Device for preparing light calcined magnesia and collecting carbon dioxide

A technology of lightly burning magnesium oxide and carbon dioxide, which is applied in the fields of combined devices, chemical instruments and methods, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

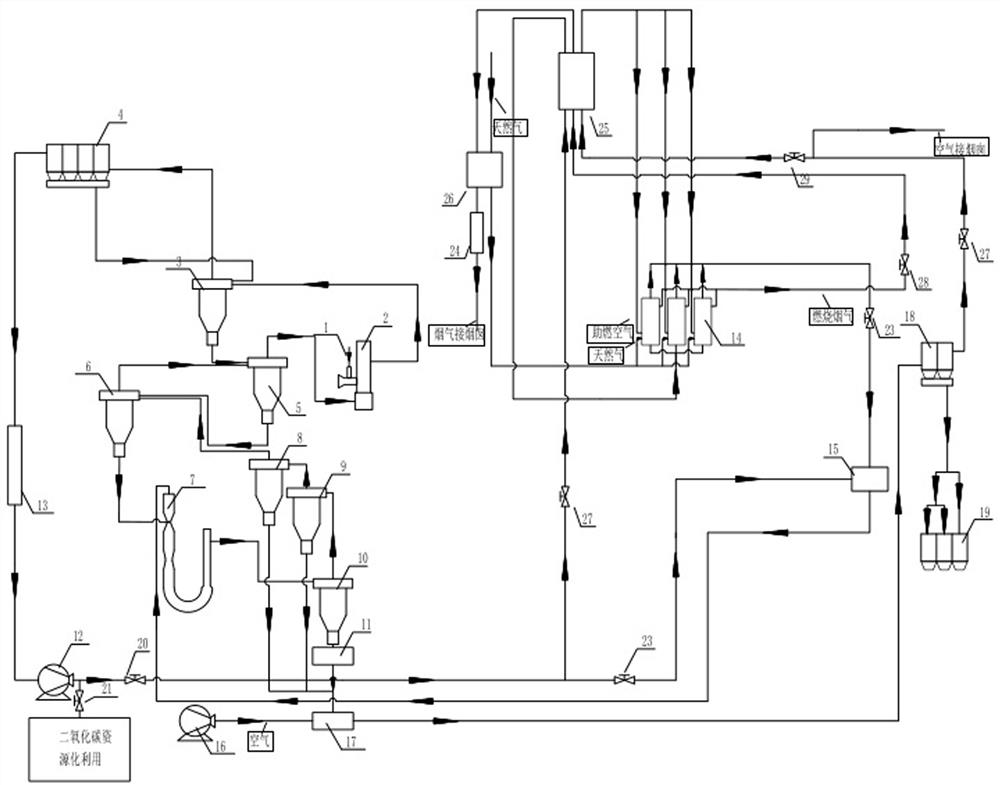

[0042] Such as figure 1 At any time, 1.12t of wet magnesite material after flotation is put into the flash dryer 2 through the feeder 1 per hour. h. Pass the dried magnesite powder into the first-level preheating cyclone device 3, the second-level preheating cyclone device 5, and the third-level preheating cyclone device 6 successively for preheating, and after the first-level preheating cyclone device 3, the magnesite The temperature of the magnesite powder is preheated to 150°C, the temperature of the magnesite powder is preheated to 420°C after the second stage preheating cyclone device 5, and the temperature of the magnesite powder is preheated after the third stage preheating cyclone device 6 When heated to 550°C, the pyrolysis temperature of magnesite is 400-500°C. When the magnesite is preheated by the preheating device, 30% of the input amount of magnesite has been decomposed, and the remaining 70% is calcined by jet pulse entrained flow bed The furnace decomposes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com