Immersed membrane distillation assembly and sewage biological treatment system

A sewage biological treatment, submerged membrane technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of unbalance, reduce concentration polarization, and reduce temperature difference polarization and other problems to achieve the effect of reducing heat loss, weakening concentration polarization, and weakening temperature difference polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

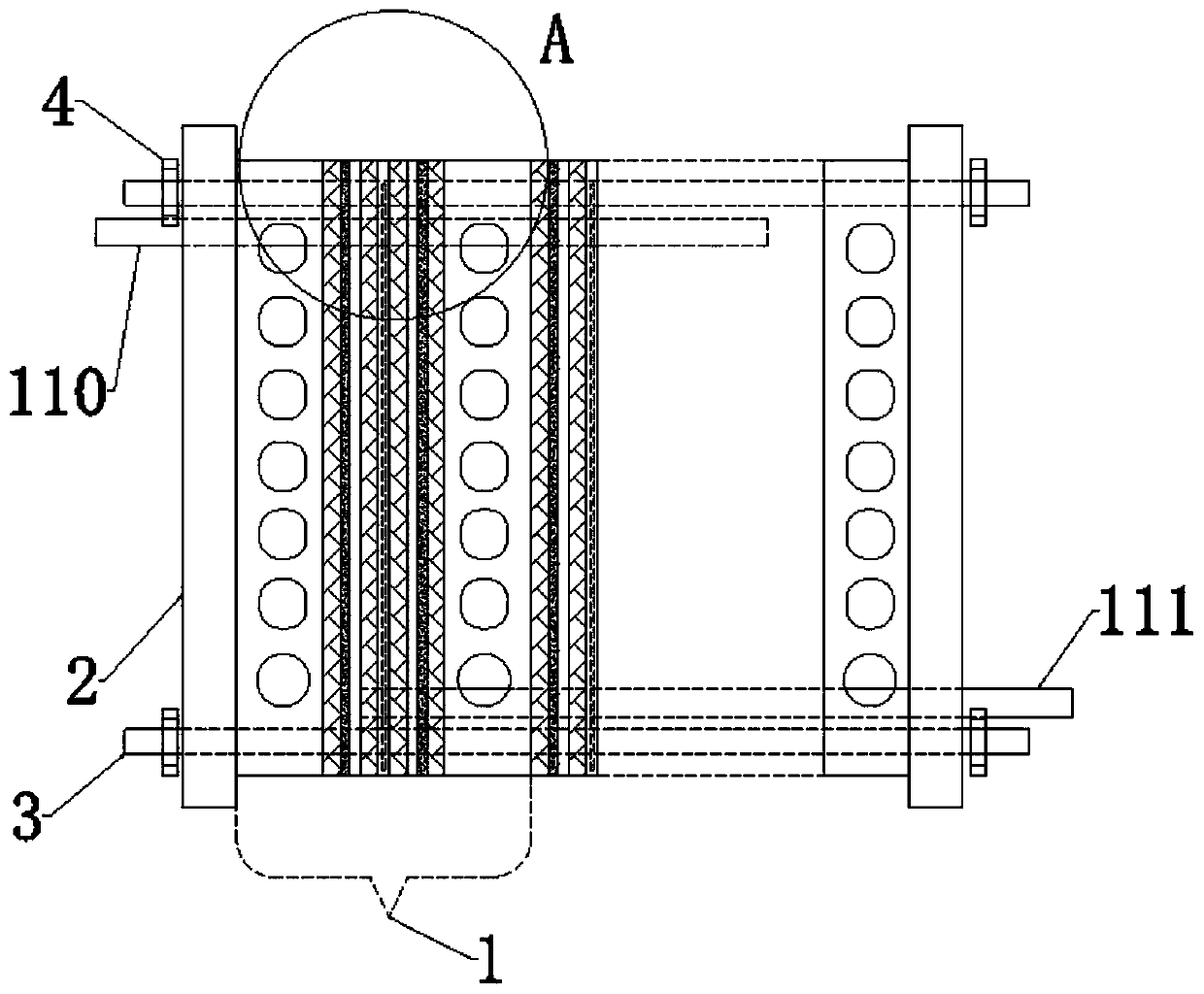

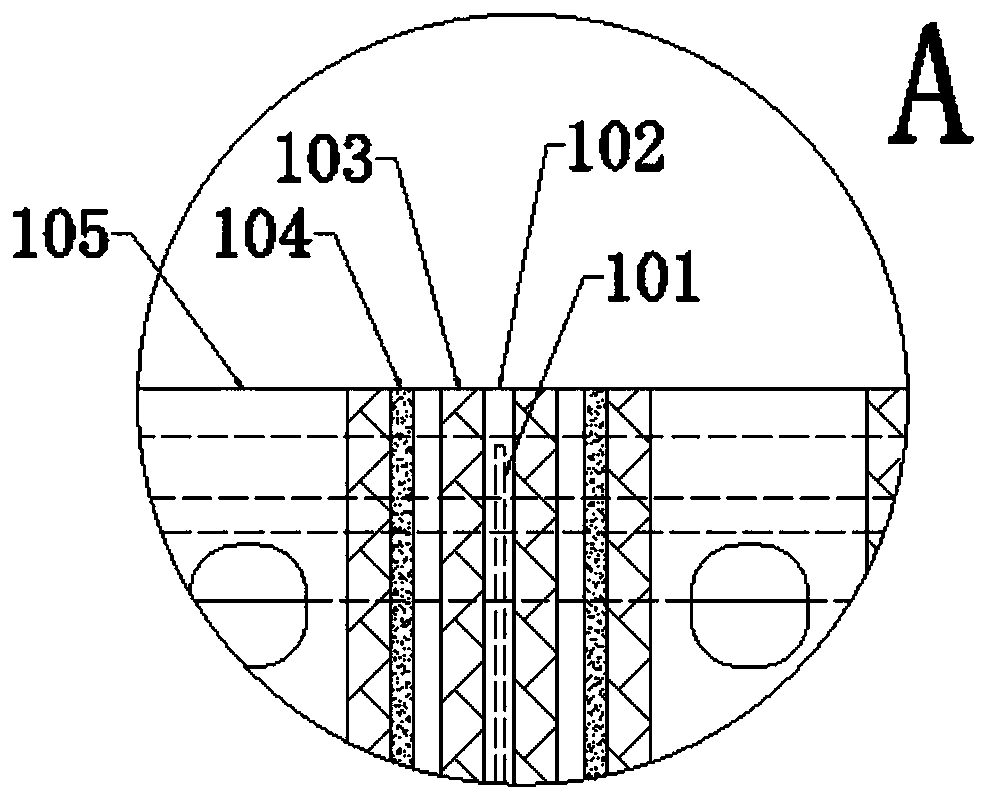

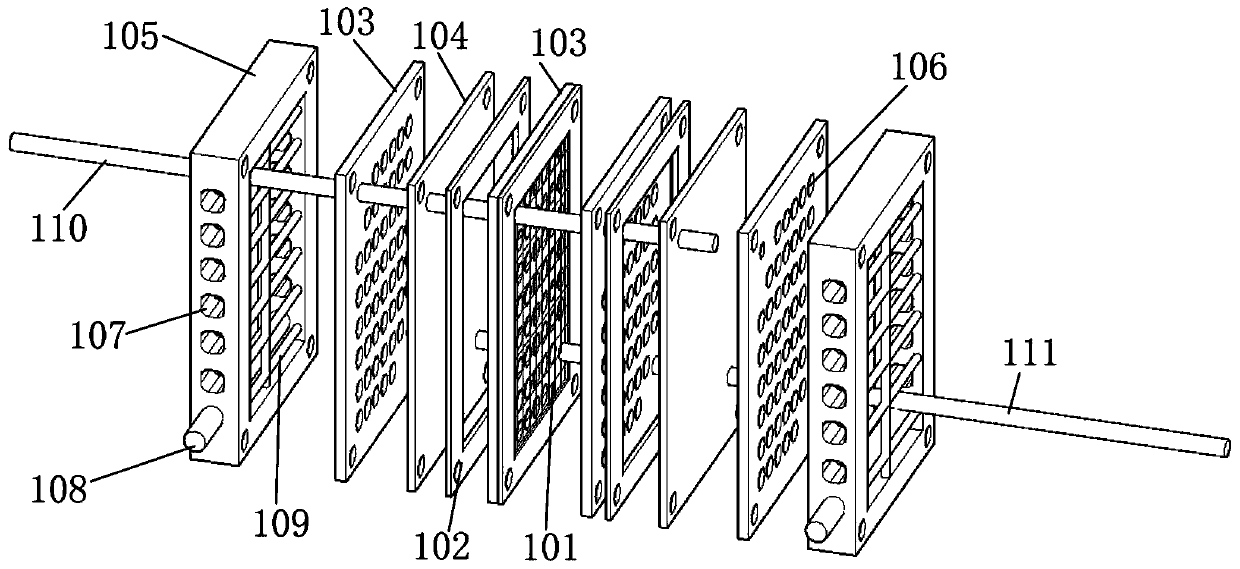

[0033] Such as figure 1 , figure 2 , image 3 , Image 6 As shown, a submerged membrane distillation assembly includes several membrane distillation units 1 and installation plates 2 arranged on both sides of the several membrane distillation units 1, and the installation plates 2 and several membrane distillation units 1 are arranged through There are a plurality of bolt rods 3, and nuts 4 are screwed on both ends of the bolt rods 3 to fasten the mounting plate 2 and several membrane distillation units 1 together, and the membrane distillation units 1 include a plastic Screen 101, the plastic screen 101 is arranged in the middle of the gasket 102, and the left and right sides of the plastic screen 101 are provided with a support plate 103, a gasket 102, a microporous hydrophobic film 104, a support plate in sequence from near to far. Plate 103 and component frame 105, the gasket 102 is a rectangular frame hollowed out in the middle, the support plate 103 is a pp board wit...

Embodiment 2

[0036] Such as Figure 4 , Figure 5 , Figure 7 As shown, a submerged membrane distillation assembly includes several membrane distillation units 1 and installation plates 2 arranged on both sides of the several membrane distillation units 1, and the installation plates 2 and several membrane distillation units 1 are arranged through There are a plurality of bolt rods 3, and nuts 4 are screwed on both ends of the bolt rods 3 to fasten the mounting plate 2 and several membrane distillation units 1 together, and the membrane distillation units 1 include a plastic Screen 101, the plastic screen 101 is arranged in the middle of the gasket 102, and the left and right sides of the plastic screen 101 are sequentially provided with a condensation plate 112, a gasket 102, a support plate 103, and a gasket 102 from near to far. , microporous hydrophobic membrane 104, support plate 103 and component frame 105, described gasket 102 is the rectangular frame that the middle part is hollo...

Embodiment 3

[0039] Such as figure 1 , figure 2 , image 3 , Figure 8 As shown, a submerged membrane distillation assembly includes several membrane distillation units 1 and installation plates 2 arranged on both sides of the several membrane distillation units 1, and the installation plates 2 and several membrane distillation units 1 are arranged through There are a plurality of bolt rods 3, and nuts 4 are screwed on both ends of the bolt rods 3 to fasten the mounting plate 2 and several membrane distillation units 1 together, and the membrane distillation units 1 include a plastic Screen 101, the plastic screen 101 is arranged in the middle of the gasket 102, and the left and right sides of the plastic screen 101 are provided with a support plate 103, a gasket 102, a microporous hydrophobic film 104, a support plate in sequence from near to far. plate 103 and component frame 105, the gasket 102 is a rectangular frame hollowed out in the middle, the support plate 103 is a stainless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com