A kind of preparation method of metal oxide layer on the electrolyte surface of sodium battery

A surface metal and electrolyte technology, applied in the field of sodium batteries, can solve the problems of poor stability, uneven internal and external calcination effects, and low quality of sodium batteries, and achieve the effects of improving quality, uniform heating inside and outside, and increasing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

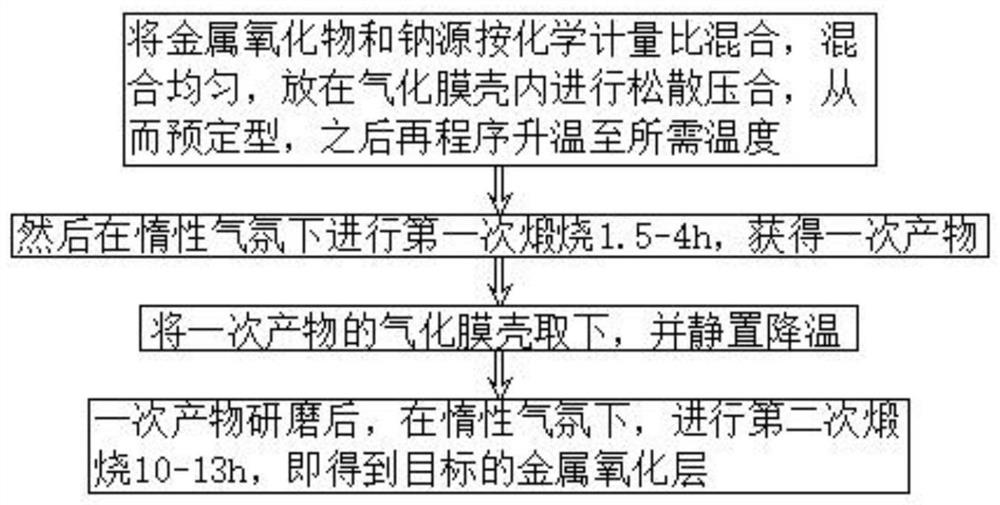

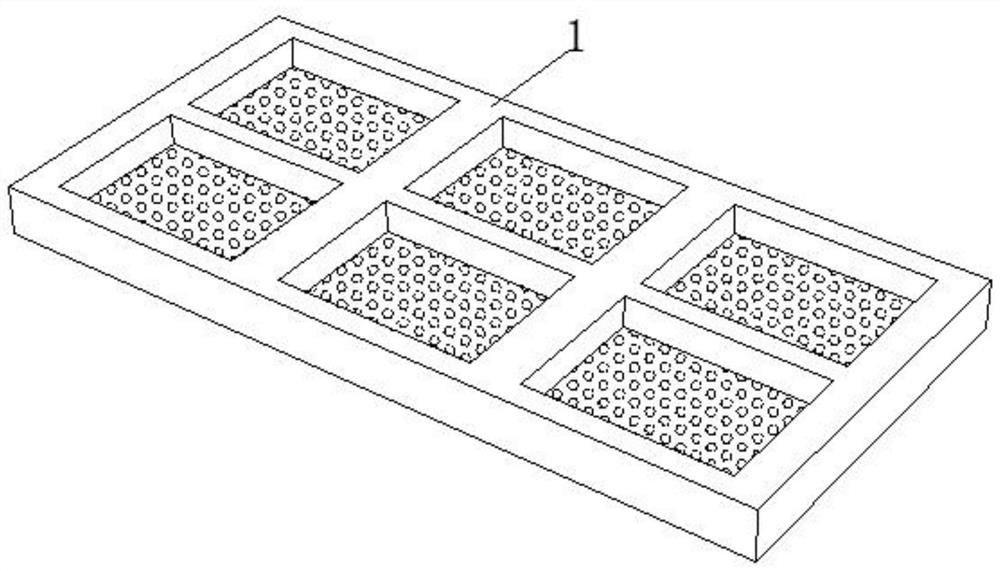

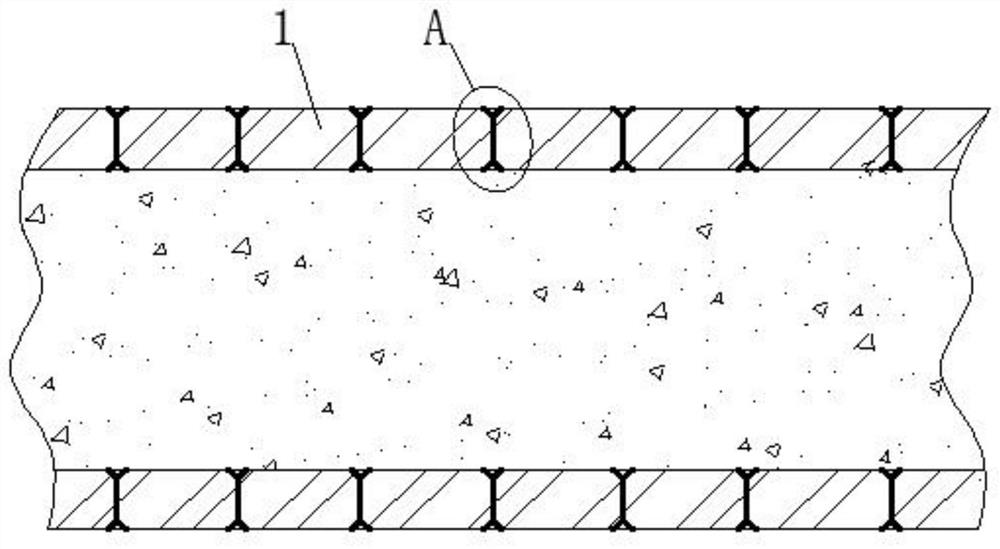

[0050] Please refer to Figure 1-2, a preparation method of the metal oxide layer on the electrolyte surface of a sodium battery, including the following

[0051] step:

[0052] S1. Mix the metal oxide and the sodium source according to the stoichiometric ratio, mix them evenly, put them in the gasification membrane shell for loose pressing, so as to pre-shape, and then program the temperature to the required temperature;

[0053] S2, then carry out the first calcination in an inert atmosphere for 1.5-4h to obtain a primary product; S3, remove the vaporization membrane shell of the primary product, and let it stand to cool down;

[0054] S4. After the first product is ground, the second calcination is carried out for 10-13h in an inert atmosphere, and the target metal oxide layer is obtained.

[0055] The temperature in S2 is 280-410°C, the temperature in S4 is 700-900°C, and the metal oxide in S1 is one or more oxides of Ni, Co, Mn, and Fe.

[0056] The specific steps of loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com