Castable refractory for high-precision aluminum alloy melt external refining and using method

A refractory castable and out-of-furnace refining technology, applied in the field of refractory materials, can solve the problems of high price, unacceptable to users, and inability to meet refining high-precision aluminum alloys, etc., and achieves the effect of large adaptability and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

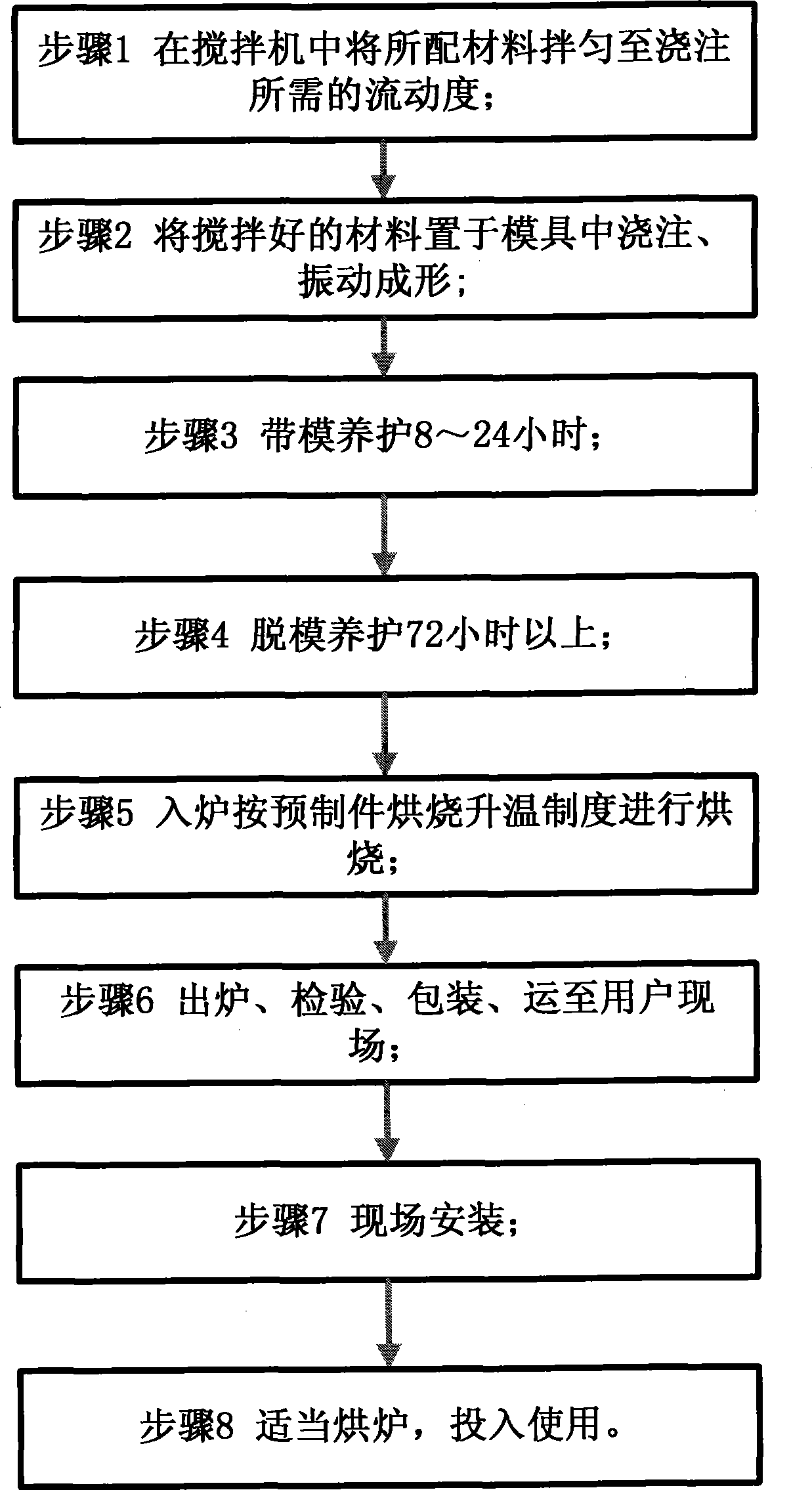

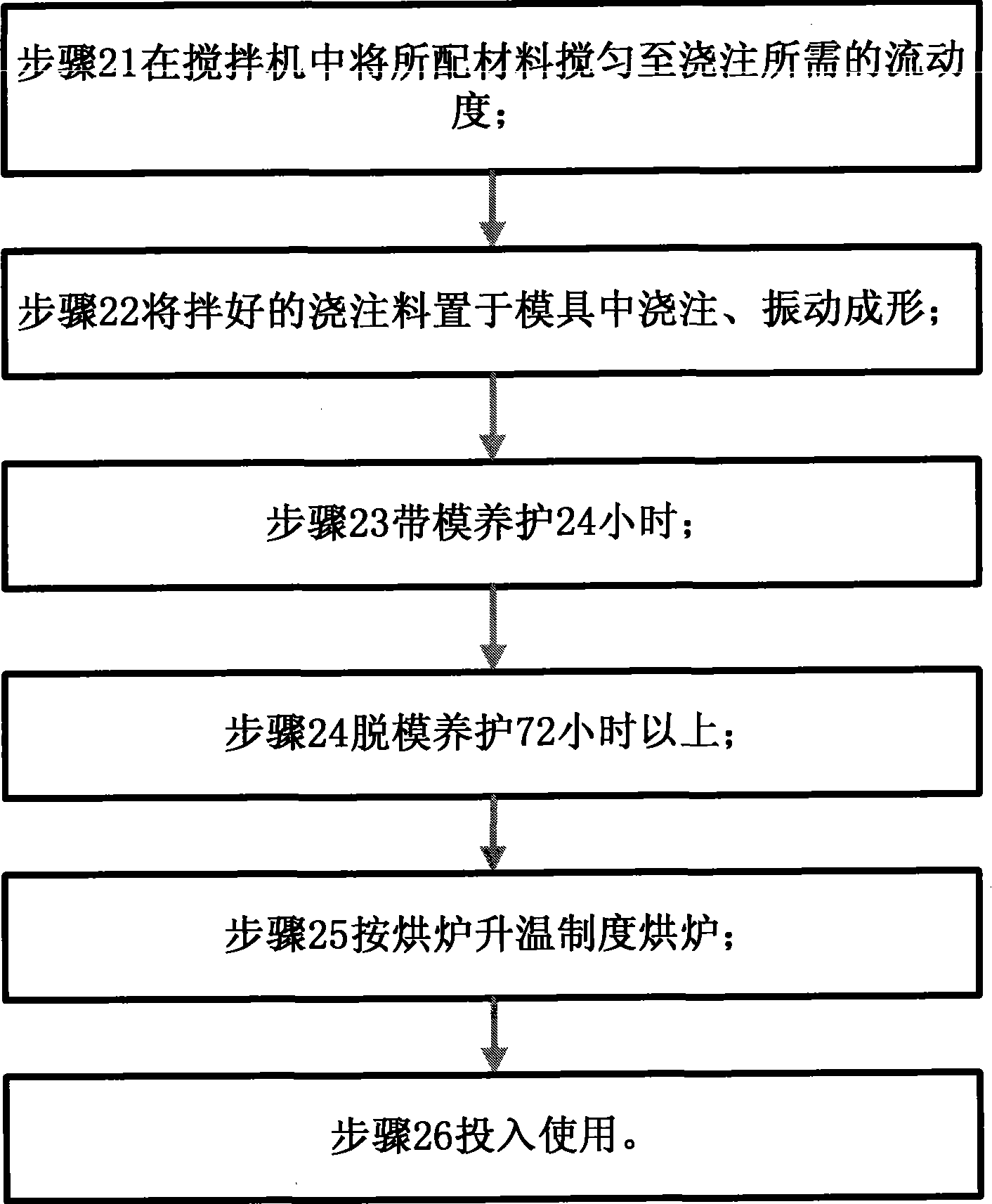

Method used

Image

Examples

Embodiment

[0053] High-precision aluminum alloy molten furnace external refining refractory castable, composed of aggregate, powder and additives, of which:

[0054] A. The aggregate consists of high alumina bauxite clinker with a particle size of 3-5mm accounting for 20% of the aggregate and powder mass; sub-white corundum with a particle size of 1-3mm accounting for 35% of the aggregate and powder mass. 0.5 ~ 1mm accounted for 15% of the sum of aggregate and powder mass sub-white corundum;

[0055] B. In the powder, α-Al203 powder accounts for 5% of the sum of aggregate and powder mass, sub-white corundum powder accounts for 5% of the sum of aggregate and powder mass, and titanium dioxide accounts for the sum of aggregate and powder mass 5%, barium sulfate powder accounts for 5% of the sum of aggregate and powder mass, CA70 pure calcium aluminate cement accounts for 10% of aggregate and powder mass,

[0056] C. The admixture sodium hexametaphosphate accounts for 0.15% of the sum of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com