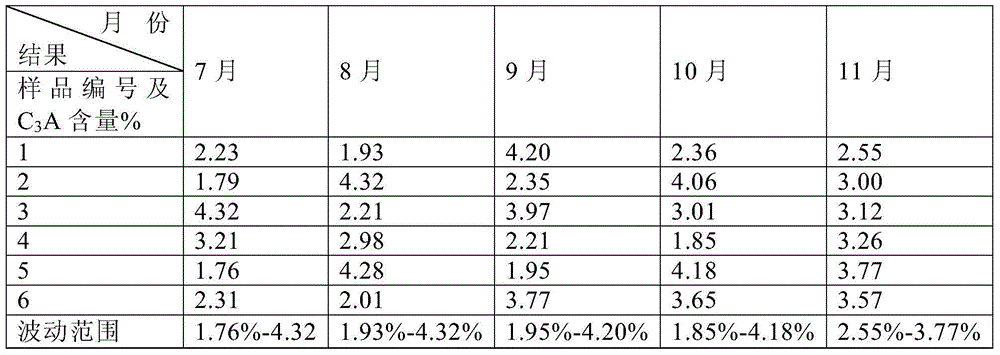

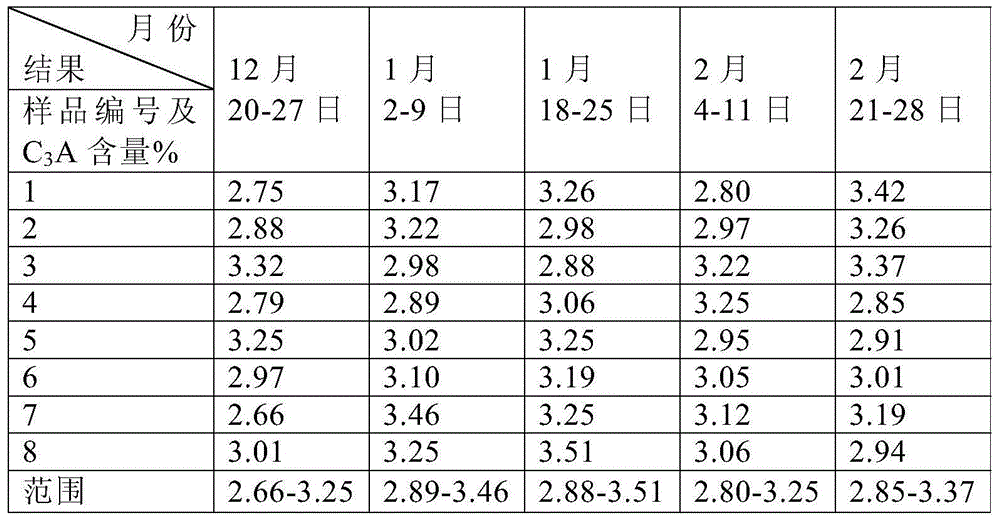

Stability control process for C3A content of road clinker discharged from kiln

A technology of stable control and clinker, which is applied in the field of stable control of C3A content in clinker on the way out of the kiln, can solve the problems of unreasonable ratio, unstable quality and large mud content, and achieves reasonable ratio and improved High calcination quality and high mud content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

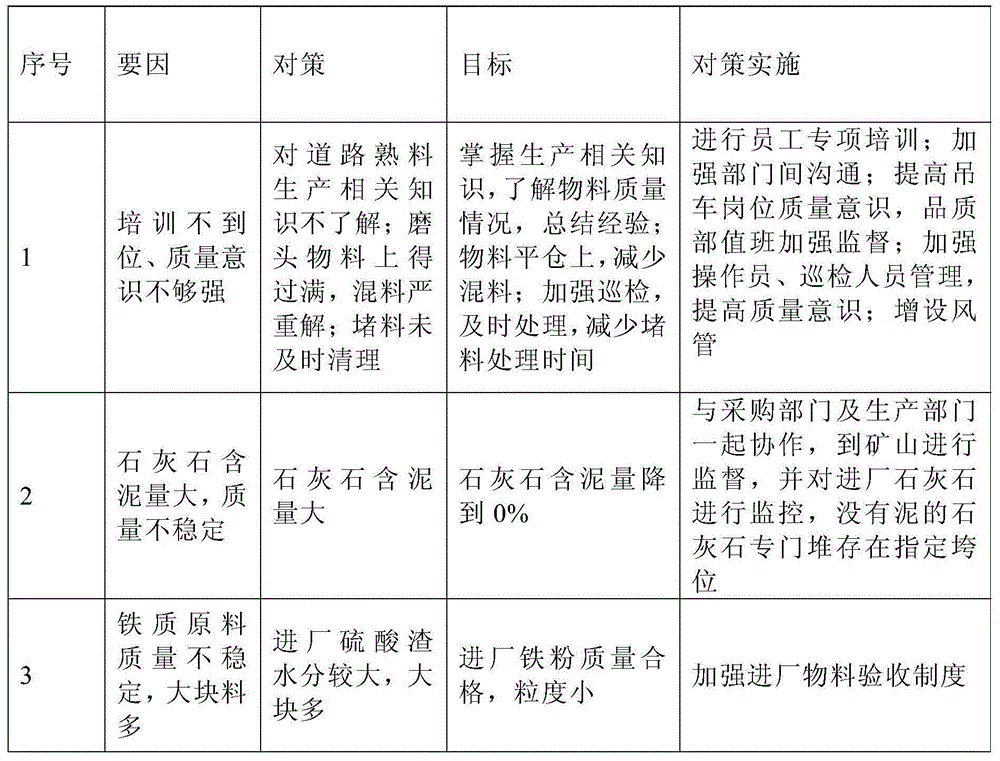

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0038] According to an embodiment of the present invention, a process for stably controlling the content of C3A in the kiln road clinker is provided, including:

[0039] a. When the material is closed, the mixing is reduced; the road clinker is cleaned and dried after cleaning to reduce the mud content; step a also includes:

[0040] Before the limestone enters the factory, the mud content of the limestone is controlled by inspecting CaO, SiO2 and silicon oxide according to on-site sampling inspection;

[0041] During the production of road clinker, the limestone shall be confirmed in each shift, and samples shall be taken for inspection and analysis;

[0042] Strengthen on-site monitoring, and inspect the incomin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com