Powder oscillation kiln

A kind of kiln and powder technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., to achieve the effect of labor saving, reliable temperature control and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

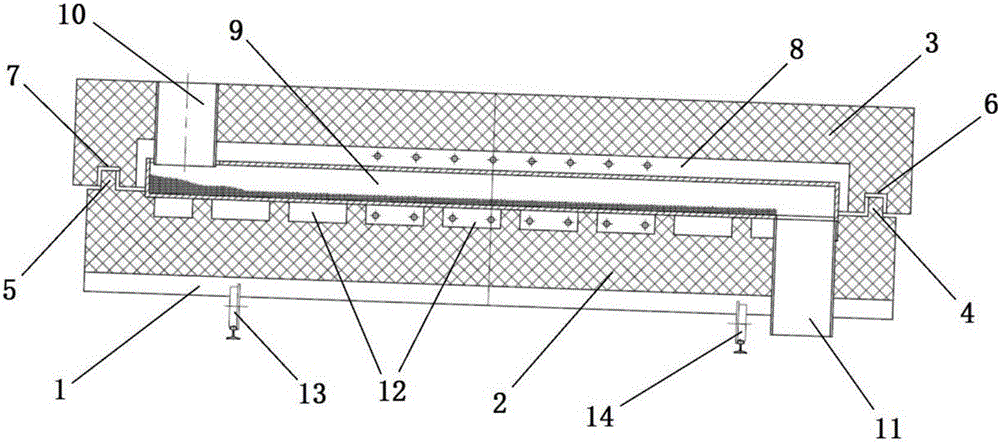

[0032] A powder oscillating kiln, including a base plate 1, a base 2, an upper cover 3, a first strip-shaped protrusion 4, a second strip-shaped protrusion 5, a first strip-shaped groove 6, and a second strip-shaped groove 7 , cavity 8, refractory pipe 9, feed pipe 10, discharge pipe 11, vibrating motor 12, first bracket 13, second bracket 14, wherein the base 2 is fixedly connected to the base plate 1, and the upper surface of the base 2 is on both sides There are first strip-shaped protrusions 4 and second strip-shaped protrusions 5 respectively, and both sides of the lower surface of the upper cover 3 have first strip-shaped grooves 6 and second strip-shaped grooves 7 respectively, and the first strip-shaped protrusions 4 matches the shape of the first strip-shaped groove 6, the second strip-shaped protrusion 5 matches the shape of the second strip-shaped groove 7, and the upper cover 3 passes through the first strip-shaped groove 6 and the second strip-shaped groove. The g...

Embodiment 2

[0039] A powder oscillating kiln, including a base plate 1, a base 2, an upper cover 3, a first strip-shaped protrusion 4, a second strip-shaped protrusion 5, a first strip-shaped groove 6, and a second strip-shaped groove 7 , cavity 8, refractory pipe 9, feed pipe 10, discharge pipe 11, vibrating motor 12, first bracket 13, second bracket 14, wherein the base 2 is fixedly connected to the base plate 1, and the upper surface of the base 2 is on both sides There are first strip-shaped protrusions 4 and second strip-shaped protrusions 5 respectively, and both sides of the lower surface of the upper cover 3 have first strip-shaped grooves 6 and second strip-shaped grooves 7 respectively, and the first strip-shaped protrusions 4 matches the shape of the first strip-shaped groove 6, the second strip-shaped protrusion 5 matches the shape of the second strip-shaped groove 7, and the upper cover 3 passes through the first strip-shaped groove 6 and the second strip-shaped groove. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com