Energy-saving and environmentally-friendly kiln body and vanadium-nitrogen alloy high-temperature sintering kiln adopting energy-saving and environmentally-friendly kiln body

An energy-saving and environment-friendly kiln body technology, which is applied in the direction of furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of high unit energy consumption and poor operating conditions, and achieve low unit energy consumption, good operating conditions and lower temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

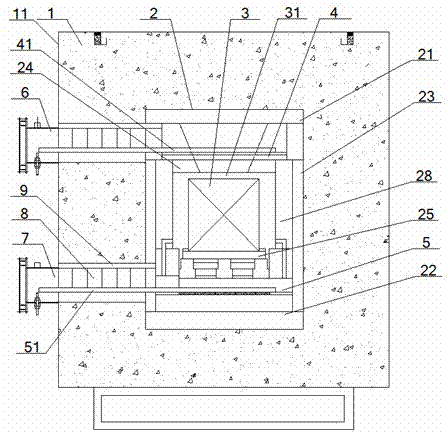

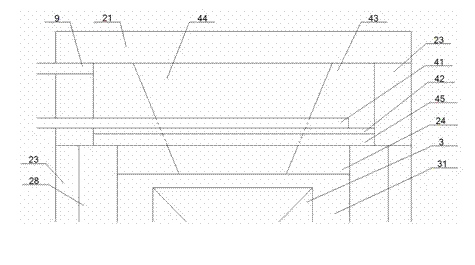

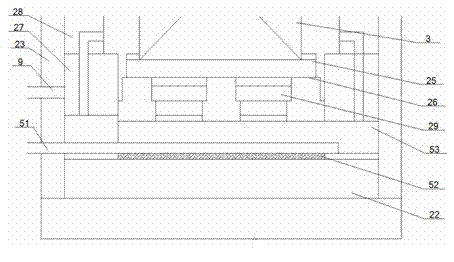

[0069] see figure 1 – Figure 4 , an energy-saving and environment-friendly kiln body, comprising a thermal insulation refractory layer 1, a calcining chamber 2, a graphite crucible 3, an upper horizontal heating chamber 4, a lower horizontal heating chamber 5, an upper sealing box 6 and a lower sealing box 7, the thermal insulation refractory layer 1 is surrounded by a furnace shell 11, and a calcining chamber 2 is arranged inside the thermal insulation refractory layer 1, and a kiln cavity 31 is arranged inside the calcining chamber 2, and a graphite crucible 3 is arranged inside the kiln chamber 31; the calcining chamber 2 includes a top plate 21. The bottom plate 22 and the side wall 23, the two ends at the bottom of the top plate 21 are connected to the two ends at the top of the bottom plate 22 through the side wall 23, the bottom of the graphite crucible 3 is connected to the top of the guide rail 26 through the push plate 25, The top of the graphite crucible 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com