Method for fabricating alkali proof glassbeads and siln for production

A production method and technology of glass spheres, applied in glass production, glass molding, glass furnace equipment, etc., can solve the problems of crystallization devitrification, high kiln pressure, and high energy consumption, so as to reduce raw material consumption and production cost , The effect of melting temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment takes the preparation of the required mixture for every 100kg of alkali-resistant glass balls produced as an example: the amount of each raw material and auxiliary material is respectively: 57.0kg of quartz sand, wherein: SiO 2 ≥99.0%, Fe 2 o 3 2 o 3 2 65%, TiO 2 2 o 3 2 87%, ZrO 2 >1.5%, Al 2 o 3 2 2 o 3 2 1.8kg of 94% fluorite, 23.5kg of soda ash with a purity of 99.6%, and 6.5kg of potassium nitrate with a purity of 94.0%. Each component is the powder that passes through a 40-mesh sieve after crushing.

[0020] Mix potassium nitrate, fluorite, rutile and other raw materials and auxiliary materials respectively into two kinds of initial mixing materials, and then alternately send them into the mixer and mix them evenly; finally add 3kg of clear water, continue stirring for 3 minutes, and then discharge;

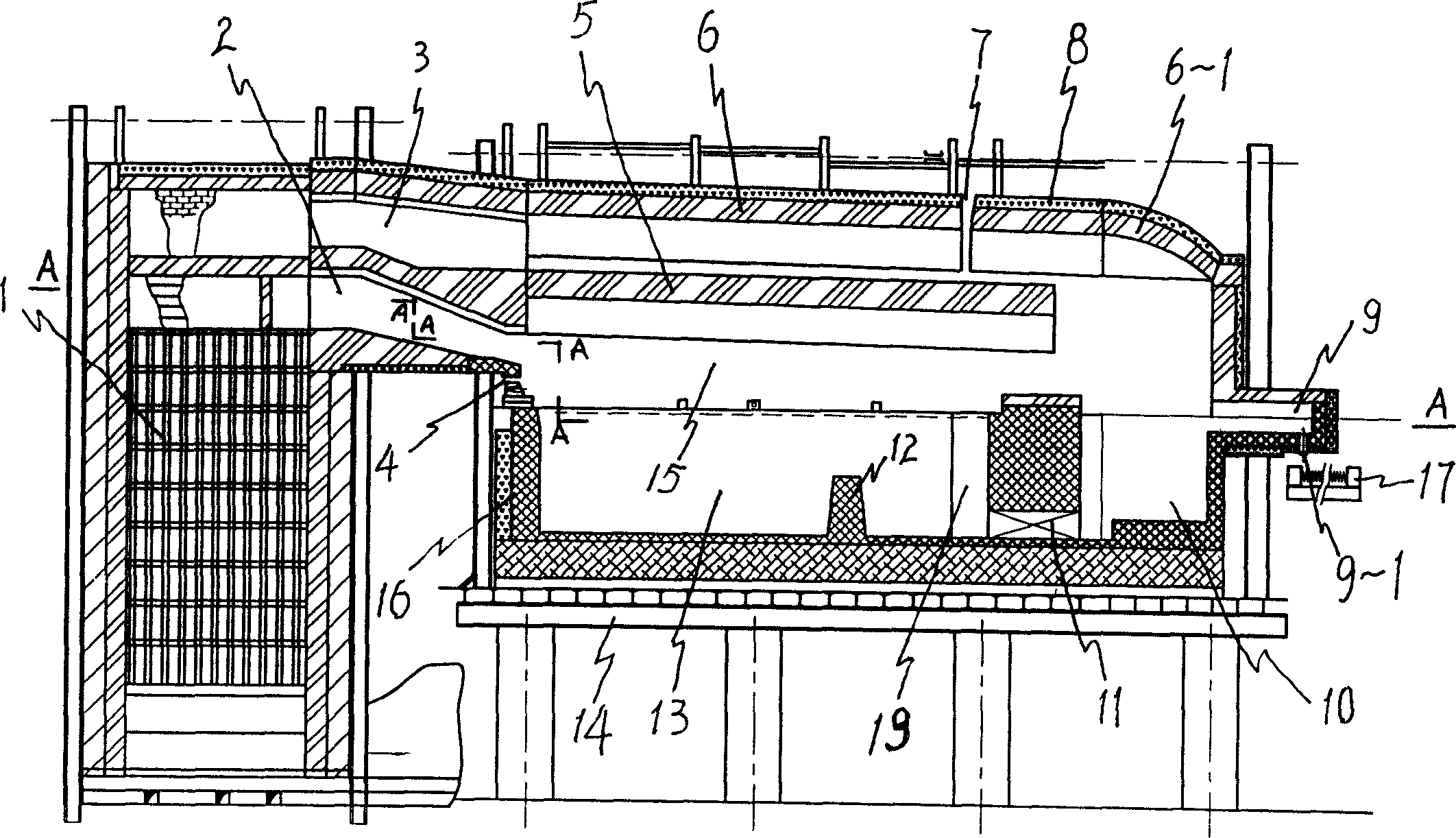

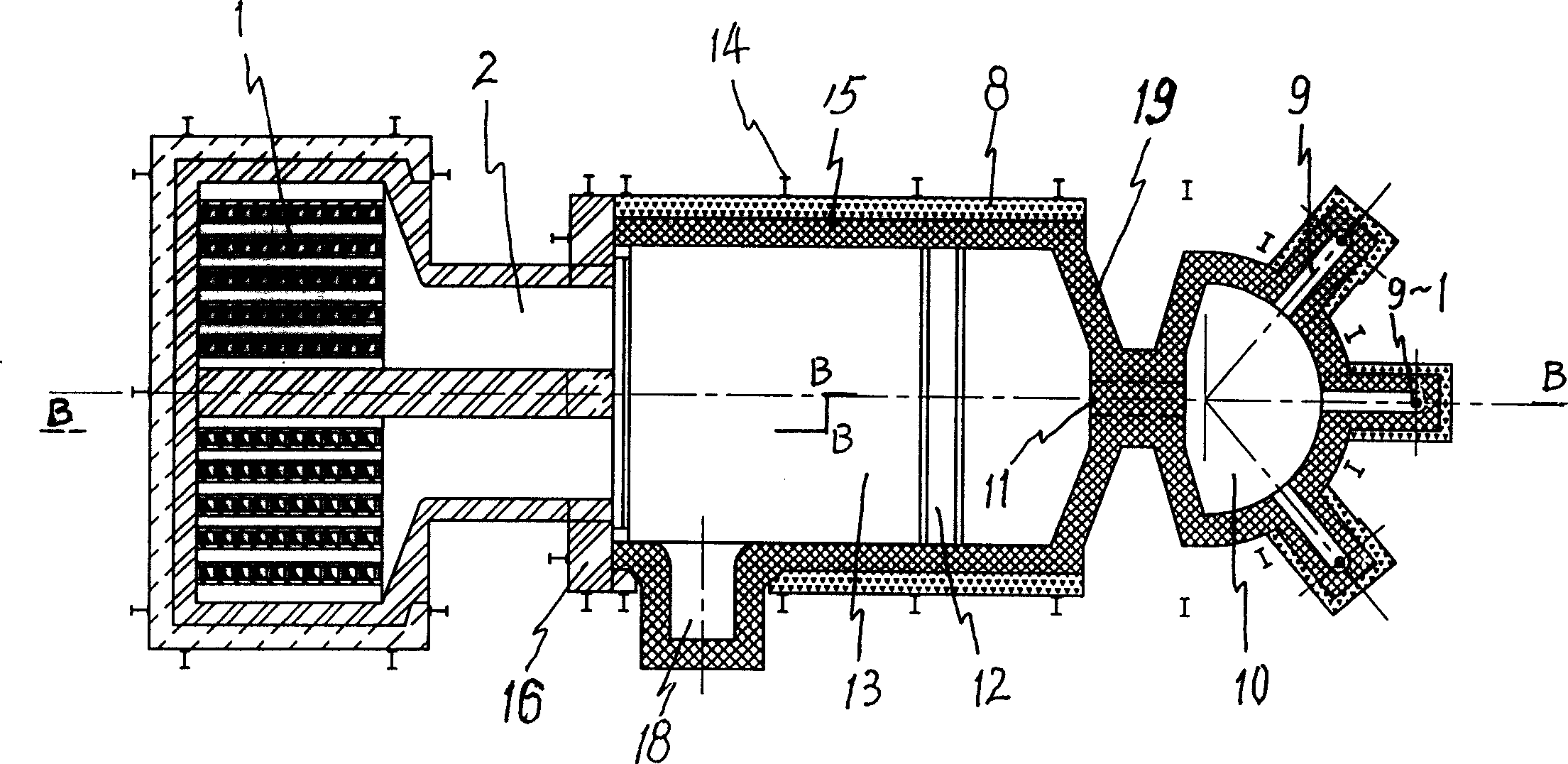

[0021] The mixed materials that have been prepared successively are fed into the melting pool 13 of the Shuanglong kiln through the feeder t...

Embodiment 2

[0024] When the chemical composition of each raw material and auxiliary material in embodiment 1 is constant, produce every 100kg glass ball, take by weighing 53.7kg quartz sand, 32.5kg zircon sand, 7.1kg rutile, 7.45kg calcite, 1.9kg fluorite, 28kg soda ash And 6.5kg potassium nitrate, be mixed with mixed powder, under the processing condition of embodiment 1, can produce containing ZrO 2 17.0% alkali-resistant glass balls.

Embodiment 3

[0026] When according to the raw material composition in embodiment 1, take by weighing respectively by producing 100kg glass ball: quartz sand 45.3kg, zircon sand 22.4kg, rutile 5.3kg, calcite 4.7kg, fluorite 1.5kg, soda ash 19.5kg, potassium nitrate 4.6kg kg, after making mixed powder, add 30kg of clinker with similar composition to the glass ball to be produced, and melt it at a temperature of 1610°±10°C to obtain ZrO-containing 2 Alkali-resistant glass balls around 14.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com