A lithium-ion battery nickel-cobalt lithium manganate positive electrode material and preparation method thereof

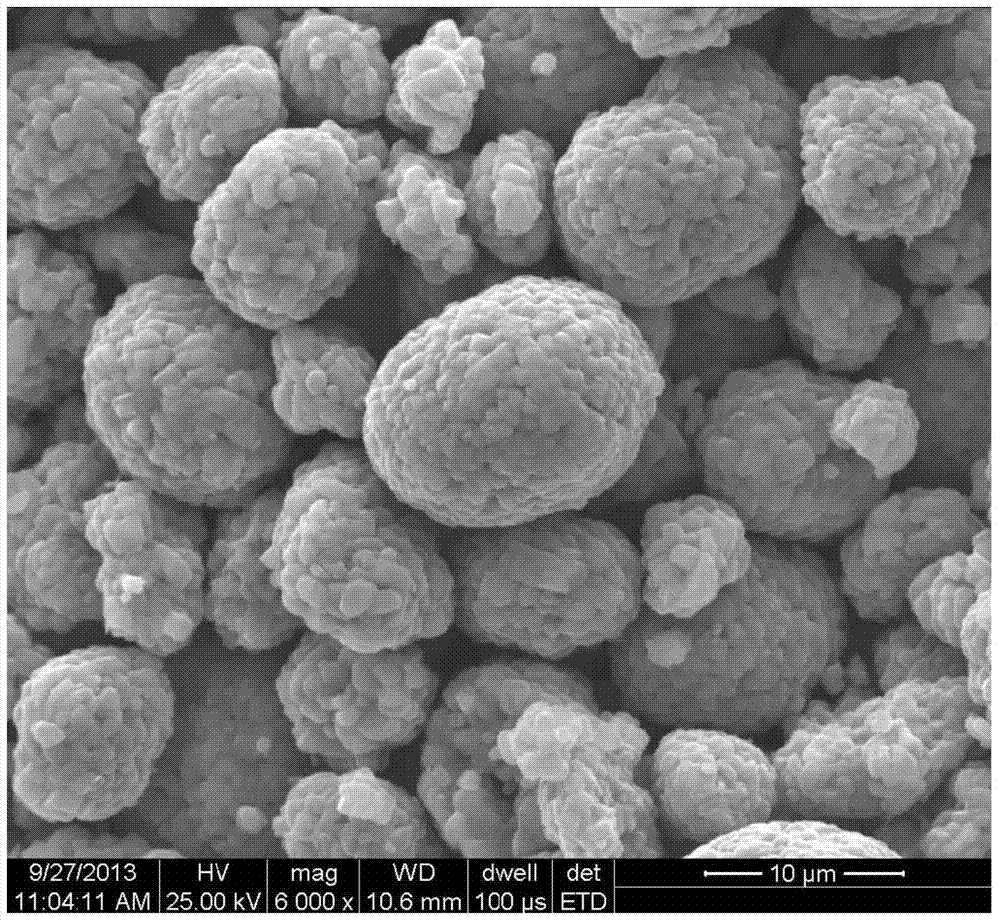

A technology for nickel-cobalt lithium manganate and lithium-ion batteries, which is applied in the field of lithium-ion battery nickel-cobalt lithium manganate cathode materials and their preparation, can solve the problems of irregular particle shape and uneven size, and achieve uniform morphology and size. Uniform, regular shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The first aspect of the present invention provides a method for preparing a lithium-ion battery nickel-cobalt-lithium manganese oxide positive electrode material, the preparation method comprising the following steps:

[0032] Step 1, dissolving lithium salt, nickel salt, cobalt salt and manganese salt in a solvent according to the ratio of the amount of substances Li:Ni:Co:Mn=(1.01~1.1):x:y:(1-x-y) to obtain The first solution, where 0<x<1, 0<y<1;

[0033] Step 2, adding a chelating agent and a carbon source to the first solution, and mixing uniformly to obtain a second solution; wherein, the ratio of the amount of substances of the chelating agent to the total amount of metal ions in the first solution 1:1~1.2:1;

[0034] Step 3, heating the second solution for 8-12 hours under the condition of vacuum degree of -0.1-0.08MPa and temperature of 80-120°C, and removing the solvent in the second solution to obtain the precursor powder;

[0035] Step 4, in an inert gas at...

Embodiment 1

[0052] An embodiment of the present invention provides a method for preparing a positive electrode material of lithium nickel cobalt manganese oxide, wherein the chemical formula of lithium nickel cobalt manganese oxide is: LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , the amount of carbon coating (carbon accounts for the mass percent of carbon-coated nickel-cobalt-lithium manganese oxide positive electrode material, the same below) is 0.5%, and the steps of the preparation method are as follows:

[0053] Step 1, accurately weigh lithium acetate, nickel acetate, cobalt acetate and manganese acetate according to the ratio of the substance ratio Li:Ni:Co:Mn=1.04:1 / 3:1 / 3:1 / 3, dissolve in deionized Obtain the first solution after water, wherein, the total substance concentration of metal ion is 1mol / L;

[0054] Step 2, adding chelating agent citric acid and carbon source glucose to the first solution, stirring magnetically for 1 hour to mix citric acid and glucose with the first solution to obt...

Embodiment 2

[0060] An embodiment of the present invention provides a method for preparing a positive electrode material of lithium nickel cobalt manganese oxide, wherein the chemical formula of lithium nickel cobalt manganese oxide is: LiNi 0.4 co 0.5 mn 0.1 o 2 , the carbon coating amount is 0.1%, and the steps of the preparation method are as follows:

[0061] Step 1, accurately weigh lithium nitrate, nickel nitrate, cobalt chloride and manganese chloride according to the ratio of the amount of substances Li:Ni:Co:Mn=1.01:0.4:0.5:0.1, and dissolve them in deionized water to obtain the first A solution, wherein the total substance concentration of metal ions is 0.5mol / L;

[0062] Step 2, adding chelating agent triethanolamine and carbon source phenolic resin to the first solution, magnetically stirring for 1 hour to mix triethanolamine and phenolic resin with the first solution to obtain a second solution; wherein, the amount of triethanolamine The ratio with the total amount of meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com