Fluidizing calciner

A technology of boiling calcination and calcining furnace, which can be used in furnaces, fluidized bed furnaces, furnace types, etc., and can solve the problems of unsatisfactory combustion effect, inconvenient observation and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

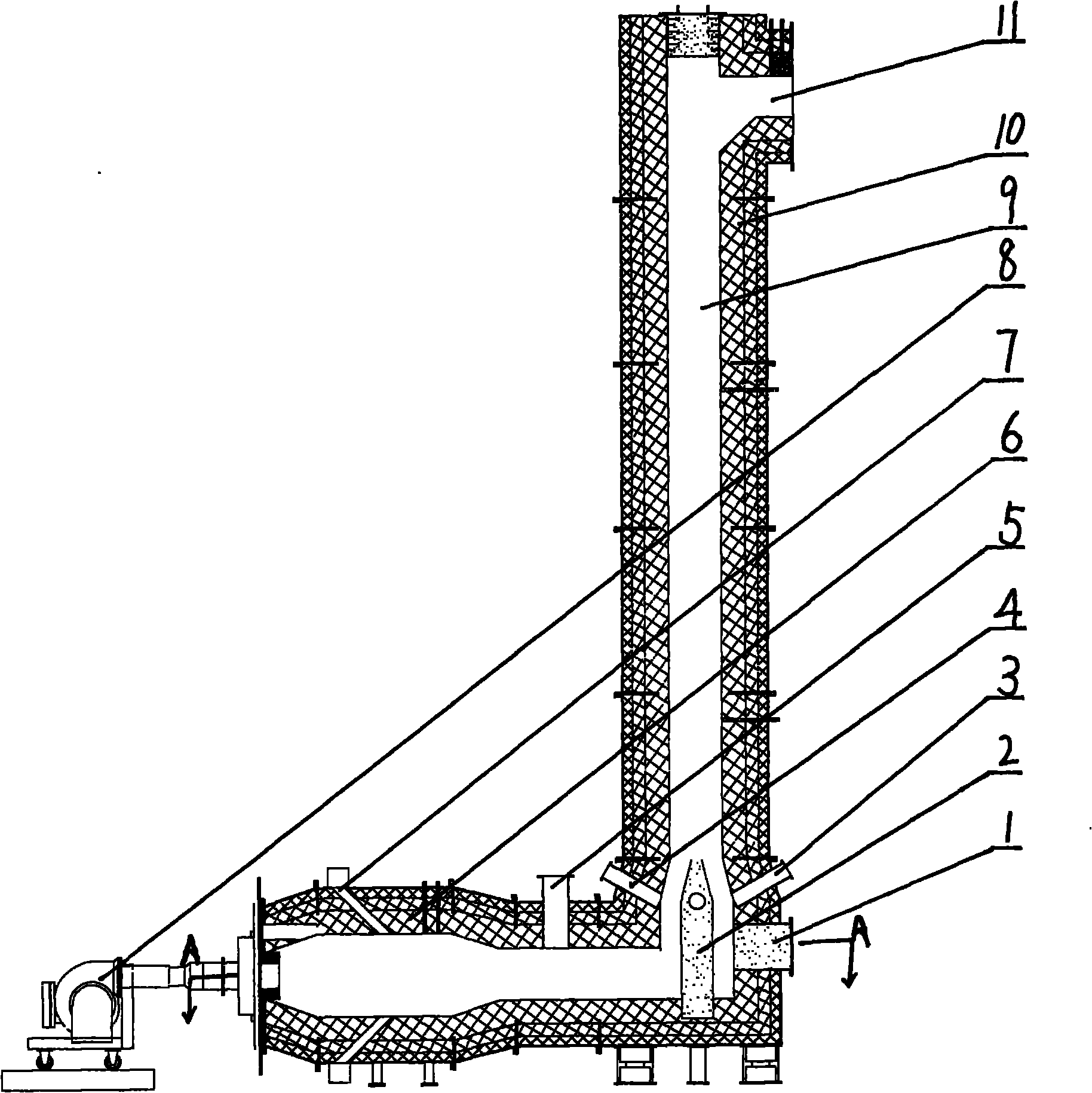

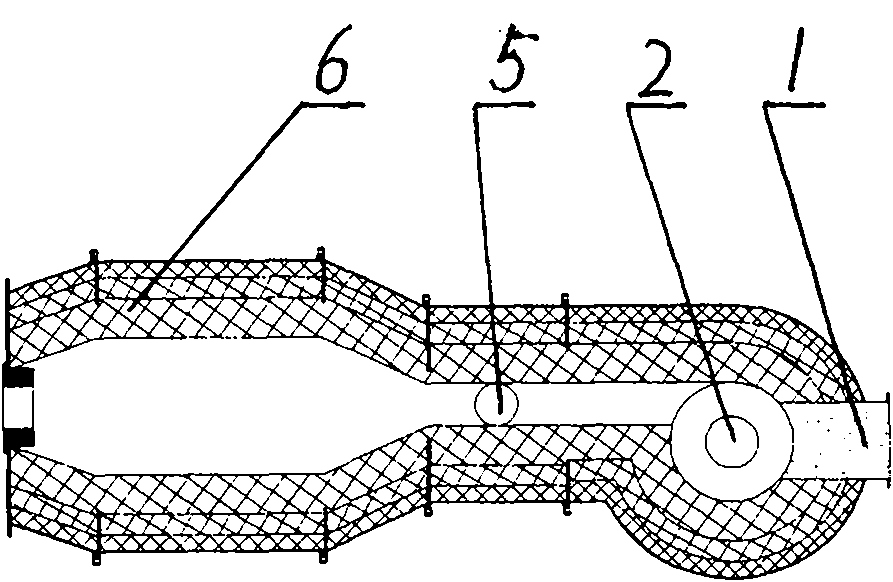

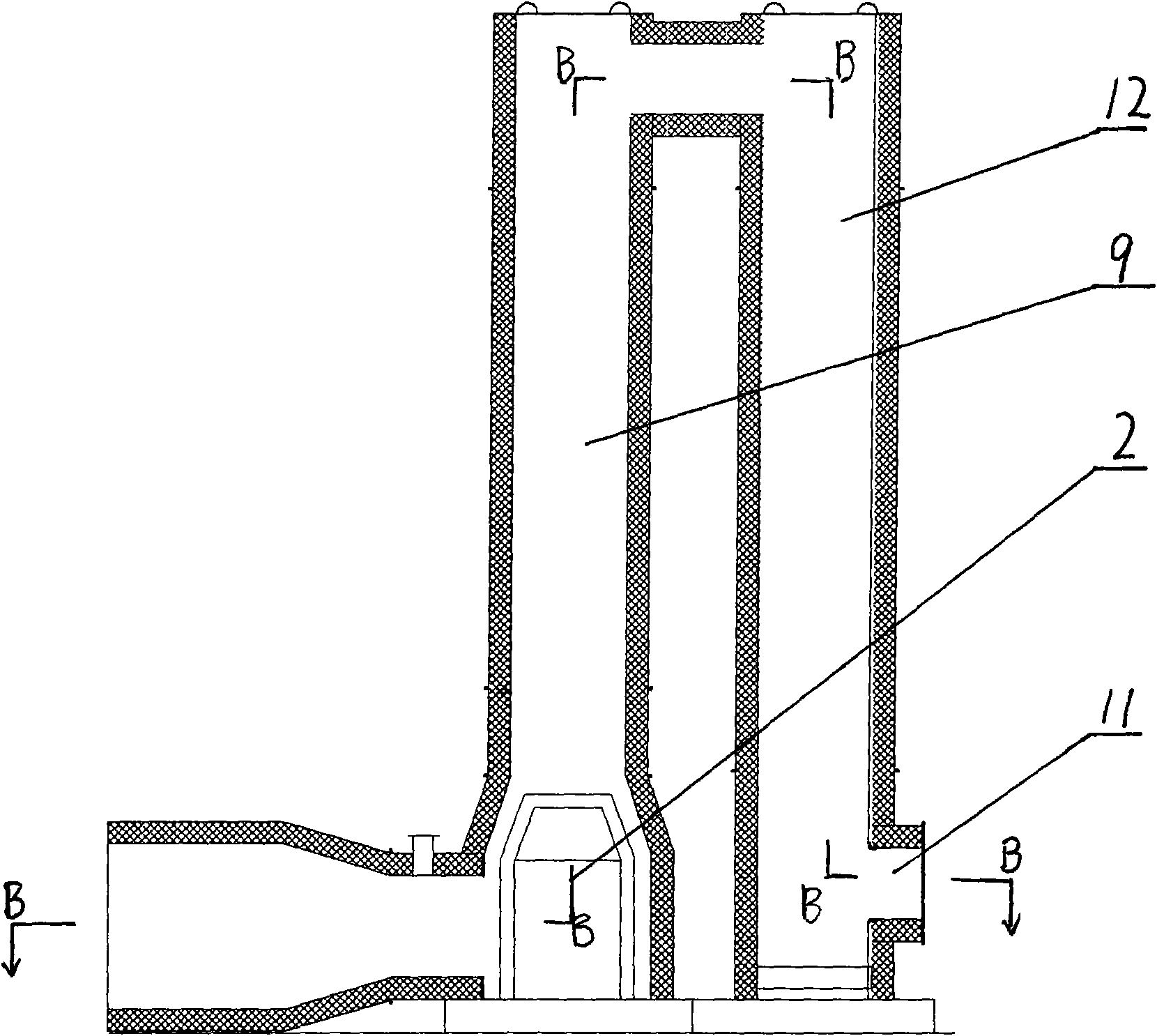

[0019] The present invention includes a calciner 10, the calciner 10 is composed of a combustion chamber 6 and a flue 9 with a discharge port 11 on the side of the combustion chamber 6, the combustion chamber 6 is connected with the burner 8, and the bottom of the flue 9 is a reverse flow Column 2, the side of the backflow column 2 is the backflow port 1, and the wall of the flue 9 above the backflow column 2 is respectively provided with an observation hole 3 and a feed port 4; the tail of the combustion chamber 6 is provided with a high-temperature feeding pipe 5 .

[0020] The discharge port 11 can also be connected with the secondary flue 12, and the bottom of the secondary flue 12 is provided with a discharge port 11. The auxiliary flue 12 can make the material burn more fully.

[0021] A course of action of the present invention is illustrated below in conjunction with accompanying drawing:

[0022] After the material to be calcined is mixed with the high-temperature g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com