System and method for achieving green denitration by means of dry process production process

A production process and denitration technology, which is applied in the system field of ammonia-free green denitration, can solve the problem of high cost increase, and achieve the effects of reducing coal consumption at the kiln head, simple construction and lowering production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

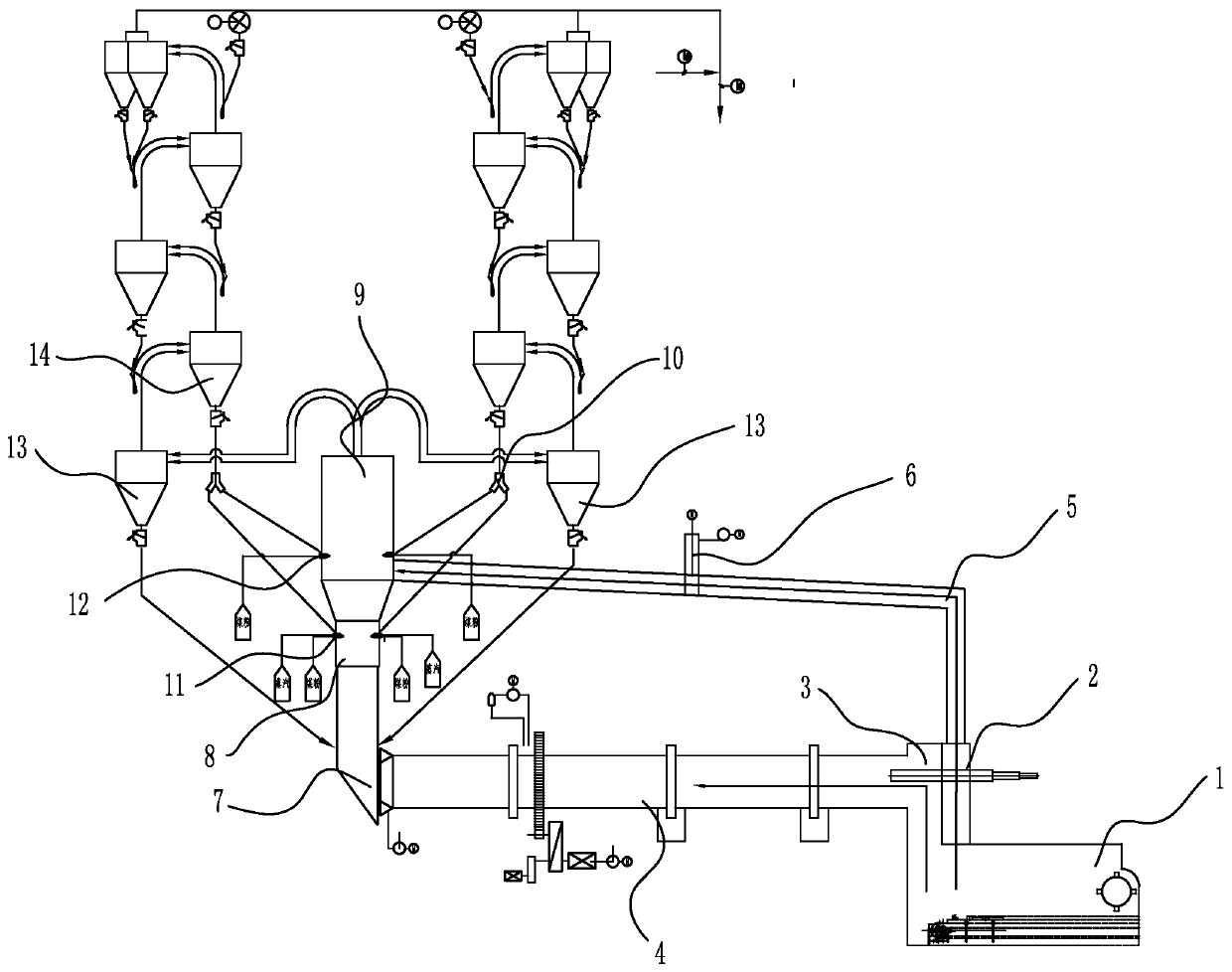

[0029] A system and method for realizing green denitrification by using a dry production process of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] Such as figure 1 As shown, a system for realizing green denitrification by using a dry production process of the present invention includes a multi-stage cyclone, a calciner 9, a kiln tail smoke chamber 7, a rotary kiln 4 and a grate cooler 1, and the lower part of the calciner 9 is A denitrification chamber 8 is provided, and the denitrification furnace 9 is provided with a spraying integrated device 12 for spraying coal powder, and the denitrification chamber 8 is provided with a spray denitrifier 11 for spraying steam and coal powder at the same time. The lower part of the chamber 8 is provided with a kiln tail smoke chamber 7, the kiln tail smoke chamber 7 is connected with the rotary kiln 4, and the grate cooler 1 of the kiln head of the rotary kiln 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com