Lime kiln device adopting circulating hot air

A heating device and hot air technology, which is applied in the field of lime production and lime kiln, can solve the unsolved common technical problems of gas fired kilns, and can not be widely used, so as to improve the activity of lime products, shorten the calcination time, and improve the heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

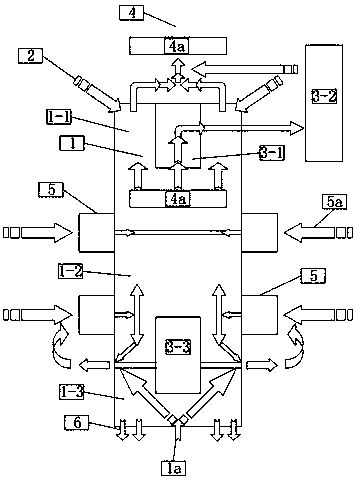

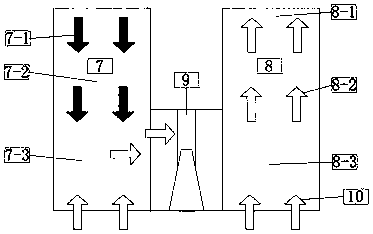

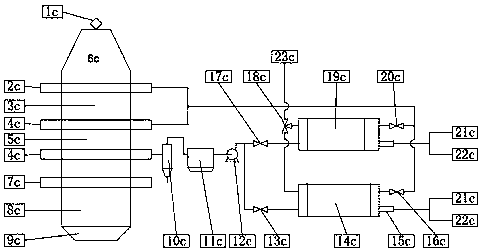

[0049] Figure 5 Shown is a typical case and working principle diagram of the lime kiln system using circulating hot air involved in the present invention, in which 100-kiln body, 103-preheating section, 104-calcining section, 105-cooling section, 101-feeding Mechanism, 102-discharge mechanism, 200-heating furnace group, 201-heat exchanger, 202-gas fuel, 203-combustion air, 204-heating furnace flue gas, 205-waste cooling air after heat exchange, 300 cooling fan , 301-waste cooling air dust collector, 302-purifying waste cooling air, 500-dust collector, 400-circulating hot air, 401-circulating fan, 402-discharging waste mixed air,

[0050] A lime kiln device using circulating hot air, including a kiln body 100 and a heating device, wherein the kiln body 100 includes from top to bottom: a feeding mechanism 101, a preheating section 103, a calcining section 104, a cooling section 105 and a discharging mechanism 102, the mineral material enters the kiln body 100 from the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com