Atmosphere-controllable high-speed rotary kiln

A rotary kiln and high-speed technology, applied in the field of rotary kilns, can solve the problems of limited angle between the kiln body and the horizontal plane, lack of temperature control devices to quickly raise and lower the temperature in the kiln, slow rotation speed, etc., to achieve good calcination effect, complete reaction, reduce The effect of experimental error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

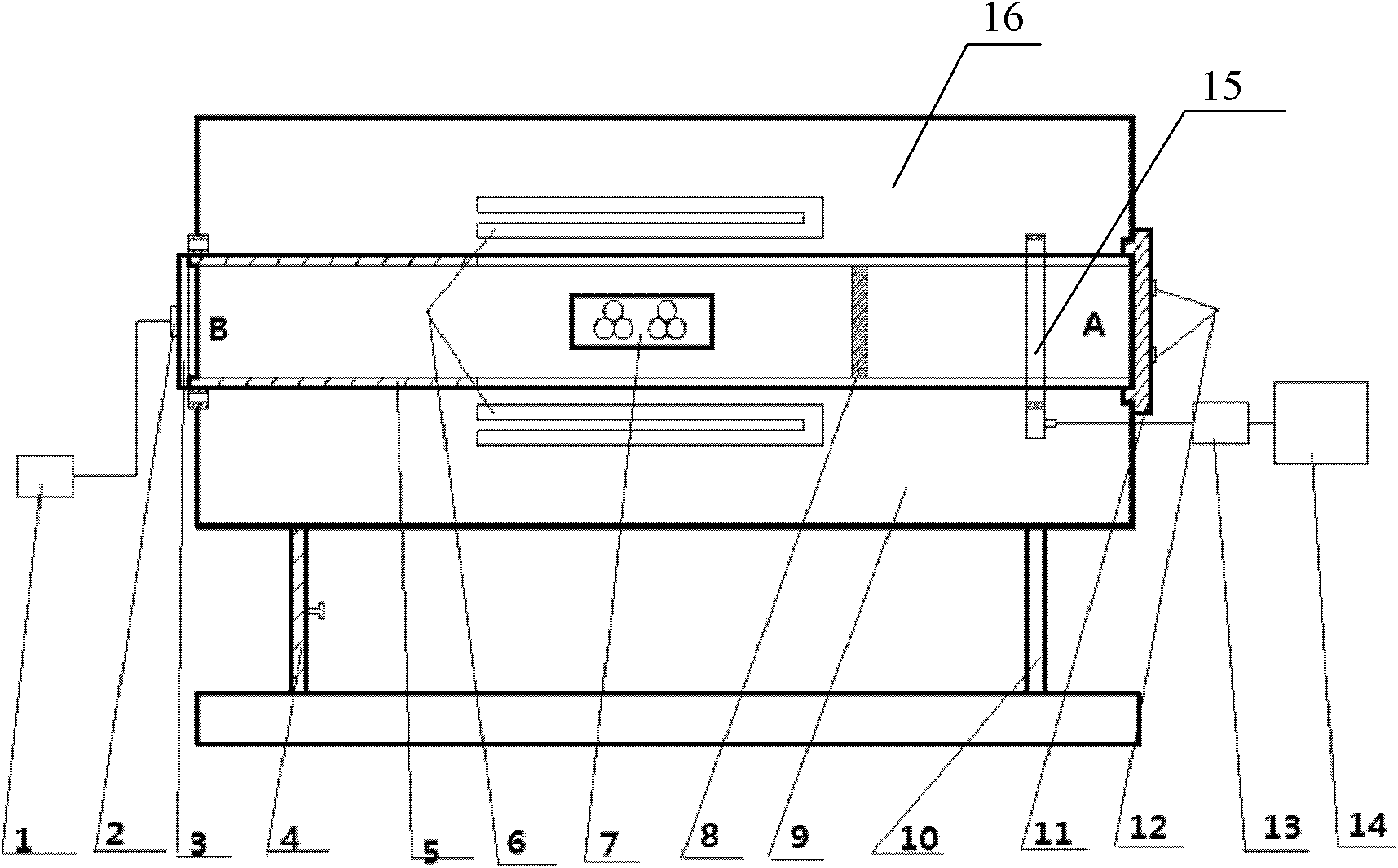

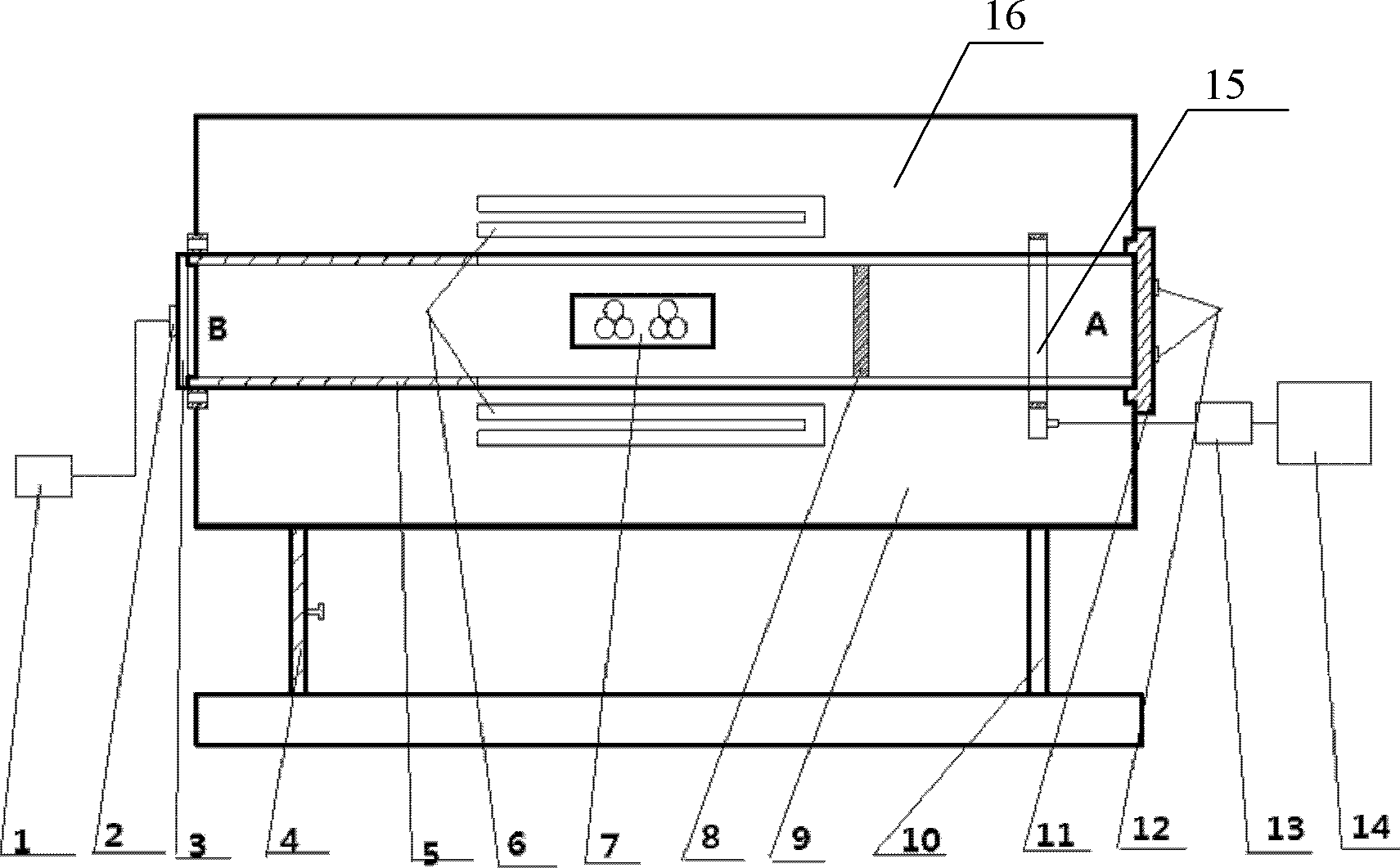

[0024] As shown in the accompanying drawings, a high-speed rotary kiln with controllable atmosphere includes a horizontal box body 9, in which a horizontal rotary furnace body 16 is used, and adjustable support rods 4 are respectively arranged under the two ends of the box body 9, Such as screw rods, etc., or an adjustable support rod 4 is provided under one end of the box body 9, and a fixed support rod 10 is provided at the other end. Manual adjustment of the adjustable support rod 4 can make the angle range between the rotary furnace body 16 and the horizontal plane be -5 °~5°, a transmission device 15 that can drive the furnace body to rotate is set outside the rotary furnace body 16. The transmission device 15 is connected to the motor 14 through the speed change system 13, and is driven by the motor 14. The speed change system 13 realizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com