Petroleum coke calcining device for prebaked anode

A technology of calcining device and pre-baked anode, which is applied in the fields of carbon preparation/purification, furnace, lighting and heating equipment, etc., can solve the problems of poor calcination effect of petroleum coke, etc., and achieve good calcination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

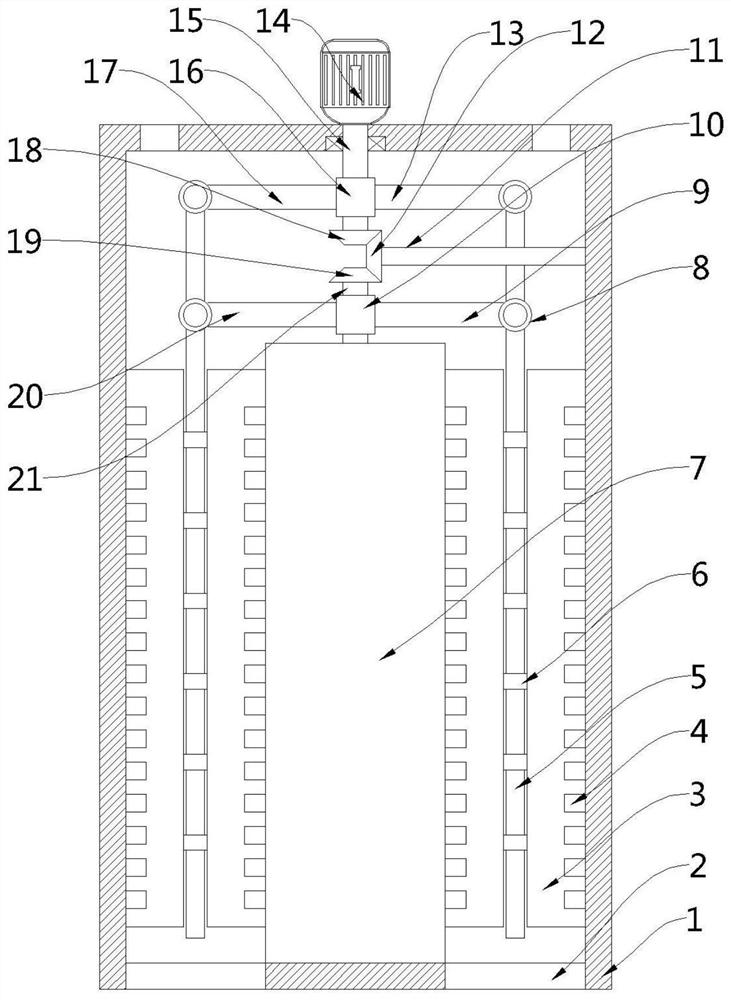

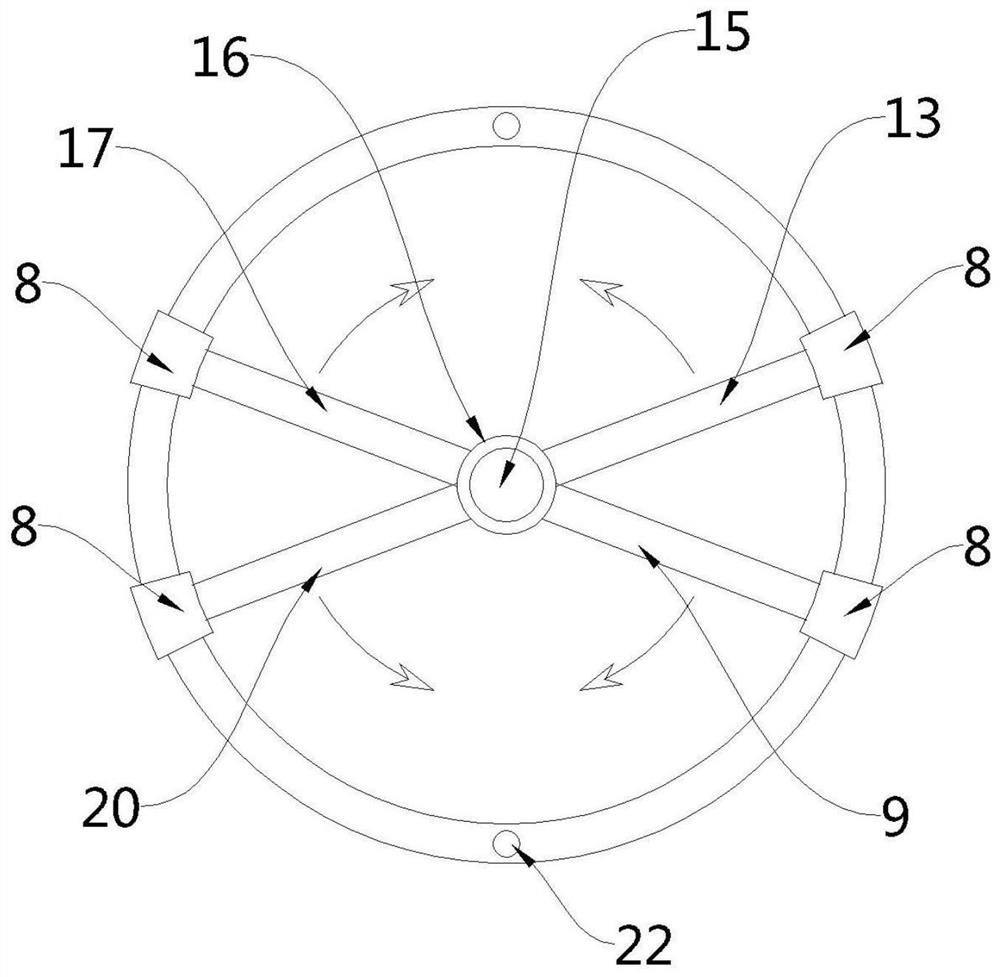

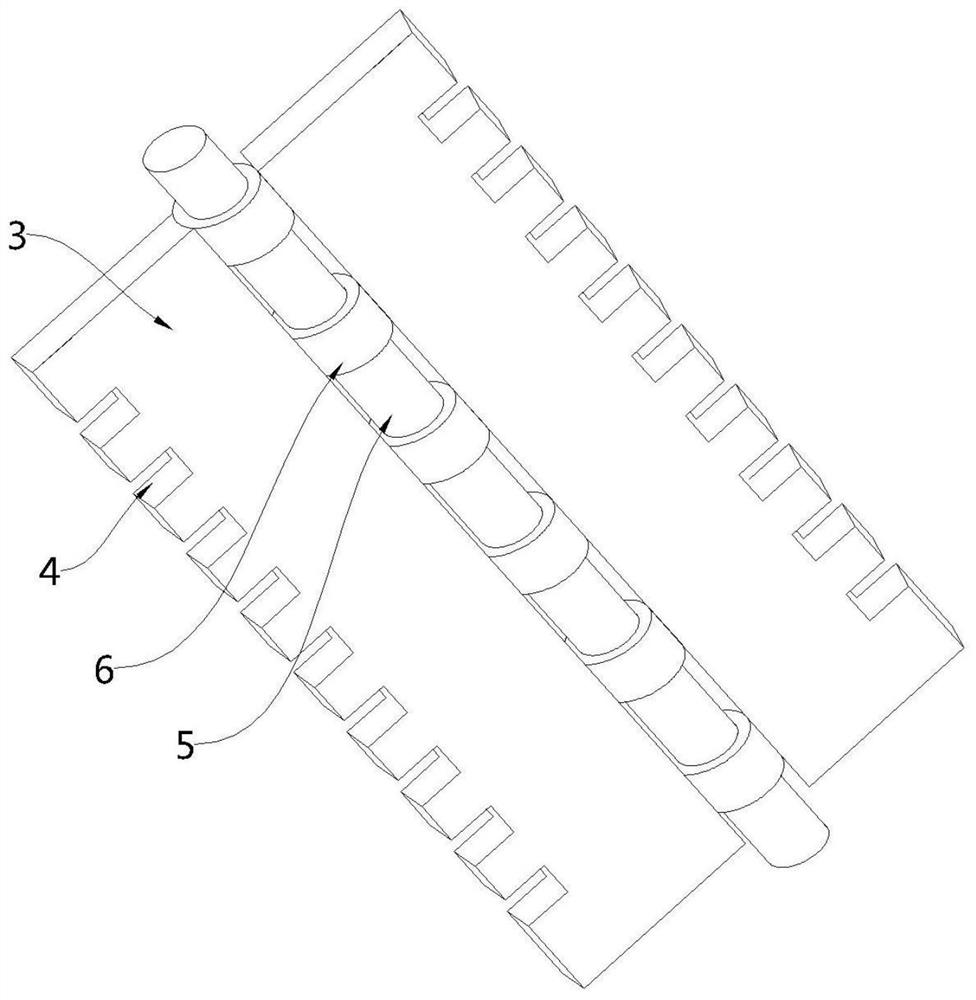

[0024] see Figure 1-3 , this embodiment provides a petroleum coke calcining device for prebaked anodes, including a calcining cylinder 1 and a central column 7 arranged inside the calcining cylinder 1, and an annular shape is formed between the calcining cylinder 1 and the central column 7 A calcining channel, the upper part of the calcining cylinder 1 is provided with a number of material inlets, the bottom of the calcining cylinder 1 is provided with a number of discharge ports 2, the inner wall of the calcining cylinder 1 and the outer wall of the central column 7 are provided with heating plates; the annular calcining channel There are four sets of stirring assemblies inside. Specifically, the stirring assemblies include transmission rods 5 vertically distributed inside the annular calcination channel and two groups of paddle plates 3 that are rotatably arranged on the transmission rods 5. The transmission assembly includes two sets of guide rings arranged above the centr...

Embodiment 2

[0034] see figure 1 and image 3 , a petroleum coke calcining device for prebaked anodes. Compared with Embodiment 1, the side of the shifting plate 3 far away from the transmission rod 5 in this embodiment is provided with a plurality of guide grooves 4, through which the guide grooves 4 The setting of the set makes the petroleum coke raw material move to the direction of the inner wall of the calcining cylinder 1 and the outer wall of the center column 7 by the shifting plate 3, and the petroleum coke raw material can flow to the other side of the shifting plate 3 through the material guide groove 4, thereby avoiding two groups of When the transmission rods 5 are close to each other, the corresponding shifting plate 3 will cause a greater extrusion effect on the petroleum coke raw material, thereby affecting the smooth movement of the two groups of transmission rods 5 .

[0035] In the embodiment of the present invention, four sets of stirring assemblies are arranged inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com