Box burner shaft kiln

A vertical kiln and box-type technology, which is applied in the field of calcining kilns for bulk materials, can solve the problems of long calcining time, poor sealing, flying dust, etc., to improve uneven heat distribution, improve uniformity and sealing , the effect of reducing dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

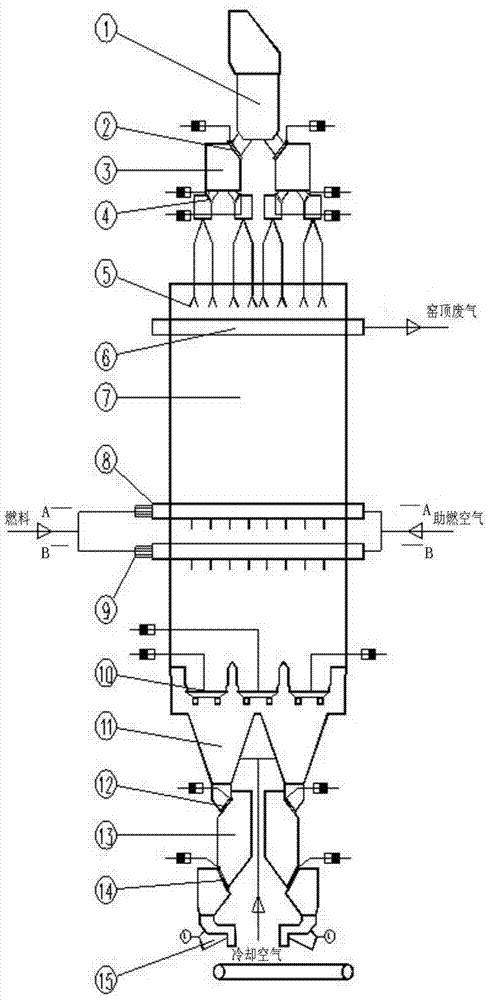

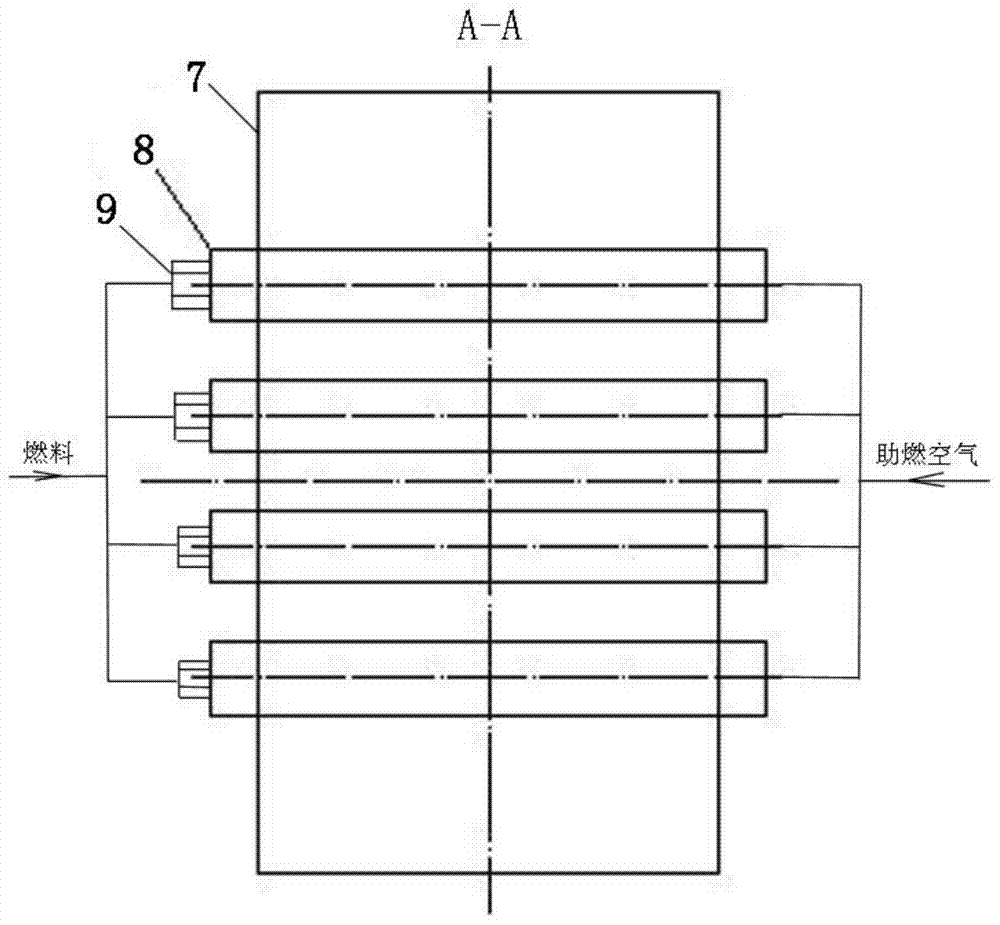

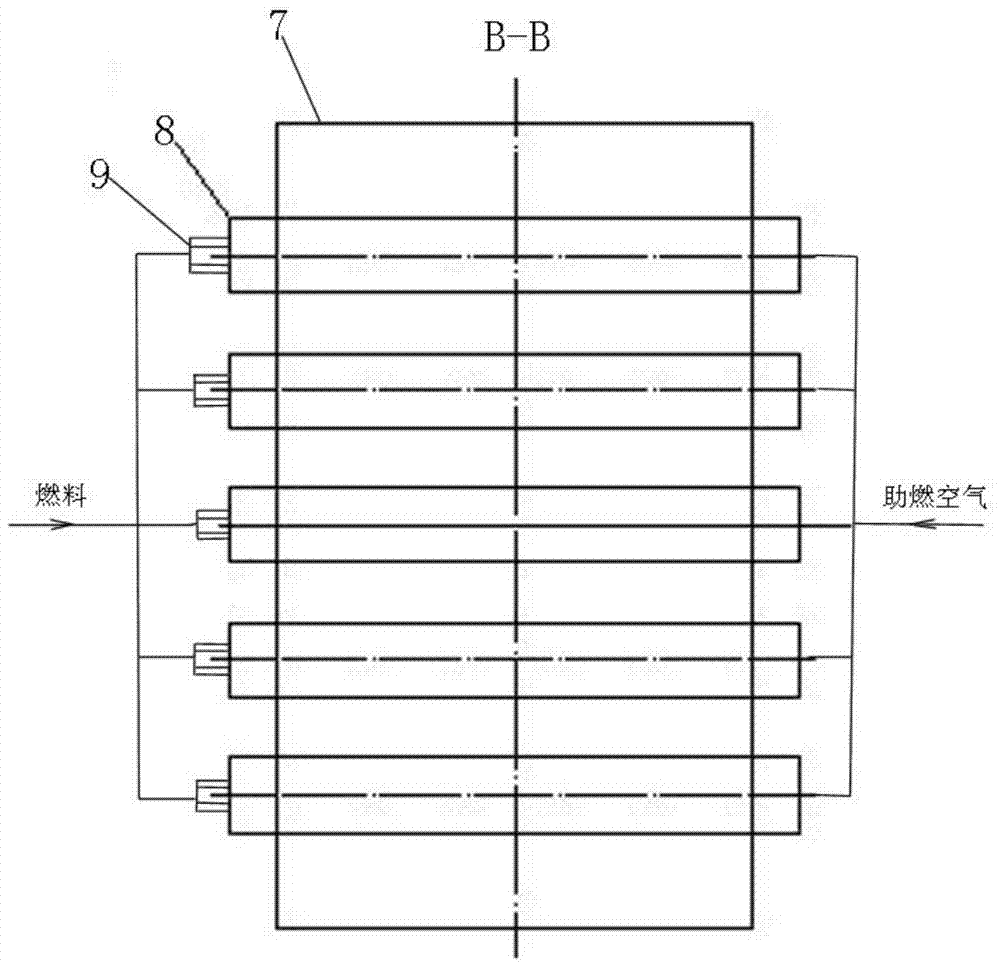

[0023] See figure 1 , is a structural representation of the present invention. The box-type burner vertical kiln of the present invention includes a kiln chamber 7, a kiln top exhaust device, a kiln top sealing feeding device and a kiln bottom sealing unloading device. The inside of the kiln chamber 7 is divided into preheating zone, calcining zone and cooling zone; the kiln chamber 7 at the lower part of the calcining zone is provided with at least two layers of box burners 8, and each layer of box burners 8 includes several burner boxes arranged in parallel horizontally, and the upper and lower two The layer burner boxes are arranged in a staggered manner; Figure 4 As shown, each burner box is provided with a plurality of fuel spray guns 9, and its fuel nozzles 17 are evenly arranged at the bottom of the burner box along the length direction;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com