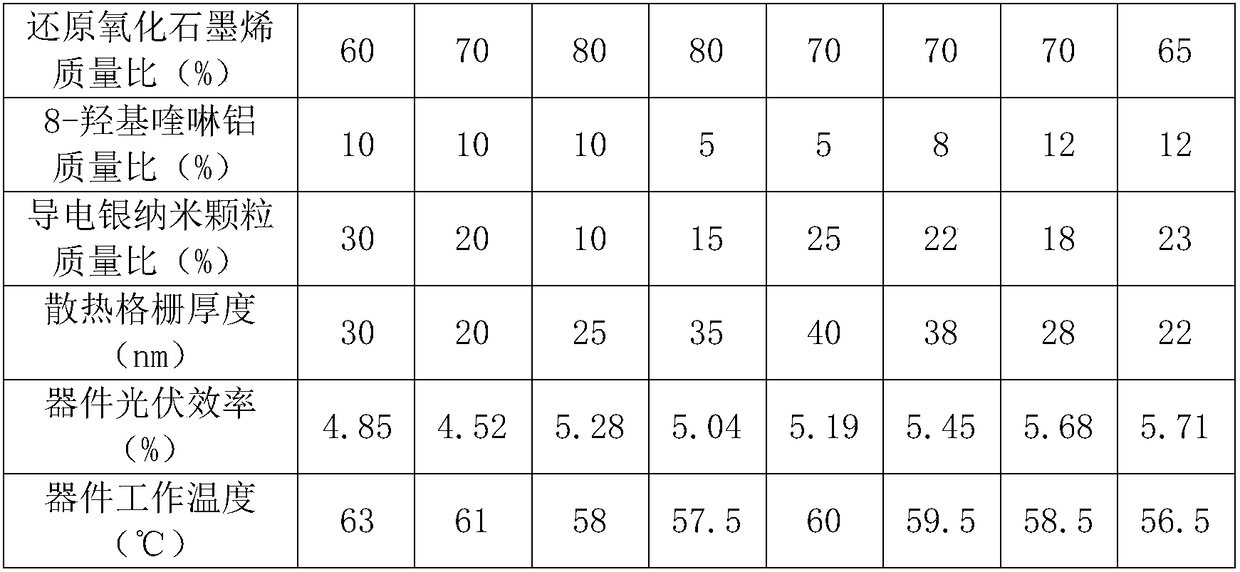

[0036] The structure of the present embodiment composite cathode buffer layer 3 is as follows figure 2 As shown, the heat dissipation grid 32 is in the shape of a square, and the mass percentages of the components in the heat dissipation grid 32 are: 60% of reduced graphene oxide, 10% of 8-hydroxyquinoline aluminum, 30% of conductive silver nanoparticles, The heat dissipation grid 32 has a thickness of 30 nm.

[0037] A method for preparing a photovoltaic cell with a self-radiating composite cathode buffer layer provided in this embodiment is as fo...

Embodiment 2

[0040] Such as figure 1 As shown, a photovoltaic cell with a self-heating composite cathode buffer layer adopts an inverted structure, and is arranged in sequence from bottom to top: substrate 1, transparent conductive cathode ITO 2, composite cathode buffer layer 3, photoactive layer 4, anode Buffer layer 5, metal anode 6, the composite cathode buffer layer 3 is composed of cathode buffer layer 31 and heat dissipation grid 32.

[0041] The structure of the present embodiment composite cathode buffer layer 3 is as follows figure 2 As shown, the heat dissipation grid 32 is in the shape of a square, and the mass percentages of the components in the heat dissipation grid 32 are: 70% of reduced graphene oxide, 10% of 8-hydroxyquinoline aluminum, 20% of conductive silver nanoparticles, The heat dissipation grid 32 has a thickness of 20 nm.

[0042] A method for preparing a photovoltaic cell with a self-radiating composite cathode buffer layer provided in this embodiment is as fo...

Embodiment 3

[0045] Such as figure 1 As shown, a photovoltaic cell with a self-heating composite cathode buffer layer adopts an inverted structure, and is arranged in sequence from bottom to top: substrate 1, transparent conductive cathode ITO 2, composite cathode buffer layer 3, photoactive layer 4, anode Buffer layer 5, metal anode 6, the composite cathode buffer layer 3 is composed of cathode buffer layer 31 and heat dissipation grid 32.

[0046] The structure of the present embodiment composite cathode buffer layer 3 is as follows figure 2 As shown, the heat dissipation grid 32 is in the shape of a square, and the mass percentages of the components in the heat dissipation grid 32 are: 80% reduced graphene oxide, 10% 8-hydroxyquinoline aluminum, 10% conductive silver nanoparticles, The heat dissipation grid 32 has a thickness of 25 nm.

[0047] A method for preparing a photovoltaic cell with a self-radiating composite cathode buffer layer provided in this embodiment is as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com