A Multi-fuel Ring Beam Lime Kiln

A lime kiln and multi-fuel technology, which is applied in the field of multi-fuel ring beam lime kiln and lime kiln, can solve the problems of low calcination efficiency and low daily output, improve product quality, reduce product heat consumption, and achieve calcination penetration powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

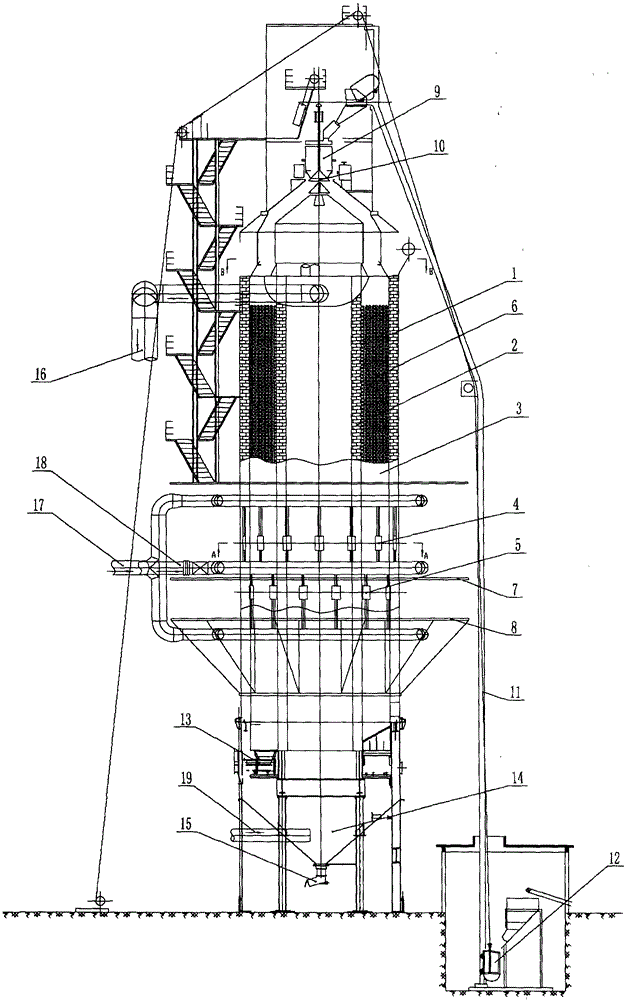

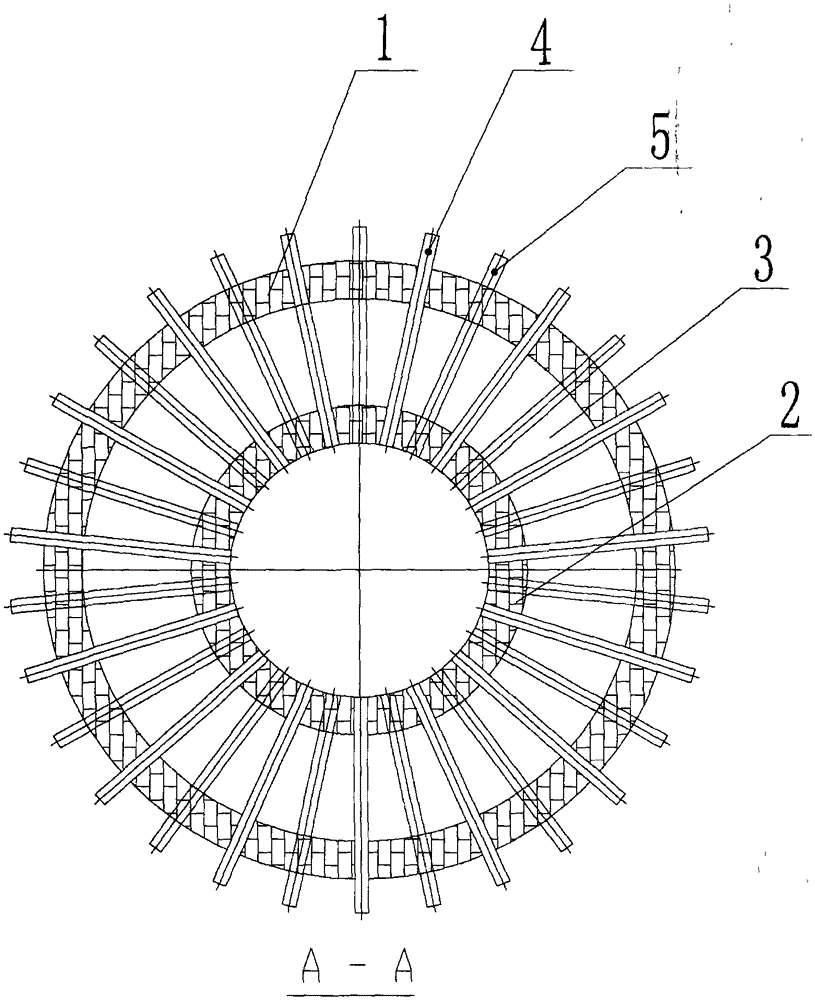

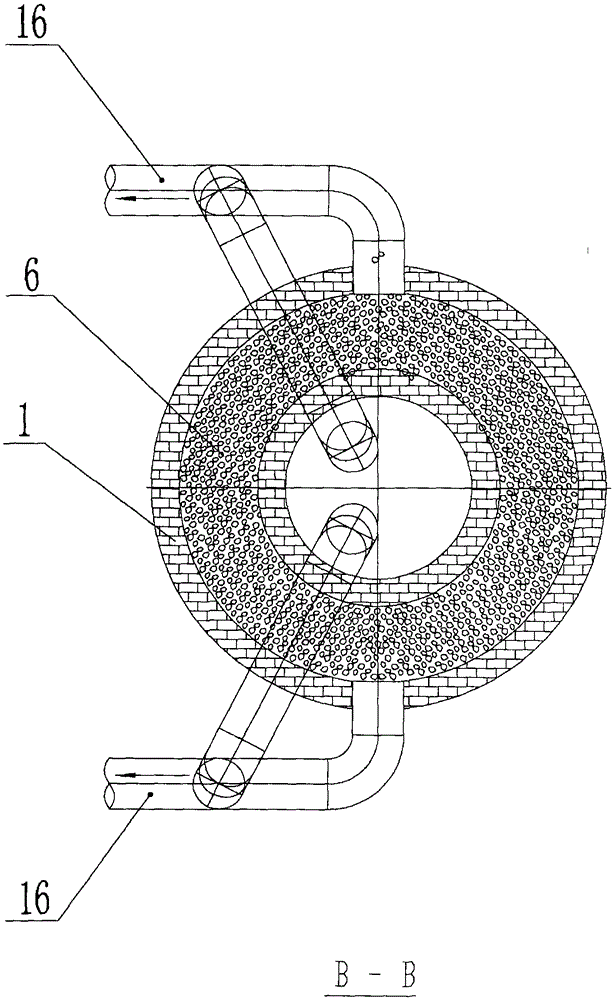

[0018] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a multi-fuel ring beam lime kiln, which mainly consists of a kiln shell 1 and an inner cylinder 2 located in the kiln shell 1 and other two parts.

[0019] Wherein, an annular calcining area 3 is formed between the kiln shell 1 and the inner cylinder 2, and the limestone 6 is accommodated in the annular calcining area 3, and the limestone 6 is calcined. The annular calcining area 3 is provided with an upper layer of combustion beams 4 and a lower layer of combustion beams 5, and the upper layer of combustion beams 4 and the lower layer of combustion beams 5 are distributed alternately in two rows, upper and lower. The upper combustion beam 4 and the lower combustion beam 5 respectively extend from the side wall of the kiln shell 1 to the inner tube 2 through the annular calcining zone 3 . Several burners (not shown) are respectively arranged on the upper combustion beam 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com