Cast ceramsites as well as manufacture method and application thereof

A technology of ceramsite and granules, which is applied in the direction of casting molding equipment, casting molds, manufacturing tools, etc., can solve the problems of increasing casting costs, high energy consumption, and increasing costs, so as to reduce production costs, make environmental protection easier, and benefit costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

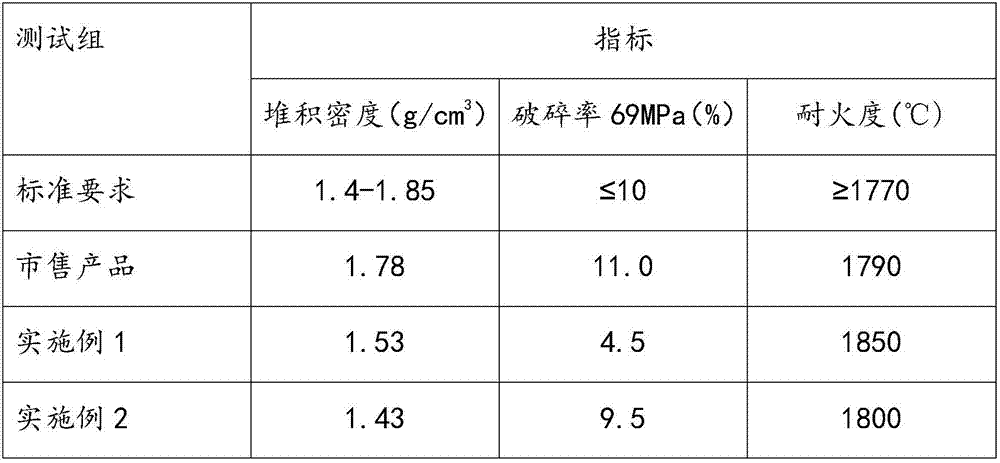

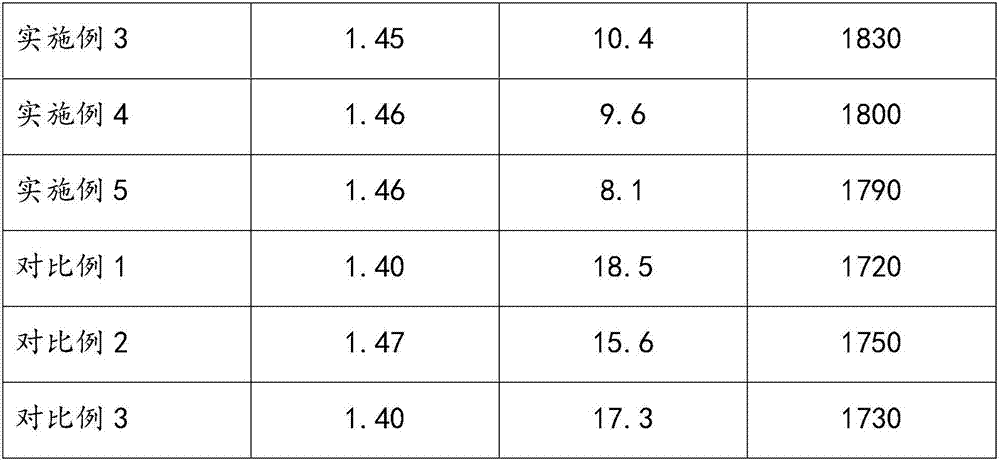

Examples

preparation example Construction

[0037] The preparation method of casting ceramsite of the present invention can specifically refer to as follows:

[0038] (a) Take an appropriate amount of bauxite clinker, kaolin and bauxite, and pulverize; preferably, take bauxite third-grade clinker, kaolin and third-grade bauxite respectively;

[0039] (b) according to the ratio of raw materials as mentioned above, take appropriate amount of pulverized bauxite clinker, kaolin, and bauxite as raw materials respectively, and mix and homogenize;

[0040] Preferably, in the present invention, cast ceramsite is continuously produced in multiple batches, therefore, in the present invention, the mixing and homogenization is to mix the raw materials mixed in multiple batches and stand still, and then grind, so as to carry out mixing and homogenization. change;

[0041] (c) Grinding the homogenized mixed raw materials, preferably, the grinding is multiple times of grinding, for example, 2, 3 or more times of grinding; then perfor...

Embodiment 1

[0051] (1) Take an appropriate amount of bauxite third-grade clinker, kaolin and third-grade bauxite respectively, and pulverize;

[0052] (2) According to the percentage by weight: 25% of bauxite third-grade clinker, 25% of kaolin and 50% of third-grade bauxite, respectively weigh the appropriate amount of pulverized bauxite third-grade clinker, kaolin and third-grade bauxite soil, and mix and homogenize;

[0053] (3) After grinding the mixed raw material after mixing and homogenizing, carry out heavy rot homogenization;

[0054] (4) After atomizing the water, mix it with the mixed raw material after sinking and rot homogenization, agglomerate and granulate during rotation, then sieve and dry the prepared particles, and perform surface polishing treatment, and then surface treatment Homogenization of particle storage;

[0055] Wherein, the mass gram of water used for atomization is 15% of the mass gram of the mixed raw material after heavy rot homogenization;

[0056] (5) ...

Embodiment 2

[0058] (1) Take an appropriate amount of bauxite grade 4 clinker, kaolin and grade 3 bauxite respectively and pulverize them;

[0059] (2) According to percentage by weight: 25% of bauxite grade 4 clinker, 25% of kaolin and 50% of grade 3 bauxite, respectively weigh the bauxite grade 4 clinker, kaolin and grade 3 bauxite after appropriate amount of crushing soil, and mix and homogenize;

[0060] (3) After grinding the mixed raw material after mixing and homogenizing, carry out heavy rot homogenization;

[0061] (4) After atomizing the water, mix it with the mixed raw material after sinking and rot homogenization, agglomerate and granulate during rotation, then sieve and dry the prepared particles, and perform surface polishing treatment, and then surface treatment Homogenization of particle storage;

[0062] Wherein, the mass gram of water used for atomization is 15% of the mass gram of the mixed raw material after heavy rot homogenization;

[0063] (5) The stored and homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com