Double-hearth kiln for calcining lime by using low-calorific-value fuel and calcining method

A technology of calcining lime and double-chamber kiln, which is applied in the field of chemical building materials production, and can solve problems such as affecting economic benefits, inability to decompose limestone, and incomplete decomposition of limestone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

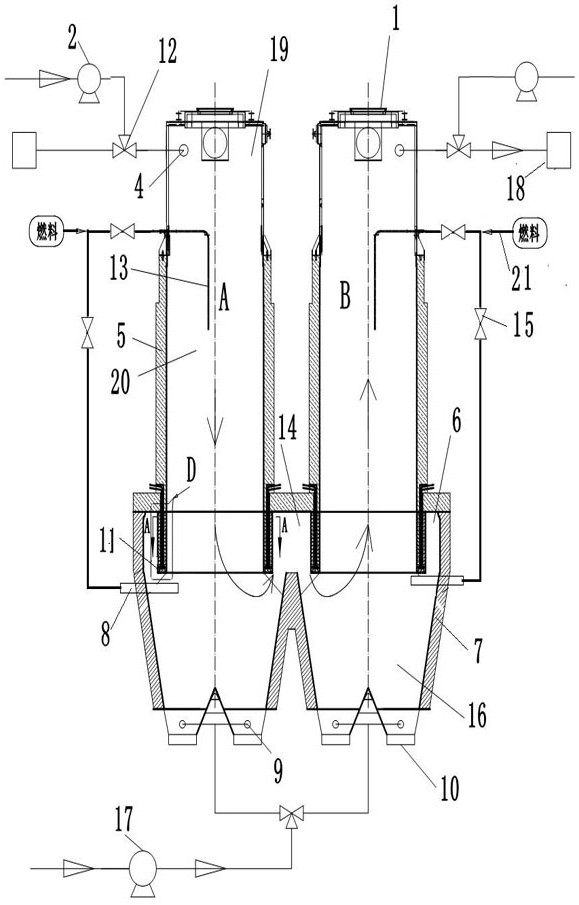

[0014] The invention provides a double-chamber kiln for calcining lime with low calorific value fuel, such as figure 1 As shown, it includes a double-chambered kiln body, feeding equipment, discharging equipment, air supply system, fuel pipeline 21 and exhaust gas discharge system 18, and a flue gas channel 14 is provided between the two kiln bodies. The double-chamber kiln has a hanging cylinder structure, and the kiln body is composed of an upper inner furnace wall 5 and a lower outer furnace wall 7, and the inner furnace wall is suspended on the outer furnace wall. The bottom of the inner furnace wall 5 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com