Novel feeding device for decomposing furnace for cement kiln

A technology of feeding device and decomposition furnace, which is applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of increasing energy consumption, and it is difficult for materials to disperse powder, etc., and achieve the effect that is beneficial to calcination quality and energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

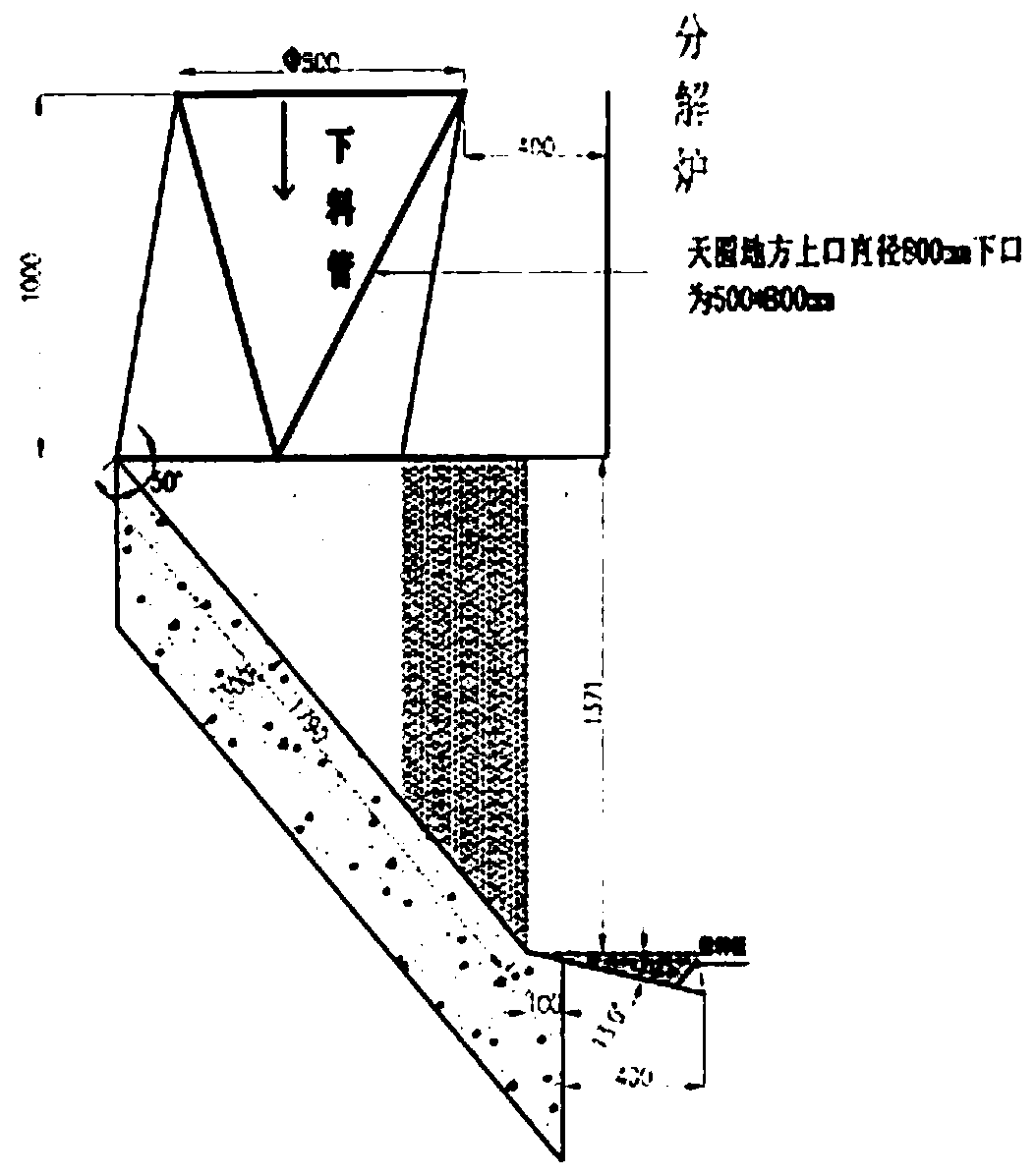

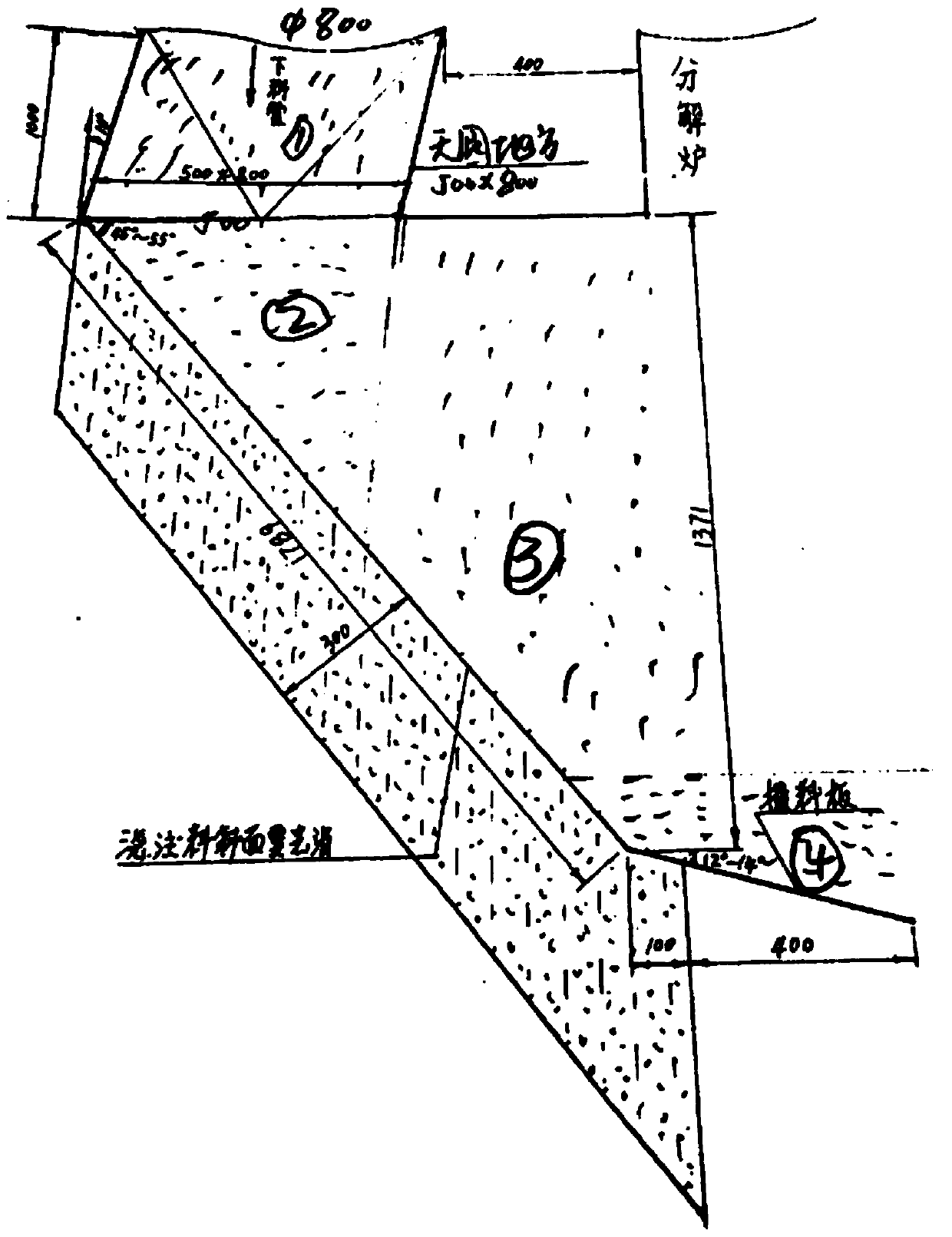

[0016] Such as Figure 1-3 As shown, the invention discloses a novel feeding device for a cement kiln calciner.

[0017] The area Ⅰ1 on the upper part of the feed end adopts a rectangular feed inlet. When the material enters this area, the material changes from cylindrical to rectangular with a flat material curtain and enters the area Ⅱ2 of the device. The feeding section of the device area Ⅰ1 adopts an outward slope method. It is to ensure that all materials enter the area II2 of the device.

[0018] The area II2 of the device is to disperse the viscous material from the upper stage and properly reduce the flow rate of the material. The area II2 is located directly below the bottom feed port of the area I1.

[0019] When the area III3 of the device introduces the material into the area IV4 of the device at an appropriate angle and flow rate, the material is dispersed for the second time; the area III3 is located below the area II2, and is located on the same slope as the ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com